Laser Cutting Machine Tube: Your Partner for Customized Solutions

Accuracy and efficiency merged together presses escalate the production to the next height in the industry. But in terms of cutting metal pipes and tubes, it seems that raditional methods often fall short. That's when laser cutting machine tube technology comes in - with unmatched accuracy, speed and exceptional range of uses, these machines have indeed changed the way whole industries generate tubular components. This article takes a closer look at laser cutting machine tube, analyzing their functionalities, advantages, and top manufacturers and distributors of this technology. If you are in the auto, aircraft, construction or even furniture industry, understanding this technology can unlock new levels of productivity and innovation.

What is a laser cutting machine tube?

Otherwise known as tube laser cutting machine, a laser cutting machine tube is a type of Computer Numerical Control (CNC) machine tool which is specifically used to cut metal tubes by means of a powerful laser beam. Laser cutting has many benefits compared to the more conventional ways of cutting, including:

- Precision:The focused laser beam achieves incredibly precise cuts, ensuring intricate designs and tight tolerances.

- Versatility: Laser cutting machine tube for metal can process various materials, including stainless steel, aluminum, copper, and

- Speed:Laser cutting is significantly faster than traditional methods, boosting production rates.

- Flexibility:These machines can handle various tube shapes and sizes, from round and square to rectangular and even complex profiles.

- Clean Cuts:The laser beam creates a clean, smooth cut with minimal heat-affected zones, reducing post-processing needs.

Top 6 laser tube cutting machines in the world

There are lots of tube laser cutting manufacturers in the world and every manufacturer has tube laser cutting machines which have distinctive specifications, features, and functionalities. Here are the brand names along with their top models:

