In today's fast-paced manufacturing industry, efficiency and precision are the keys to success. Whether you're a large manufacturing facility or a small studio, you need processing equipment that meets your specific needs, and low power fiber laser cutting machines are becoming the preferred choice for more businesses and individuals because of their superior performance and wide range of applications.

Low power fiber laser cutting machines, literally mean laser cutting machines with lower power output. Compared to high power laser cutting machines, they are more suitable for processing tasks that do not require as much cutting thickness and cutting speed.

However, this does not mean that low-power fiber laser cutting machines are useless. On the contrary, low-power laser cutting machines have many unique advantages. It is precisely these advantages that allow them to excel in specific areas.

So, exactly who and what industries’ processing needs can low power fiber laser cutting machines address? This article will delve into the advantages of low-power laser cutting machines, application scenarios, and how to choose the right equipment for you.

Understanding low power fiber laser cutting machine

What are the advantages of low power fiber laser cutting machines in the field of laser cutting? What are the limitations that restrict their use?

What is a low power fiber laser cutting machine?

Low power fiber laser cutting machine usually refers to 1500W and below fiber laser cutting equipment, and high power fiber laser cutting machines work on the same principle, are the use of fiber lasers to generate high energy density laser beams, the laser beam focuses on the surface of the metal workpiece, to make it melt or vaporize, to achieve the purpose of cutting.

Advantages of low power fiber laser cutting machine

Although low power laser cutting machines are inexpensive, their processing capability should not be underestimated. With their unique advantages, they stand out from the crowd of processing equipment and have become the right hand of more and more companies, becoming the mainstay of many metal manufacturers.

- Cost Effectiveness

Low power laser cutters are much cheaper to acquire compared to high power laser cutters. If a low power laser cutter is sufficient for your cutting needs, it is a unique choice. After all, in the long run, the advantages of high efficiency, low maintenance cost, energy saving, and environmental protection are enough to save a lot of money for your business and realize higher economic benefits.

- Easy to Operate

Low-power laser cutting machines are simpler to both install and operate. Usually equipped with an automated control system, the operation interface is simple and intuitive. Even inexperienced operators can easily learn. In addition, maintenance is also relatively simple, without the need to replace consumables as frequently as other cutting equipment.

- High precision and narrow slits

Low-power laser cutting machines use a focused laser beam to cut with micron-level precision. It can form fine and dense holes on the metal surface, and the dense holes are connected to form extremely fine cuts with smooth and burr-free edges, eliminating the need for subsequent grinding and processing, and improving processing quality and efficiency.

- Fast cutting speed

Despite the low power, the fiber laser still has the characteristics of fast cutting. Especially when cutting thin metal plates, its processing speed and effect can be comparable to high-power equipment. This makes it an ideal choice for efficient production.

- Wide processing range

Fiber laser cutting machines can cut almost all common metal materials, including stainless steel, carbon steel, aluminum, copper, alloys, and more. This wide applicability is just like the wide range of metals that can meet the needs of different industries. From mechanical manufacturing to advertising production, all can be accomplished through it.

Limitations of low power fiber laser cutting machines

Despite the numerous benefits of a low power laser cutter, this does not mean that it is omnipotent. The restricted cutting thickness and speed are very obvious limitations. Due to the low power of the laser it uses, it is not possible to cut metal materials that are too thick. In addition, speed is necessarily reduced when cutting relatively thick materials.

- Cutting Thickness Limitations

Due to their low power, low power fiber laser cutting machines inevitably have some limitations in terms of cutting thickness. Generally speaking, the cutting thickness of low power laser cutting machines is 10mm or less for metal sheets. If you need to cut thicker materials, higher power fiber laser cutting machines are a better choice.

- Poor cutting results for highly reactive materials

For some highly reactive materials, such as aluminum and copper, the cutting effect of low power fiber laser cutting machines will be greatly reduced. This is because the laser beam is easily reflected by the material and loses energy, which in turn affects the quality of the cut.

Applications of Low Power Laser Metal Cutting Machines

Despite their low power, low power laser cutting machines can be used in a wide range of applications, providing efficient and accurate processing solutions for a variety of industries. Let’s explore the applications of low power laser cutting machines and see how they energize businesses.

- Small processing plant

For small processing plants, a low-power fiber laser cutting machine is undoubtedly the ideal choice. Easy to operate, low maintenance, cost-effective, etc., is simply tailor-made for small businesses. Whether it’s cutting metal parts or fabricating metal cabinets, low-power laser cutting machines are up to the task, of helping businesses achieve flexible and efficient production.

- Personalization

As consumers demand more and more uniqueness and creativity in products, low-power fiber laser cutting machine is characterized by their high precision and flexible customization. It can present all kinds of creative designs on the products perfectly. Whether it is a customized cut shape or a unique artwork, low power fiber laser cutting machine can help you realize your creativity and create your exclusive products.

- Artistic Creation

The low power fiber laser cutting machine offers unlimited possibilities for artists. It can engrave intricate patterns and fine textures onto common metal materials to create stunning works of art. Whether it’s a sculpture, a decorative object, or an installation, low power fiber laser cutting machines help artists bring their inspiration to life.

- Other Light Processing Industries

In addition to the above, low-power fiber laser cutting machines are also widely used in light processing industries such as advertising, modeling, and medical device manufacturing. It can quickly and accurately complete various cutting and engraving tasks, improve productivity, and reduce processing costs.

