The fiber laser marking machines has become a new revolution in the industrial marking system due to their high accuracy, speed and versatility in working. It is machines that has a fiber laser source mounted that can create permanent marks mainly on metals. Thus, be it automotive, electronics, aerospace or jewelry industries one can benefit by knowing the fiber laser marker machine capabilities for your marking requirements to improve your marking processes making it more efficient and higher quality.

What is a Fiber Laser Marker Machine?

The fiber laser marker machine is a device that falls inside the radar of laser marker systems that contains a fiber laser to provide high energy density beam of laser which is then focused on the surface of a material to provide everlasting markings, engravings or etching. In order to obtain the required marking, a specific setting of the laser beam, in terms of its path, strength and pulse length is required.

How does a Fiber Laser Marker Machine Work?

There are three main components in the working process of a fiber laser marker machine. These are:

- Laser Generation: A fiber laser also doped with rare earth element, typically Yb, is used for laser. The laser is tuned into a diode laser to pump the fiber and cause the atoms in the fiber to excite and then emit the photons. The result is that these photons are amplified within the fiber which results in a laser beam with high intensity.

- Beam Delivery: The marking head receives the laser beam generated through a fiber optic cable. This cable helps transmit the laser beam over long distances with little power loss and beam distortion.

- Beam Focusing: There are multiple optical devices like lens and mirrors in the marking head that focus the laser beam onto the material. Spot size of laser beams is influenced by lens’s focal length which determines the resolution and precision of the markings.

- Material Interaction: A focused laser beam applied to the material causes thermal effects that are localized to a small volume of the material, causing heating, melting, or even vaporization. This ring processes forms the desired mark, engraving or etching on the workpiece. The power of the laser, duration of the pulse, and other characteristics of the material will determine the depth and other characteristics of the marking.

- Motion Control: Marking head is integrally located with a marking motion system which in most cases is a galvanometer scanner or an XY table and this gives the operator the ability to accurately direct the laser beam to different parts of the workpiece surface. This allows for complex patterns, designs, and text to be created.

Advantages of Fiber Laser Marker Machines

Fiber laser marker machines have several advantages over other conventional methods of marking which include mechanical engraving, inkjet printing, chemical etching, etc.:

- High Precision: The control over the movement of fiber laser engraver machine for metal and the focused nature of the laser beam allows it to engrave minute and complex markings with a high degree of precision.

- High Speed: The processes do not move at low speeds; hence, marking with these machines is rapid, allowing a vast amount of parts to be marked within less time. This enhances productivity and reduces cycle time as compared to traditional methods.

- Non-Contact Process: The processes of branding do not require touch and therefore physical contact with the material is not necessary. This not only protects fragile components from harm but also eliminates the damage caused by friction and other problems related to conventional branding techniques.

- Permanent Marks: There is no wearing off and scratching of the marked area with China fiber laser marking machines. Such marks are extremely durable and can withstand heat, chemicals, and other harsh conditions which might lead to a wearing off. This guarantees traceability and identification of the marked parts for an extended period.

- Versatility: Most green fiber laser marker machines can mark with high precision a range of materials such as metals, plastics, ceramics, and composites. The adaptability enables them to be useful in different areas in various industries.

- Low Operating Costs: The operational costs that are incurred when using China fiber laser marker machines are low due to the efficiency they have and the fact that there is low maintenance which is needed.

They use less power than conventional marking techniques and they don’t need inks or chemicals as consumables.

Applications of Fiber Laser Marker Machines

Using these machines, professional fiber laser marker machines efficiently engrave or etch marks on various types of materials within industries such as:

Automated Industrial Manufacturing: Tools for marking parts with serial numbers, barcodes, logos, and other identification information for quality management purposes.

Electronics: The marking of patterns and identification codes on electronic instruments, circuit boards, and semiconductors.

Automotive: Marking car parts like engine blocks, component chassis, and sometimes interior trim with VIN numbers and other identification markings.

Aerospace: Marking aerospace components with identification codes and relating critical information like serial numbers for identification.

Jewelry: Complex patterns, designs, and names are engraved on the jewelry.