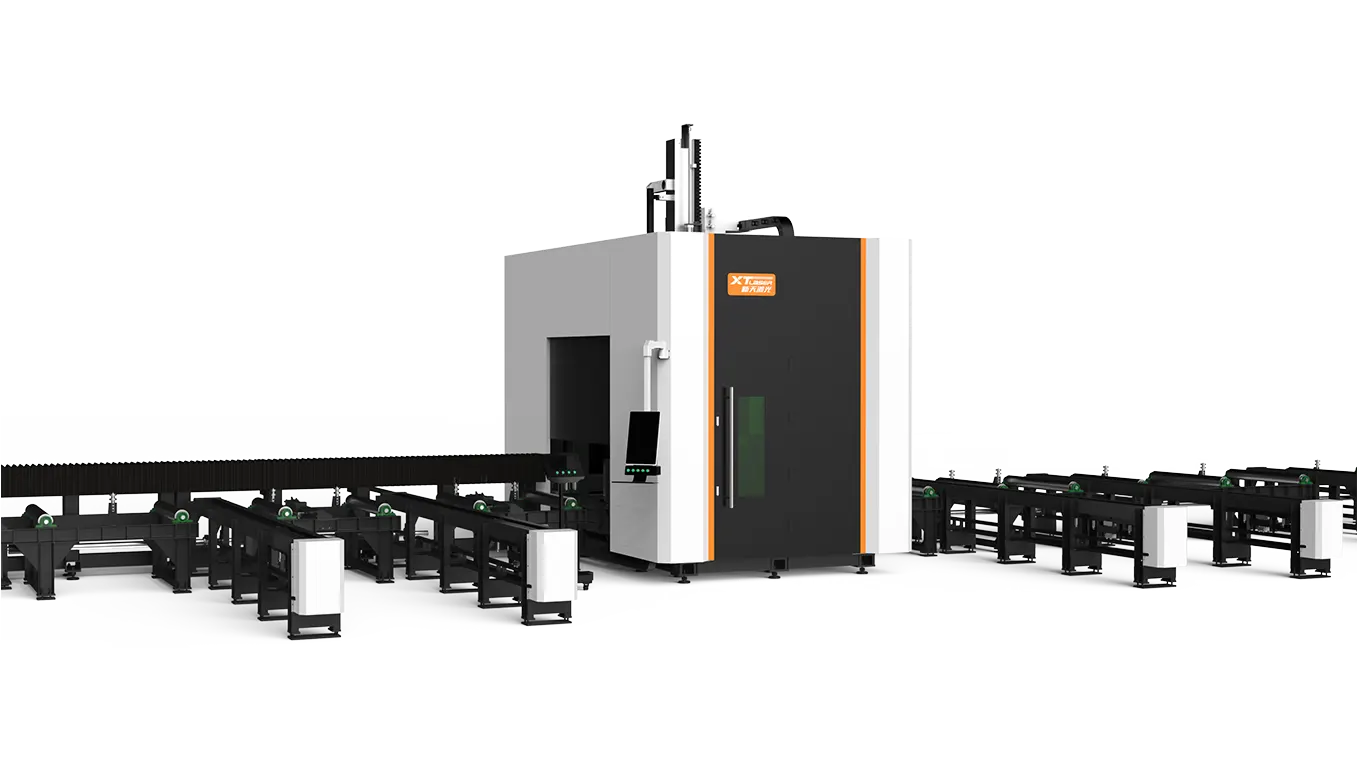

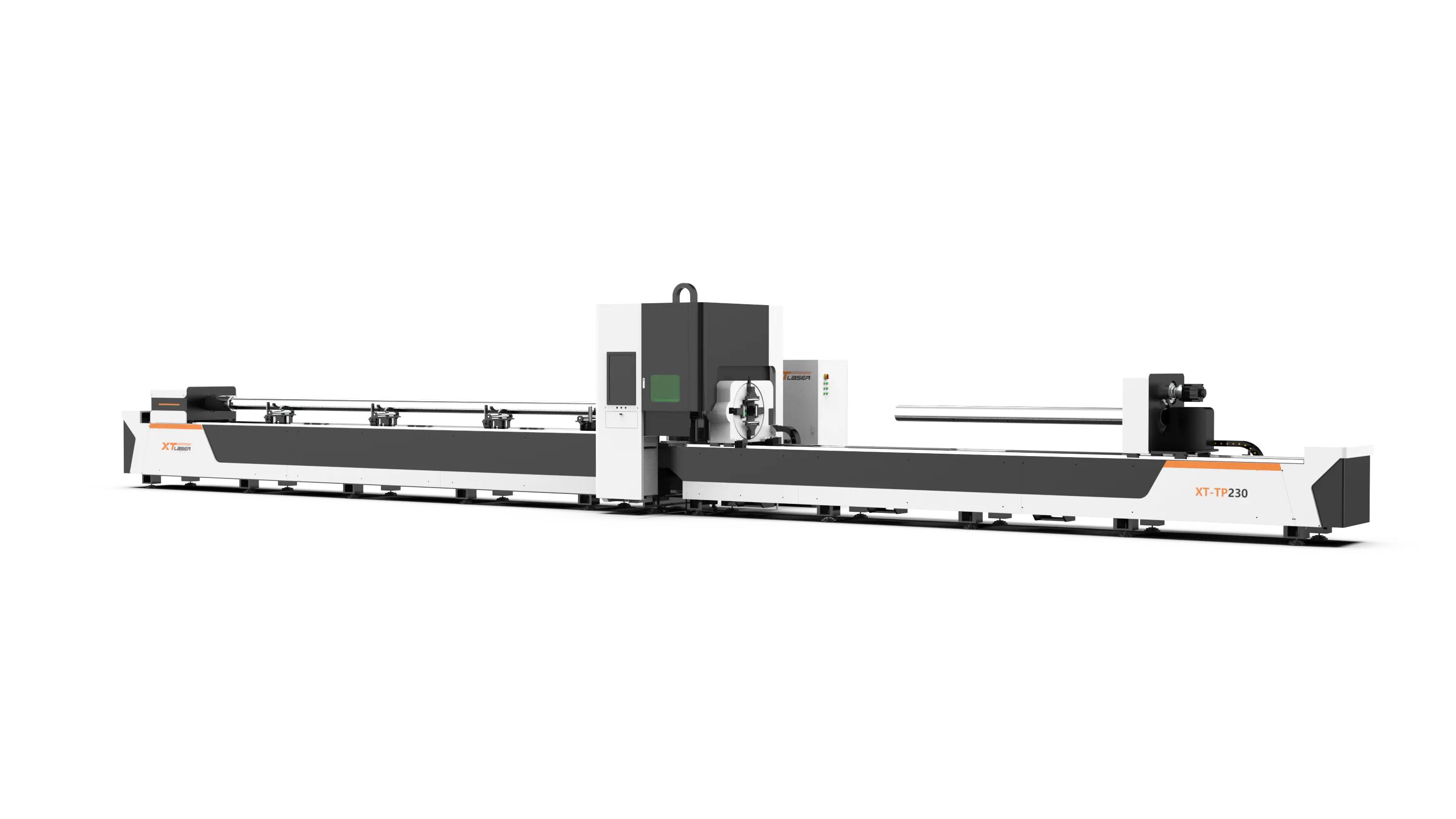

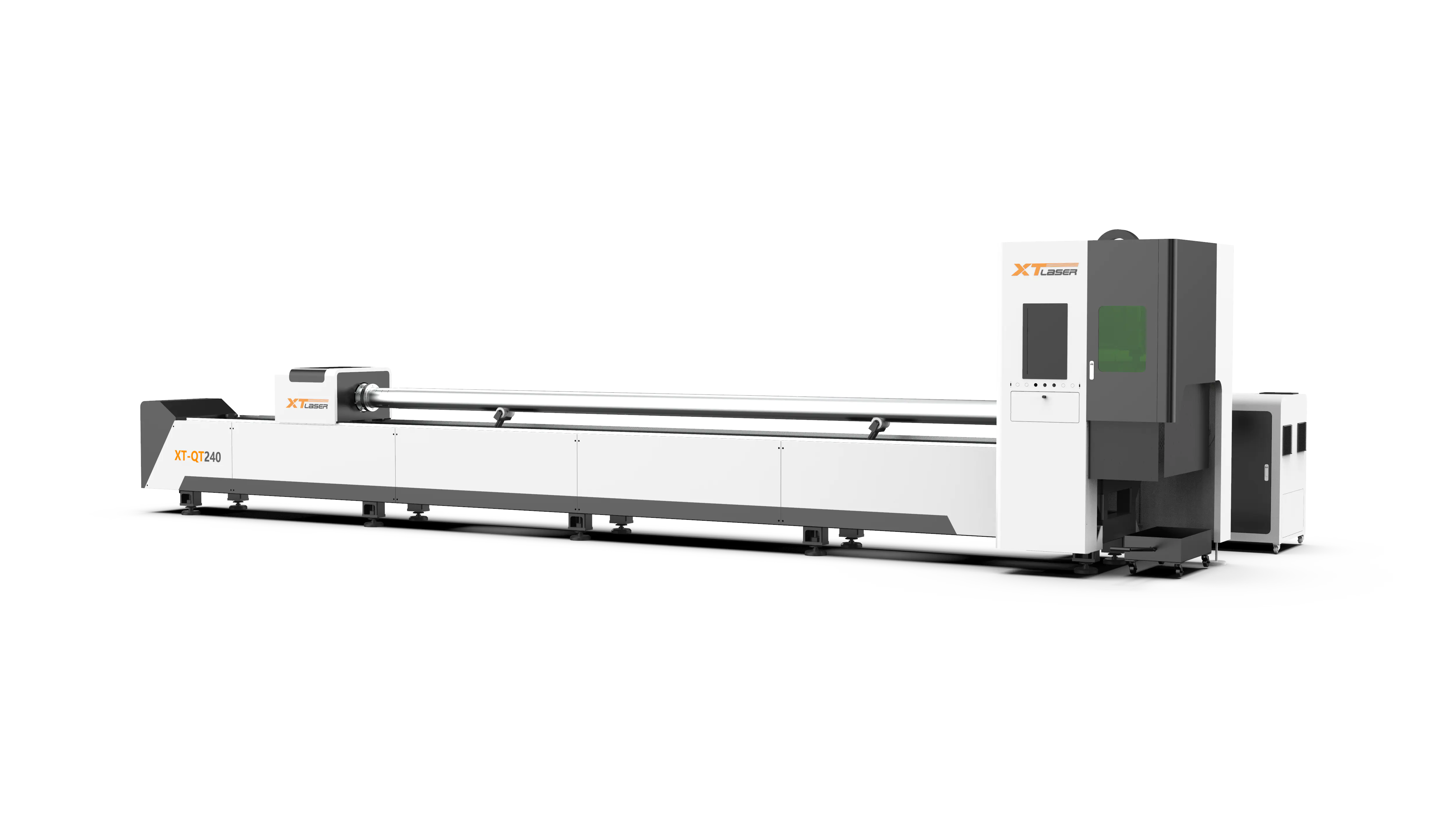

- XT LASER best tube laser cutting machine: The light cutting machines from XT LASER are all built with accuracy, cutting dependable and exceptional metal tube laser cutting machines. They are cost effective and fit a range of industries.

- TRUMPF has the best accurate cutting and there productivity is also flawless it is basically resulting in them being the leading hub of laser technology with the trumpf laser tube cutting machine.

- Bystronic tube laser: Their innovative and friendly interface, while equipped with automation, makes the laser tube cutting machines convenient for modern manufacturing methods.

- Amanda tube laser: Amanda specializes in economical laser tube cutting machine which are strong and able to meet different task applications.

- BLM tube laser cutting machine: The BLM Group specializes in 3D laser tube cutting machine and additionally they are capable of cutting complicated geometries with precision and accuracy.

- Bodor tube laser cutting machine: Bodor offers a variety of fiber laser cutting machine tube. Bodor provides various types of laser tube cutting machines, including automatic loading laser tube cutting machine, H steel laser cutting machine, etc.

