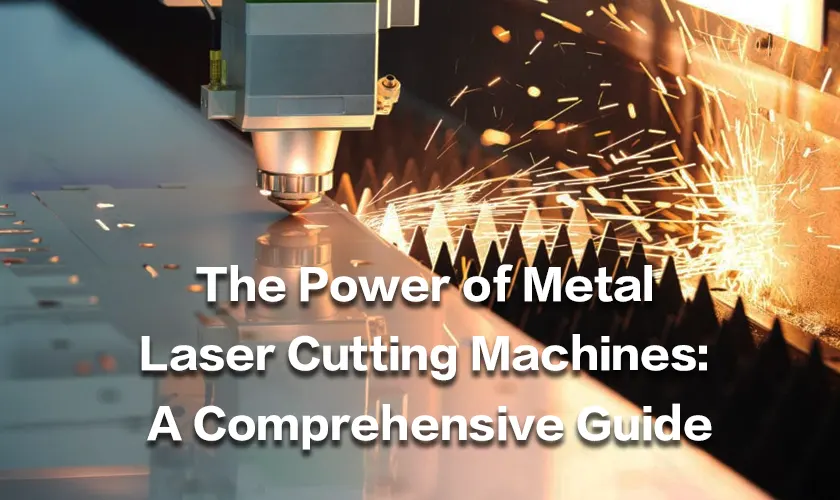

The emergence of metal laser cutting machines has enabled the processing of metal with greater amounts of precision and speed than was previously possible. There are now metal processing machines that can create complex designs as well as those for mass production. This exhaustive guide will discuss metal laser cutting machines and their limitations, applications and how to choose the appropriate one for you.

What is a Metal Laser Cutting Machine?

Cutting metal sheets and plates with a metal laser cutting machine is done with stunning accuracy with the aid of computer software capable of controlling a power laser beam. With the intensive heat focused on the material, the metal is liquefied or vaporized where a cut needs to occur. This process is computer automated which allows for the cutting of certain intricate designs and complex shapes. And this makes them suitable for a wide range of purposes, from laser cutting parts for electronics to large panel laser cutting for construction.

Metal laser cutting machines offer numerous advantages over traditional cutting methods like plasma cutting or water jet cutting:

- Precision: The laser beam can achieve extremely fine cuts, making it ideal for intricate designs and complex geometries.

- Speed: Compared to the conventional processes, laser cutting is much quicker which enhances productivity and reduces lead times.

- Versatility: The characters of these machines extend to the cutting of several metallic materials like steel, aluminum, stainless steel brass, and copper.

- Clean Cuts: Since the laser beam cutting technique makes a cut with a smooth edge and limited heat deformation, secondary finishing processes are less often necessary.

- Automation: There is a number of metal laser cutting machines that are automated, thereby enhancing the productivity level while minimizing the cost of labor.

Industrial Metal Laser Cutting Machines

Industrial metal laser cutting machines are designed for high-volume production environments, these robust systems deliver exceptional speed, precision, and reliability. The capability to process a diverse range of materials and thicknesses makes them a necessity for high-end industries such as automotive, aerospace, and general manufacturing.

The industrial metal laser cutting machines are designed in such a way that they perform at a higher level thanks to the features that are such as 12kW or greater laser sources powered fiber, cutting area of greater than 1500mm x 3000mm,such as 2000mm x 4000mm, 2000mm x 6000mm, 2500mm x 6000mm, loading and unloading systems which reduces the time taken to do load and unload the machine. Automated CNC control also enforces cutting consistency and neatness thanks to stiff constructs which secure resilience and accuracy of cuts for long. These machines use laser technology to cut the following metals; stainless steel, carbon steel, aluminum, copper, brass and titanium. These machines, in addition, can enable efficient production lines through incorporation with other manufacturing systems including robotic arms.

- Automation Equipment

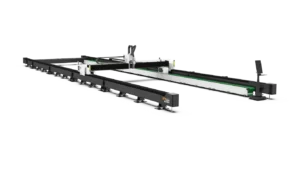

EA-series Automatic Loading and Unloading Laser Cutting Machine

- High Power Laser Cutting Machine

W-series Ultra Large Laser Cutting Machine

- High Power Laser Cutting Machine

L-series Ultra Large Laser Cutting Machine

- High Power Laser Cutting Machine

GP-Series High Power Laser Cutting Machine

Small Metal Laser Cutting Machines

Small metal laser cutting machines are ideal for companies that want to minimize costs and space without the need to lose reliability of how the cut is done. Such machines are now perfect for use by small and medium enterprises, workshops and also educational institutions. Compact as they are, these machines provide the type of versatility that most would not expect them to offer.