Marking: Medical devices are stamped with registration numbers, manufacturing dates, and other information regarded as regulatory.

Packaging: Packaging materials are labeled with barcodes, logos, and product details for branding purposes and supply chain tracking.

Tools: Tools and dies are imprinted with identification, volume number, and dates when they were manufactured.

Varieties of Fiber Laser Marker Machines

Fiber laser marker machines can be supplied as per different configurations in order to address the different application requirements.

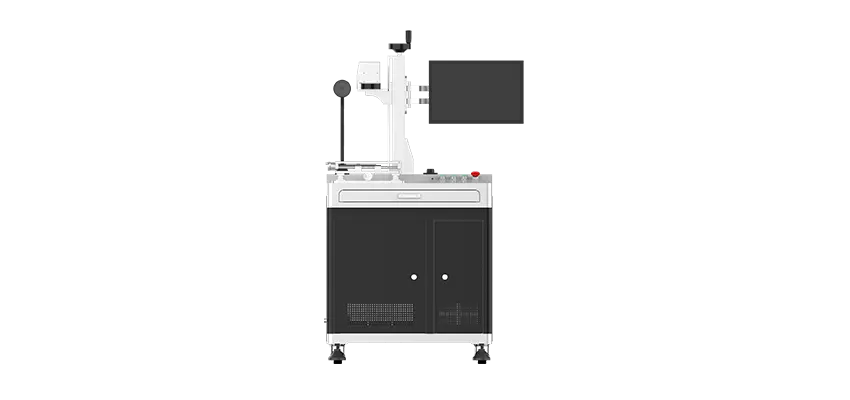

Desktop Laser Marking Machines: These machines use an XY table to move the workpiece under the laser beam, allowing for precise marking of larger parts or multiple parts simultaneously. They are suitable for applications requiring high accuracy and large marking areas.

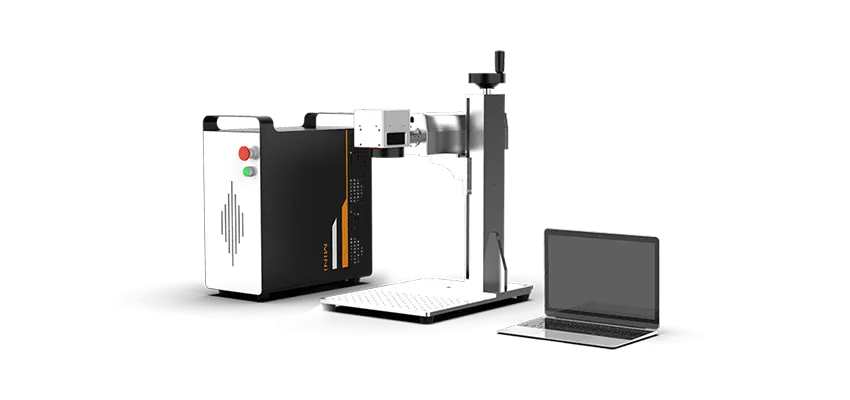

Portable Fiber Laser Marking Machines: These types of machines mark with laser having an XY type of table which moves the workpiece so that laser is perpendicularly orthogonal allowing marking of large parts in a single laser beam or multiple parts and laser beams at the same time. These kinds of machines are used for applications which have high power requirements and very large marking areas.

Lightweight & Compact China Portable Fiber Laser Marking Machines: These fibers are not heavy machines enabling the framework to be very light. They can also be moved very easily making them suitable for products that can be marked off site and have very little space.

Enclosed Fiber Laser Marking Machines: Such kinds of machines have interior marking enclosures that prevent marking and keep escaping fumes or debris. Machines like these will be very suitable where materials are hazardous or needing a clean environment for many applications.

Choosing the Right Fiber Laser Marker Machine

One of the most important considerations when choosing a fiber laser marker machine is undoubtedly the efficiency level, the return on investment and finally the performance. There is hardly a standard machine type in terms of design and configuration. So, several important questions must be answered in details:

Material and Application

- Material: Materials absorb laser energy differently so different materials will give different results. Whenever you use fiber laser marker machines, you’re best using them for metals such as steel, aluminum, brass and even precious metals. They’re even able to mark certain types of plastics and ceramics. In case, you handle organic materials like wood or leather, CO2 laser marking machine will suit you far more.