It is important to note that selecting the right tube laser cutting machine largely depending on the needs of the customer, their price range, and anticipated use of the machine.

Laser cutting machine tube price

For a good number of customers, laser cutting machine tube price is a major concern. It’s not a one-size-fits-all situation, but knowing the basics can assist buyers in making better choices. Here is a breakdown of the key elements affecting the price of a product:

- Laser Power: This is a primary factor. More power will allow cutting at higher speed and cutting of thicker materials.

Price Range:

- 1kW – 3kW: Tube laser cutting machine price normally ranges between $15 000 and goes up to $30 000. Best for small and mid-sized companies to cut thinner tubes.

- 3kW – 6kW: Most of them are around $30 000 to $40 000. These laser tube cutting machines offer a good balance of power and price for most applications.

- 6kW and above: Prices can exceed $40,000 and go well beyond $60,000 for high-end systems. These are for heavy-duty applications requiring high throughput and the ability to cut very thick tubes.

- Brand Reputation: Established brands like Trumpf, Bystronic, and Amada often command a premium due to their:

- Proven track record of reliability

- Advanced technology and features

- Strong after-sales service and support

- Automated Devices: In most cases the automated features impact the price for devices.

- Basic Machines: Manual loading and unloading, simpler controls.

- Semi-Automated: Automatic tube loading, but manual unloading.

- Fully Automated: Automated loading, unloading, and material handling with robotic systems. This reduces labor costs but increases the initial investment.

- Cutting Capacity (Diameter and thickness of tubes):

Smaller Capacity: Machines specifically built for diameter thin tubes are more reasonably priced.

Larger Capacity: Machines that can accommodate larger diameter and thicker tubes come at a higher cost due to the robust construction and more powerful components required.

- Cutting Features:

Basic Level Cuts: Straight cut along with various simple angle cuts.

More Features: Cutting based on bevels, chamfering, complex angles, and cuts in three dimensions add to the cost.

- Warranty and After Sale Services:

Warranty Period: Longer warranties offer peace of mind but might come with a slightly higher price tag.

Service Packages: Comprehensive maintenance, on-site support, and readily available spare can effect the cost.

- Software and Control System:

- Basic CNC Controls: Utilization of standard functions and programs for operations.

- Advanced Software: For example, nesting software that ensures the best use of materials, simulation of the part in 3-d, CAD/CAM software, etc Can Also Raise The Cost.

Bear in Mind:

- Request detailed quotes: Don’t just concentrate on the initial price. Get quotes that include all the features, options, and services you need.

- Factor in long-term costs: Eg utility costs like electricity, gas (when applicable), maintenance.

- Assess your needs: Do not spend on a machine/cutting system that is not justified by your production needs. Try to consider the fiber laser cutting machine tube that is within your budget to avoid wastage of excess features that will remain unused.

Why choose XT LASER‘s laser cutting machine metal tube?

XT LASER differentiates itself from competition as it is one of the foremost companies in this industry when it comes to laser cutting machine metal tube because of the following reasons:

- Advanced Technology: With the use of laser cutting machine tube for metal, XT LASER guarantees fast, precise and efficient cutting.

- Wide Range of Models: They have a list of tube laser cutting machines for sale that will fit different needs and budgets.

- Customization Options: XT LASER optimized designs are available for a particular end use for maximum efficiency.

- Customization Options: XT LASER provides customized solutions tailored to specific applications, ensuring optimal performance for your unique requirements.

- Excellent After Sale Service: XT LASER will be providing out great support to clients that will cover tech support, training, and maintenance.

XT LASER Hot Selling Tube laser cutting machines

Conclusion

Laser cutting machine tube technology has revolutionized the way processing with metal tubes. Due to the thickness, speed, and overall versatility the laser cutting method stands the greatest chance of satisfying customer needs. If you are looking at increasing production output, decreasing cost of production, or bettering the quality of your products, the metal tube laser cutting machine is the answer.

When deciding on a machine, keep your requirements in mind and take a look at the machines produced by major manufacturers, such as XT LASER. Their commitment to innovation, quality, and customer support makes them a reliable partner for your laser cutting needs.

Q&A with laser cutting machine tube

A: Metal tube laser cutting machine has the potential to cut through a wide variety of metals such as, aluminum, copper, brass, galvanized steel, mild steel and stainless steel.

A: Laser cutting offers several advantages, including higher precision, faster cutting speeds, greater versatility, cleaner cuts, and reduced material waste.

A: It is important to consider factors such as what materials will be cut, what cut capacity is needed, a desired cutting budget, level of automation needed and what after sales support will be available.

A: Maintenance includes routine cleaning of optics, inspection of consumables such lenses and nozzles followed by their replacement, and lubrication of movable parts.