Laser Welding Machine Price Guide: Find the Perfect Machine for Your Needs and Budget

Laser welding machines has transformed a number of industries as these machines are known to deliver exquisite precision, enhanced speed and great efficiency. However, with a wide range of models available, understanding laser welding machine price variations and finding the perfect fit for your needs and budget can be challenging. This article will help you understand factors affecting laser welding machine price, and assist you in choosing the most appropriate machine to fulfill your requirements.

Factors Influencing Laser Welding Machine Price

Several factors contribute to the overall laser weld machine price. Understanding these factors will help you make an informed decision and choose a machine that offers the best value for your investment.

- Laser Power and Type: Power laser sources measured in watts or kilowatts are crucial parts of pricing. If a higher power is attained costlier, the laser with its complementing components would be. Lasers can be classified into different types such as fiber lasers, CO2 lasers, and solid-state lasers. Higher power lasers can weld thicker materials and offer faster welding speeds, but they come at a higher cost. For instance, a 1kw laser welding machine price will differ significantly from a 1500w laser welding machine price.

- Welding Speed and Precision: Machines with higher welding speeds and greater precision often come with a higher price tag. These features are excellent for applications plenty of intricate welds are required.

- Automation and Features: Automatic laser welding machines have seam tracking, robotic integration, and vision systems, they are higher than handheld laser welding machine price. As the level of automation and unique features change, invariably the price of laser welding machine will be affected.

- Brand and Manufacturer: Trademarks and manufacturers that are known to the market raise the price of their machines because of their quality, their dependability, and their after-sales services, it is advisable to compare laser welding machine price from different manufacturers so as to verify their cost and more their performance.

- New vs. Used: Used laser welding machines are cheaper alternatives and are advantageous for companies with limited resources and cash flows. However, used machines should be carefully assessed for possible wear and tear as well as possible maintenance expenses.

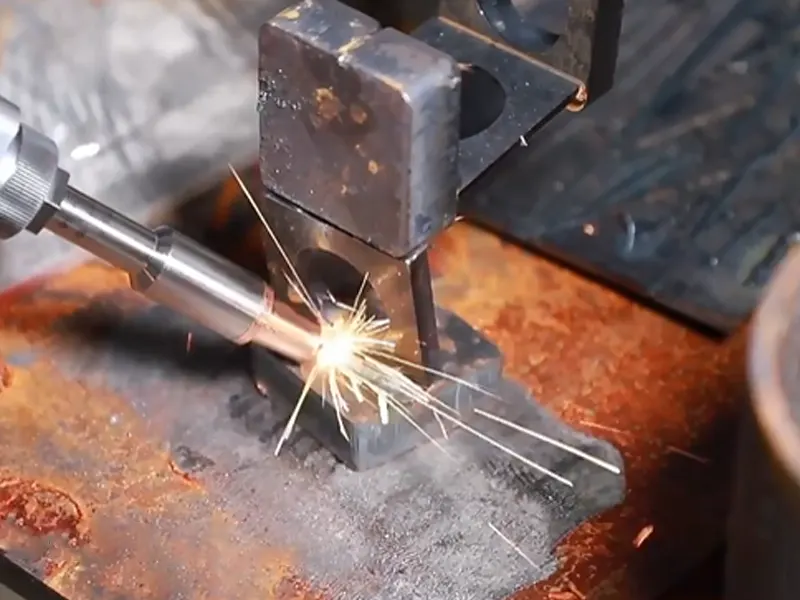

Weld

Clean

Cut

Clean weld

Types of Laser Welding Machines and Their Prices

Laser welding machines are available in different types that are intended for different purposes and different price ranges. Here’s an overview of some common types and their approximate price ranges:

- Handheld Laser Welding Machines: These portable and versatile machines offer flexibility for various welding tasks. Handheld laser welding machine price, for example, is from 3000 USD to 5000 USD for the basic model of the laser welding machine. You can also find some variations in the terms, there is the handheld fiber laser welding machine price, hand laser welding machine price, and also handle laser welding machine price.

- Small Laser Welding Machines: Compact and designed for smaller workspaces, small laser welding machine price generally falls in the lower range compared to larger, industrial-grade machines. Expect to pay between $10,000 – $50,000 for these machines, depending on the laser power (typically ranging from 500W to 1500W) and features like automated seam tracking.

- Portable Laser Welding Machines: Similar to handheld models, portable laser welding machine price varies based on portability, power, and features. They offer convenience for on-site welding and repair applications. Prices typically range from $8,000 – $10,000.

- 3 in 1 Laser Welding Machines: 3 in 1 laser welding machines combine the functionality of welding, cutting, and cleaning but only require the overhead of one machine. 3 in 1 laser welding machine price is usually higher due to their multi-functionality, starting around $5,000 and going up to $10,000 or more depending on the configuration and power of the laser.

- Automatic Laser Welding Machines: Designed for high-volume production, automatic laser welding machine price can be significantly higher due to their advanced automation features and high welding speeds. These machines can range from $20,000 to well over $30,000, depending on the complexity of the system, the level of automation, and the laser power.

But in addition to those features and models, final price for a laser welding machine depends on much of factors including the supplier along with the specific model and brand so you might want to consider reaching out to multiple suppliers making it easier to find the best deal.

Choosing the Right Laser Welding Machine for Your Budget

When you go out to purchase a welding laser machine, we recommend that you prioritize your budget, features, and application requirements. Here are some helpful steps in finding suitable products:

- Define Your Needs: Clearly outline your welding requirements, which include materials, thickness, level of precision, and production volume. This will help you narrow down your options.

- Set A Budget Amount: Note your budget limitations, and search for machines within that budget amount. Consider factors such as maintenance, consumables, and future upgrades.

- Compare Between Pricing and Features: Different models and brands have differing features, specs, and pricing. Look for machines that offer the best value for your investment.

- Consider Used Machines: If your budget is limited, explore used laser welding machines. Ensure you thoroughly inspect the machine and assess its condition before purchasing.

- Seek Expert Advice: XT LASER is a professional laser welding machine supplier. This makes them ideal candidates to help you in purchasing suitable machines.

Conclusion

Regarding laser welding machines, it is important to conduct thorough research and consider various factors to find the most suitable one concerning both requirements and budget. Understanding the different kinds of machines, and factors that affect the price of a machine and following the advice provided in this article will help you in buying a machine that will perform and be worth the cost for your business. Remember to prioritize your specific requirements, compare prices and features, and seek expert advice when needed.