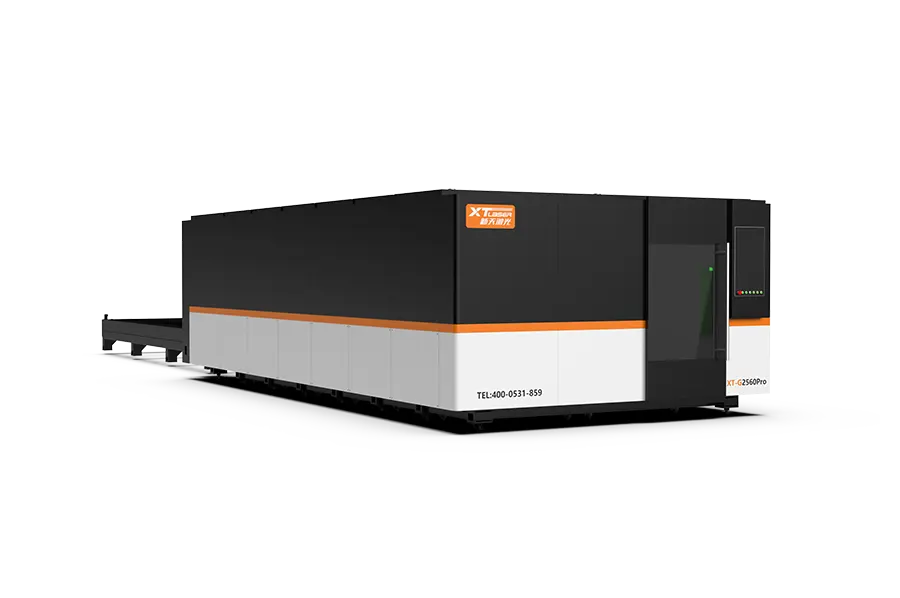

Leading Laser Cutting Machine Manufacturer in China

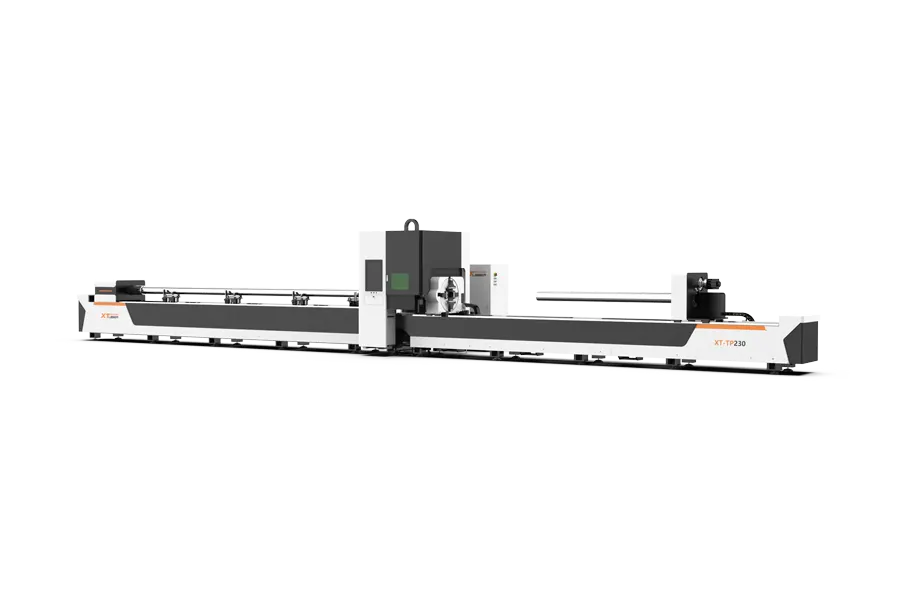

Specialized in laser cutting machines, laser tube cutting machines, laser welding machines, laser marking machines, and laser cleaning machines. Reliable quality and cost-effective.

The Best Fiber Laser Machines

XT LASER is a manufacturer specializing in fiber laser cutting machine, providing one-stop solutions, including laser cutters, laser marking machines, laser welding machines, and laser cleaning machines.