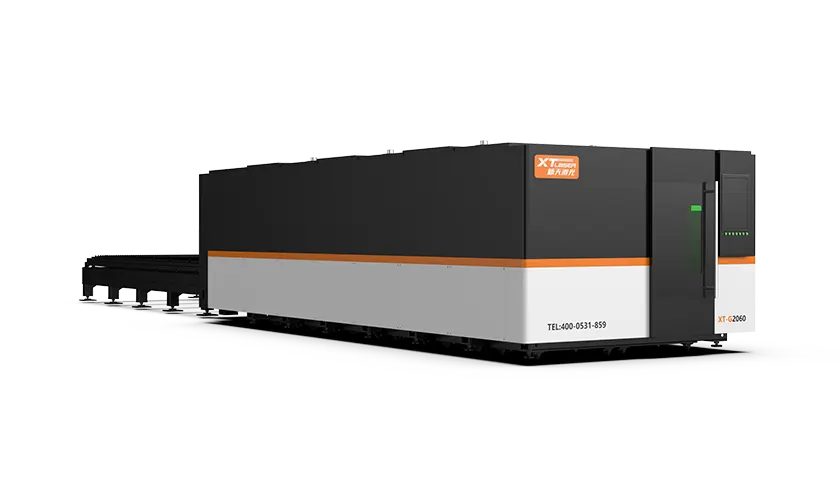

1500W laser cutting machine

XTLASER, as an experienced laser cutting machine supplier, provides low, medium, and high power fiber laser cutting machines for customers from all over the world. 1500W laser cutting machine opens the door of laser processing for small and medium-sized enterprises and individual users with its affordable price and outstanding performance. The 1500W laser cutting machine opens the door to laser processing for small and medium-sized businesses and individual users.

The 1500W laser cutting machine can cut carbon steel, stainless steel, aluminum alloy, and other metal materials with a thickness of less than 10mm, which can be considered if you do not require high cutting speed and depth. You don’t need to invest too much money to get a 1500W laser cutting machine and experience the high precision and efficiency of laser processing.

2kw fiber laser cutting machine

China 2000w laser cutting machine Compared with 1500W laser cutting machine, it is capable of cutting thicker materials and more complex processing tasks, which is the ideal choice for enterprises pursuing higher productivity and is widely used in machinery manufacturing, automobile parts processing, sheet metal processing, and other fields.

2 kW laser cutting machine is suitable for cutting 20mm thick carbon steel, stainless steel, aluminum, copper, and so on. The cutting seam is oxidized, the heat-affected zone is small, and the processing quality is high.

3kw laser cutting machine

3kw laser cutting machine with its strong cutting ability and excellent processing efficiency, has become a hot product in the middle and low power laser cutting machine. 3kw laser cutting machine price is much lower compared with the high power laser cutting machine, the cutting speed and the cutting effect are not worse than the high power cutting machine.

3000w metal furniture laser cutting machine is widely used in the furniture industry and is a good choice for improving productivity. Numerous 3000w metal furniture laser cutting machine factories provide you with a diverse range of choices, making it easy to find a machine that meets your budget and needs.

How to choose the right power of fiber laser cutting machines for your business?

In the world of fiber laser cutting machines, power is more than just a simple number, it is directly related to your processing ability, productivity, and even the profitability of your business. Therefore, choosing the right power of laser cutting machines is crucial to the development of your business. So how do you choose the right power?

- Cutting power

The power of fiber laser cutting machines directly affects the cutting ability of the machine. Generally speaking, the higher the power, the greater the thickness the machine can cut and the faster the cutting speed. However, this does not mean that higher power is better. The higher the power of the stainless steel fiber laser cutting machine, the higher the price. Therefore, it is important to choose a machine that meets your cutting needs within your capabilities.

- Processing Requirements

Your processing needs are an important basis for choosing the power. Different metal materials and thicknesses require different laser power for efficient cutting. For example, cutting thicker aluminum requires a higher power aluminum laser cutting machine. 1500w laser cutting machine can satisfy your needs if you need to cut metal plate with a thickness up to 10mm; if you need to cut plate with a thickness of 10-20mm, fiber laser cutting machine If you need to cut metal sheets with a thickness of 10-20mm, fiber laser cutting machine 2000w is the right choice; if you often cut metal sheets with a thickness of 25-30mm, you can get your ideal machine at 3000w laser panel cutting machine factories.

- Budget Considerations

Your budget is an important factor that should not be overlooked. Maximize the benefits by choosing a fiber laser cutting machine that will meet your needs for both your house and for some time in the future, within your budget.

- Seek professional advice

If you are confused about how to choose the right power of fiber laser cutting machines, seek professional advice. They can recommend the most suitable equipment for you according to your specific needs and budget, and help you make a wise investment decision. In addition, if you have friends around you who have purchased laser cutting machines, you can seek more advice from them or visit the equipment on site, which will also help you make a reasonable decision.

Conclusion

Low power fiber laser cutting machines with their advantages in the laser cutting market occupy a place, for the majority of small and medium-sized metal processing enterprises and individual users to provide ideal processing solutions. With the continuous development of technology, the application prospect of fiber laser cutting machines will be broader, bringing changes and development for more industries.

If you are looking for a metal cutting machine that can meet your processing needs, improve productivity, and reduce costs, XTLASER professional laser cutting machine supplier is undoubtedly a choice worth considering. They have a professional technology development and after-sales team, so you can rest assured to buy.