- Marking depth and contrast: Before using the marker, these questions should be asked. What Kind of Marking Depth and Contrast is going to be applied? Does your firm provide services for superficial engravings, deep marks or color shifts with high contrast? It’s very important to know the power of the laser as well as the nature of the material which is going to be used.

- Application Requirements: Your task is In many instances, to specify the requirements. What do you have to mark? For instance, is it the serial number, the barcode, the logo, intricate designs or even the data matrix code? The details and size of the marking will determine the machine to be used as well as the machine parameters.

The power and wavelength of the laser

- Laser Power: The laser power which is in Watts is the determinant of the speed and depth of the mark. With the increase in power of a laser the depth and speed at which the marking is done increases but the cost also gets high. While making this consideration for the amount of parts to be marked, the required speed also has to be factored.

- Wavelength: The common utilization of lasers is the fiber laser markers with nominal strength of 1064nm for marking metals. Some fiber laser marker machines can provide different wavelengths or may use frequency doubling to mark some plastics with the desired result, or colors on metals.

Marking Area and Field Size

- Marking Area: The first thing you have to do is find the bigger measurement of the bigger part which has to be marked. That will also affect the working area size as well as the counting time of the marking head.

- Field Size: The max. area of the line which can be marked through a step in a number up to max in count number is called field size. It is much better if the parts to be marked are of larger size or multiple marking is required and sizes with larger field size will do the job. Marking resolution may be interfered with by larger sizes of field.

Marking Speed

- Marking Speed: The marking speed is the movement speed which the read-write head moves while conducting the marking process and can be determined in meters per second. It has an impact on the output of the total steam and the total work done per unit of time. If higher amounts of marking speeds, this is to be required in mass production.

Machine Design and Generated Patterns

- XY Table Fiber Laser Marker Machines: This machine can mark a single larger component or smaller parts simultaneously It possesses high accuracy and is used for applications involving deep engraving or cutting.

- Portable Fiber Laser Marker Machines: Definitely not the same as the above-mentioned machines, these units are lightweight and easy to carry, making them desirable for operations where onsite marking is required or space is restricted.

- Enclosed Fiber Laser Marker Machines: These devices enable a safe marking environment especially when working with skinny materials and applications associated with hazardous fumes.

- Additional Features: Additional features to choose from include: rotary axis attachments for marking cylindrical objects, vision systems for automatic parts alignment and a plethora of software features to create and edit marking designs.

Pricing and Complete Cost Engagement

- Cost of Purchase: According to the technical functions, power, and features, many manufacturers produce various fiber laser marking machine price at different levels.

- Cost of Operation: Take note of the electric energy, maintenance, and other possible consumables that may be required like lenses or protective windows.

- Profitability: One way of estimating profitability is to think of the operating efficiency, quality of products produced, and labor costs that may be us ed when deploying a fiber laser marker machine which bears some costs.

Market Presence and Assistance Provided by the Supplier

- Experience of Supplier: In this regard, a good supplier who has vast knowledge of the operations of laser marking is recommended.

- Support Services: Support services to customers by the fibre laser marking machine supplier such as relevant technical assistance, training and after-sales service should be guaranteed.

- Warranty and Maintenance: Ask with respect to the warranty period and scope of maintenance services to guarantee future use of your fiber laser marker machine.

By taking note of these factors closely and discussing with the suppliers who have vast experience, you can be able to select the best fiber laser marker machine that efficiently suits your needs and enables the realization of your marking goals.

Conclusion

Today’s fiber laser marker machines have changed the perspective of marking and engraving of various materials; they are quick, versatile and exceedingly accurate. Now, because of their ability to generate high quality, permanent marks usable on a variety of materials, they are helpful devices in many fields. Firms who have an idea of the functions and uses of fiber laser marker machines will facilitate their marking process increase product quality and production efficiency.