With the dimensions often being no more than 5 square meters along with starting price amounts of $15000, these machines are available for a large number of users. They are really simple to use, thanks to user-friendly interfaces and intuitive software that even a novice can handle. Although bearing lower output power lasers (1000W to 4000W) in general they are capable of cutting thin and medium thickness stainless steel, mild steel, and aluminum metals sheets. Hence, they are great for prototyping, sign making, and custom fabrication projects with emphasis on detail and accuracy. And also, because of their low operational costs and low upkeep requirements they are very rewarding to use.

- Sheet Metal Laser Cutting Machine

W-series Single Table Fiber Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

H-series Open Type Fiber Laser Cutting Machine

Professional Metal Laser Cutting Machines

Professional metal laser cutting machines represent the sweet spot for businesses seeking a balance of performance, versatility, and affordability. They bridge the gap between high-volume industrial systems and smaller-scale machines, making them ideal for a wide range of applications, from intricate high-precision cutting to medium-volume production runs.

These machines are able to provide speed and accuracy which means they can be employed in the performance of demanding jobs which have tight tolerances. They have multi-purpose cutting abilities for various metal types and thicknesses, such as stainless steel, carbon steel, aluminum, etc. Productivity is improved by mechanisms such as auto-focus and automatic nesting software. The investment in professional metal laser cutting machines is justified since they are strong and durable. In addition, their medium range power (usually 4000W to 6000W) and flexible configurations further cater to diverse business needs.

- Laser Cutting Machine

XT LASER 4000w fiber laser cutting machine for sale

- Laser Cutting Machine

XT LASER 6000w fiber laser cutting machine for metal

Sheet Metal Laser Cutting Machines for Sale

The market of sheet metal laser cutting machines for sale is large and varies in configuration and price ranges so as to provide solutions to different industries. Irrespective of whether your business needs an industrial system with higher machine power for large scale operations or small laser cutters for light operations, there is always a right machine for you.

There are certain steps to follow in order to find the best sheet metal laser cutting machine for sale. Take into account the sheet metal cutting capabilities of the respective machine which includes factors such as the maximum sheet size and thickness, the available laser power, cutting speed and precision. These will help in evaluating the machine’s production capacity. Do not forget to mention any extra options that depend on productivity, efficiency or any important feature such as auto-focus, automatic nesting soft software and fume extraction systems.

This guide discusses in detail the metal laser cutting machines, their applications and factors influencing the selection of the appropriate metal laser cutting machine. In case you are looking for a CNC laser cutting machine, a CNC laser cutter for metal or a fiber laser cutter for metal, look no further than XT LASER as we have several types of machines for you. We invite you to contact us in order to explain further about our products and the solutions we provide to our customers’ businesses.

- High Power Laser Cutting Machine

L Series Large Laser Metal Cutting Machine

- Sheet Metal Laser Cutting Machine

G-series Fully Enclosed Exchange Table Fiber Laser Cutting Machine

How Much Is a Laser Metal Cutting Machine?

If you’re considering purchasing a metal laser cutting machine, it isn’t surprising that you’re hesitant because this is a major investment. Asking how much does the pricing of these machines depend on is also important. They may range from $10,000 for the small laser cutting machines price, to over $100,000 for the top of the line industrial systems. Here’s a breakdown of the key elements affecting the fiber laser cutting machine price:

The Amount of Laser Power and the Cutting Capacity

What is the most effective laser source will have the most decisive effect when determining pricing. Lasers with higher power measured in kW are more costly but have the ability to cut thick materials and high cutting speeds. Remember the types of metals you are going to cut and what their thickness is, so that you know what laser power is required for the job.

Cutting capacity which involves the maximum sheet size is also one of the factors influencing the price of cutting machines. Larger cutting areas allow larger metal sheets to be processed making the production more efficient, however, this adds to the price.

Features and Automation

Enhanced features greatly influence the price. Automated loading and unloading systems make workflows more efficient, however, these come at an additional cost. Software technologies like automatic nesting, which minimizes the waste of materials, also bear a price tag. The use of high-speed cutting heads, specialized nozzles and sophisticated control systems can also add more onto the price.

Brand Reputation and Build Quality

Usually, reputable brands with a good history of reliability and performance will charge higher prices for their products. There is a greater sense of protection and assurance in the investment when one decides to invest in the likes of the established brand XT LASER. Look for the warranty provided by the manufacturer, the after sales services and whether spare parts are available.

Customization and Configuration

Certain models of metal laser cutting machines for sale are characterized by a high level of customization. Final price may be affected by some specialty options like rotary axes for cutting cylindrical objects or integrated fume systems. Suppliers should be informed about the needs of the clients so that they can provide the best configuration for the applications.

Tips for Evaluating Costs: As you proceed to obtain a laser cutter, make sure you compare prices from different suppliers so you can find the best one that can meet your desired specifications like cutting features and requirements. And so:

- Request detailed quotes: Do not be afraid to check and request several suppliers giving the features you want and the depth of cut required for the material. With this, you will have a number of quotes to compare and choose the best from the different suppliers.