XTLASER-Professional Laser Cutting Machine Supplier

XT LASER has been deeply involved in the laser cutting industry since its inception in 2004. It has been committed to providing customers with state-of-the-art laser cutting, marking, welding, and cleaning equipment worldwide. We have a team of highly skilled engineers, technicians, and industry experts dedicated to advancing laser technology.

To date, XT LASER can provide the most advanced and comprehensive laser processing solutions to customers worldwide. A commitment to excellence, efficiency, innovation, and customer-first sets XT LASER apart from other laser cutting machine manufacturers.

XT LASER provides online support at any time. Whether it's pre-sales inquiries or post-sales support, there will be a professional to solve your problems in real time.

XT LASER builds a global after-sales network, realizing 12-hour on-site after-sales and instant video after-sales. No need to worry about after-sales problems when you choose XT LASER.

We focus on the cost-effective, and strive to provide customers with high-quality products and services, while minimizing the purchase cost and improving economic efficiency.

For Various Applications

laser welding

Laser welding technology can skillfully join two identical or different metals together.

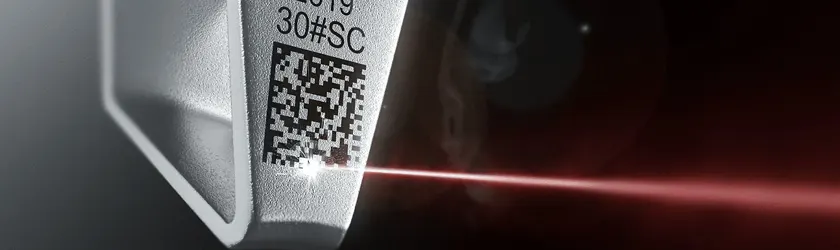

Laser Marking

Deep engraving of patterns or printing of bar codes, logos, badges, etc. on the surface of metal, glass, wood, ceramics and so on.

Laser Cleaning

Environmentally friendly and non-destructive cleaning of oil, rust, oxidized layer, dust, welding slag, etc. on the surface.

Still have a lot of doubts? Contact us for support!

FAQs

How much does a laser cutter cost? What are the factors that affect laser cutting machine price?

Laser cutting macine price depends on several factors. Generally speaking, the cost of an entry-level desktop laser cutting machine is a few thousand US dollars, industrial laser cutting machine price ranges from tens of thousands of US dollars to hundreds of thousands of US dollars, the specific laser cutter price from a variety of factors to consider.

The main factors affecting laser cutting machine cost are:

- laser power

Laser power plays a decisive role in the cutting speed and thickness of the machine. The higher the laser power, the faster the cutting speed and the better the ability to cut thicker materials. Therefore, for the same brand of laser, the higher the power, the higher the price, and thus the higher the cost of the laser cutting machine.

- Type of laser source

The common lasers used in industry are fiber lasers, CO2 lasers, and YAG lasers. Different types of lasers have different characteristics, so their materials and applications will vary. The choice of laser source affects factors such as cutting speed, energy efficiency, and maintenance requirements.

- Beam quality

The quality of the beam will have an impact on the cutting accuracy of the laser cutter. A high-quality beam profile results in better cutting accuracy and edge quality. Especially for industries that require more detail in their cuts, a good beam quality can save them the time and cost of secondary processing.

Apart from the above-mentioned points, the size of the machine, automation features, motion control system, etc., will have an impact on the price of the laser cutting machine.

Therefore, customers need to consider these factors when choosing a laser cutting machine to ensure that they get the best cutting results while maximizing the efficiency of their metal laser cutting machine.

What materials can be processed by fiber laser cutting machine?

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

What payment methods do you support?

XT LASER can accept USD, EUR, AUD, CAD, GBP, and many other payment currencies, and supports T/T, PayPal, cash, credit card, Western Union, L/C, and many other payment methods.

Which CNC laser cutting machine is right for me?

Not every customer knows enough about laser cutting machines, and you reading this may be facing this kind of trouble.

XT LASER understands the real situation of each customer and tries to figure out their actual needs. If you are not sure which machine is right for you, you can contact us. We will arrange for the most professional consultants to advise you.

Our professional sales team will provide you with customized solutions and professional laser cutting advice based on your metal working needs, budget constraints, and other factors to help you choose the most suitable laser cutting machine.