How To Choose The Best Laser Marking Machine?

From electronic products, jewelry to automotive parts, medical equipment, laser marking for its wide range of applications by more and more individuals and enterprises. There are many types of laser marking machines on the market, and the quality of the machines varies, so how can you choose the most suitable equipment for your needs? In this article, we will discuss in depth the purchase of laser marking machine skills, to provide you with a comprehensive guide to help you find the best laser marking machine in a number of brands and models, to help your business development.

What is laser marking machine?

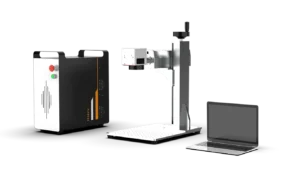

Laser marking machine is the use of laser beams on the surface of a variety of different substances, through the light energy to make the surface material to undergo physical or chemical changes, so as to carve out patterns, trademarks and text and other permanent marking equipment. Common laser marking machine: fiber laser marking machine, CO2 laser marking machine, UV laser marking machine.

The main configuration of the laser marking machine components include: laser, galvanometer, field mirror, marking card, industrial control computer, cabinet enclosure, scale and lifting axis.

What factors need to be considered when choosing a best laser marking machine?

The material of the product to be marked

Production enterprises in the selection of laser marking machine, first of all to consider the material of the product being processed, different materials, configuration parameters are different, such as metal marking and engraving generally use fiber laser marking equipment, non-metallic materials such as wood, leather, ceramics and other materials can be selected from the carbon dioxide laser marking equipment, plastics, silicone, acrylic and other fine materials such as marking, perforation is recommended to use the UV Laser marking equipment.

Machine configuration parameters

The main configuration parameters of the laser marking machine are: laser type, laser wavelength, laser power, marking range, engraving speed, etc., which marking range is determined by the field mirror, marking speed is also affected by the density of the product material, marking depth, marking width size and other factors.

- laser: it is the core component of the laser marking machine, its quality is one of the main factors affecting the marking effect, the well-known laser brands such as Maxphotonics, Raycus, JPT, etc., good quality, high stability.

- Laser power: in the case of determining the material of the processed product, the power should be selected to meet the processing requirements of the model, but do not blindly choose high-power.

- Field mirror: its role is to focus the light out of the galvanometer in a plane, the field mirror determines the marking range, the choice of laser marking machine, need to make clear the marking range of their own products, according to their own needs to determine, but also do not blindly seek large.

- Laser marking machine can be divided into two kinds of static and flight according to the mode of operation, products marked on the conveyor belt is recommended to choose flight laser marking machine, static secondary processing is used static laser marking machine. In addition, in general, the greater the laser power the more heat it generates, cooling mode should be based on the size of the heat to choose air-cooled or water-cooled.

Fiber laser marking machine brand

When purchasing laser marking, choose a larger or well-known company if possible. Excellent brand is not like a trademark can be obtained through the registration, it is through the baptism of fierce market competition, recognized by consumers as well as groups related to the company, trust, appreciation and the formation. Brands with strong strength can guarantee the quality of products and after-sales service.

After-sales guarantee

Laser marking machines are not disposable products. When purchasing a marking machine, make sure that the supplier can provide timely after-sales service. If the laser marking machine fails, timely after-sales service can reduce the downtime of the equipment and avoid excessive economic losses. In addition, it is inevitable to encounter operational or technical problems during the use of the equipment. Good after-sales service can provide professional technical guidance and training to help you better master the use of the machine.

Best Fiber Laser Marking Machines

Laser marking with what software?

Laser marking machine supporting software is mainly gold orange laser marking software EzCad, auxiliary software CorelDRAW, AutoCAD, Adobe Illustrator, photoshop. laser marking software support vector graphics format plt, dxf, ai, dst, if cdr, dwg and other formats material, you can use CDR If the material is in the format of cdr, dwg, etc., it can be converted into the format required by the marking software using CDR, CAD, etc.

Can laser marking machine engrave on sheet metal shell?

Sheet metal housings are thin sheet metal materials made of external protective structures, lightweight, beautiful, strong and so on, very suitable for electronic equipment, automotive industry, home appliances and household products, industrial equipment, fiber optic and instrumentation applications. Of course, these sheet metal shell in the process of processing needs to be used in the marking process, so there will be a lot of people want to know whether the laser marking machine can be in the sheet metal shell for fine engraving?

Sheet metal metal special laser marking machine is a set of laser, computer, automatic control, fine mechanical technology as one of the high-tech products. Then in the metal marking fiber laser marking machine has a 1064nm infrared laser beam, can be clear in the sheet metal shell of the surface layer of the marking, through the infrared beam in the sheet metal surface layer of the path of the burn traces left behind is known as the laser marking process.

Laser marking machine in the sheet metal shell on the fine engraving of the main problems faced by the laser energy control and engraving accuracy. However, laser energy control directly affects the depth and sharpness of the engraving. If the laser energy is too strong, it may lead to burning or deformation of the sheet metal casing; while too weak an energy may lead to unclear engraving or failure to achieve the required depth. In addition, engraving accuracy is also affected by the degree of focusing of the laser beam, the precision of the motion system and the roughness of the surface of the sheet metal housing.

Therefore, we want to carry out fine engraving on the sheet metal shell need to pay attention to related issues:

- Optimize the laser energy control, to find a better laser energy parameters to ensure that the depth and clarity of the engraving on the sheet metal shell are in line with the requirements of the mark.

- Improve the engraving accuracy. You can use a higher power laser to mark the surface of the sheet metal shell for fine marking.

- Encountered a rougher appearance of the sheet metal, you can first preheat its processing treatment before engraving.

So the laser marking machine in the sheet metal shell on the fine engraving is completely feasible, but in the operation of the project there are certain precautions. With the development and progress of science and technology, laser equipment on the sheet metal marking more and more mature, we look forward to its application in more industries together.