- Take account of operating costs: Include periodic costs of consumables including assist gas and lenses, together with maintaining services which develop.

- Evaluate return of investment: Look at how much increase in sales, decrease in labor and all these factors will be altered by introduction of a laser cutting machine into the firm.

If you understand these aspects clearly and carry out the evaluation effectively, you should be able to locate the precise metal laser cutting machines for sale, most appropriate to your needs, and improving your return on investment.

How to Choose the Best Metal Laser Cutting Machines?

When choosing the best metal laser cutting machines for your company, there are a number of factors that needs narrow attention.

- Material Type and Thickness: Because of this, different lasers are suitable for cutting certain types of metal depending on the material thickness. A good example is that a fiber laser cutter for metal performs great when cutting thin to medium thickness metals while CO2 lasers do well with thicker materials.

- Cutting Speed and Precision: While looking for the machines, take into account your production requirements as well as the required degree of precision of your applications. If the production of parts is to be done in large volumes and faster, then the machine that has higher speed cutting will be required.

- Budget: Decide on what your budget will be and try to find machines within that budget. Do not forget to include costs that will be involved in consumables, maintenance as well as training.

- Features: Compare different machines that are in the market to see what features they have to offer and select those that are necessary for you. Potential features include CNC laser cutting capabilities, automatic nesting software, fume extraction systems, etc.

- After-Sales Service and Support: Go for a supplier who has a good reputation in the market and provides all round after sale service and technical assistance. In regard to this, it is very important for the operational and downtimes of the machine to be as low as possible.

By carefully evaluating these factors, you can choose the best metal laser cutting machines that meet your specific needs and deliver optimal performance.

Best CNC Laser Cutter for Metal

When it comes to precision, efficiency, and versatility of the metal fabrication processes, the best recommendation is a CNC laser cutter for metal from XT LASER. These machines are designed to perform well while maintaining high-quality output thus suitable for a great number of applications. But what makes XT LASER the best CNC laser cutter for metal? To begin with, let us analyze the critical advantages of XT LASER.

Advanced Technology and Precision

The range of CNC laser cutters designed and manufactured by XT LASER is equipped with fiber laser cutting technology. It is known that fiber lasers are characterized by high energy efficiency, superb quality of beams, and considerable operational lifetimes. This results in high cutting accuracy, high cutting speeds, and low heat affected zones on your workpieces during the cutting process. Whether it is a need to cut complicated shapes or high-precision parts with close tolerances, one will get what he wants with laser metal cutting machine of XT LASER.

Wide Range of Applications

CNC laser cutters for metal for sale from XT LASER are wide so as to cut different types and thickness range of materials. From stainless-steel and carbon steal to aluminium, copper and brass, these machines can handle various projects. Due to these properties, they are applied in various industries, such as automotive, when there is a need to cut out complex shapes for the body of cars, exhaust systems, and cabin parts.

- Aerospace: Fabricate high-precision engineering components for aeroplanes and spacecraft.

- Electronics: Design complex materials such as circuit boards and electronic devices.

- Medical: Fabricate and assemble a variety of advanced medical instruments and devices.

- Signage and Fabrication: Fabricate unique dosage forms, integrated designs, signs, interior items and artistic metalwork.

User-Friendly CNC Control

XT LASER laser metal cutters are operated by easy and efficient CNC (Computer Numerical Control) systems. Such systems can control cutting parameters, including cutting speed, power, and gas flow. With these features, complex cutting paths can be easily programmed through interface and intricate designs can be cut as well. Most importantly, these machines require little training for most people to be able to use them in due course.

Increased Productivity and Efficiency

XT LASER designs its machines with the perspective of improved productivity and economy. Many models include also :

- Automatic nesting Software: This saves resources and optimizes waste materials by arranging cutting patterns strategically.

- Auto focus systems: These systems help in maintaining the required quality of cutting as the laser concentration is automatic.

- High speed cutting heads: It is possible to enhance cutting speeds with an aim of increasing outflow.

- Automated Safe System: It becomes efficient to manage operations integrating manual intervention saving on manpower costs.

Total Support and Services

Choosing XT LASER means not only buying a great quality CNC laser cutter for metals. It also entails complete support and service. XT LASER provides:

- Booming customer technical support: Questions and instructions from technicians with experience are at your disposal.

- Step by step training: Check that every -operator is properly trained to operate your machine optimally.

- Effective maintenance & repair: Reduce downtime thanks to quick and efficient maintenance and repair services.

If you are in search of the CNC laser cutter for metal, with advanced technology, varied capabilities and easy operation, coupled with quality support, XT LASER is ideal choice. Contact XT LASER today to study the range of CNC laser cutters for metal for sale and how these items can be relevant for your business.