Laser Cutting Machine Metal: Things You Didn’t Know

Laser cutting has revolutionized the way we work with metal, offering unparalleled precision, speed, and versatility. This technology has turned out to be very useful in a variety of machines such as automobiles, aircraft, aerospace, and even in artworks. This article will unlock the complexities of laser cutting machine metal and its capabilities, including the types, applications, and advantages of laser-cutting technology.

What Is Laser Cutting Machine Metal?

Laser cutting machine metal sheet or plate can easily be cut with high degree of precision. A laser which could be a fiber laser or CO2, is equipped with an excitable beam that focuses very well. This energy focuses on the metal which results in melting or vaporization of the metal creating a very neat cut.

A typical China fiber laser cutting machine metal plate consists of several key components:

- Laser source: Generates the high-powered laser beam.

- Cutting head: Focuses and directs the laser beam onto the material.

- Motion system: Moves the cutting head or workpiece with precision.

- Control system: Operates the entire process, including laser power, cutting speed, and motion path.

Metal laser cutters for sale come in various sizes and configurations to cater to different needs and applications.

Types of Laser Cutting Machine Metal

Laser cutting machine metal can be broadly categorized based on several factors:

Power and cutting capacity: This shows the thickness and the kind of metal that this machine can cut. Industrial metal laser cutting machine possess high power, and are solely built for heavy duty jobs. Smaller machines for example, a small laser metal cutting machine are suited for thinner materials and complicated patterns.

Configuration: China cnc laser cutting machine metal usually has CNC (Computer Numerical Control) which allows automatic cutting that is based on the designs programmed.

Laser source: There is an upsurge in popularity of fiber laser cutters for metal because of its efficiency, accuracy, and cut capabilities on many types of metals.

XT LASER‘s range of laser cutting machines

A wide variety of metal laser cutting machine for sale which have been designed for different purposes have been manufactured by XT LASER. Here are some notable categories:

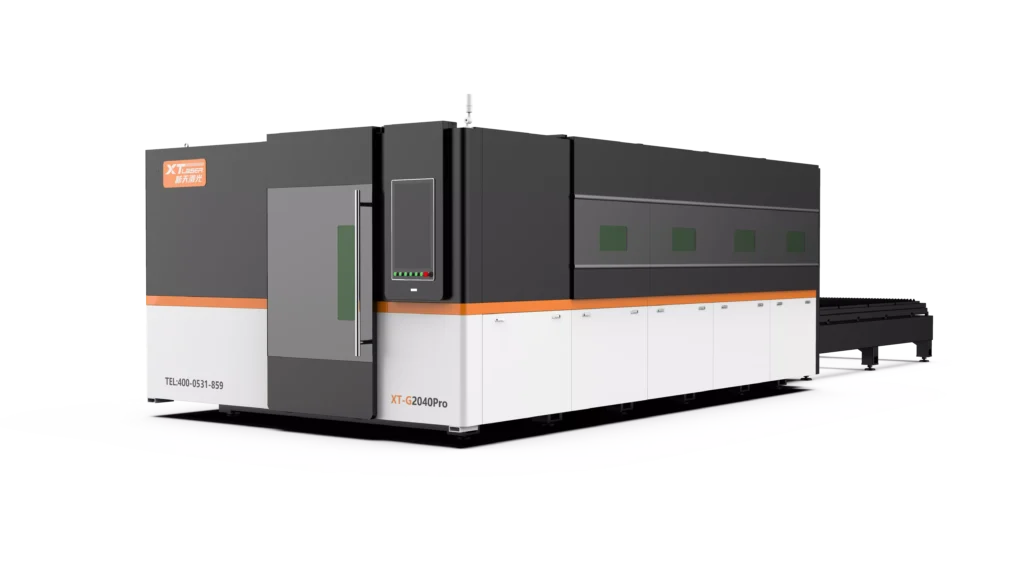

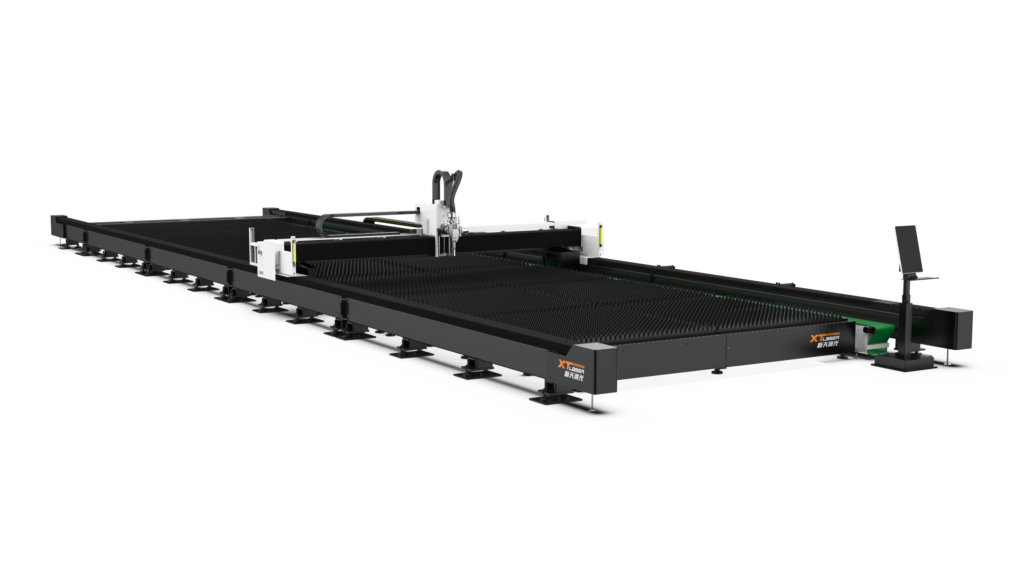

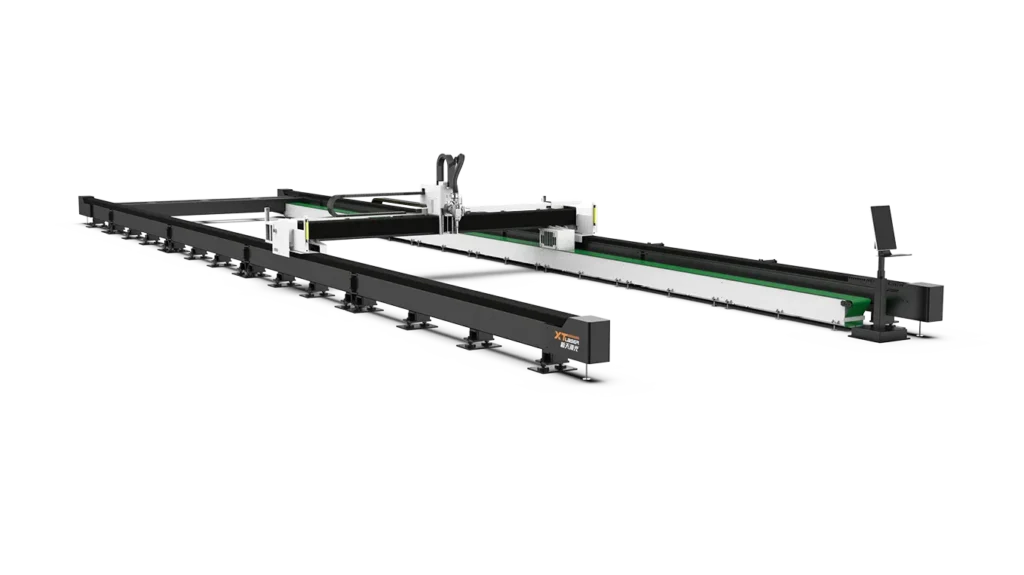

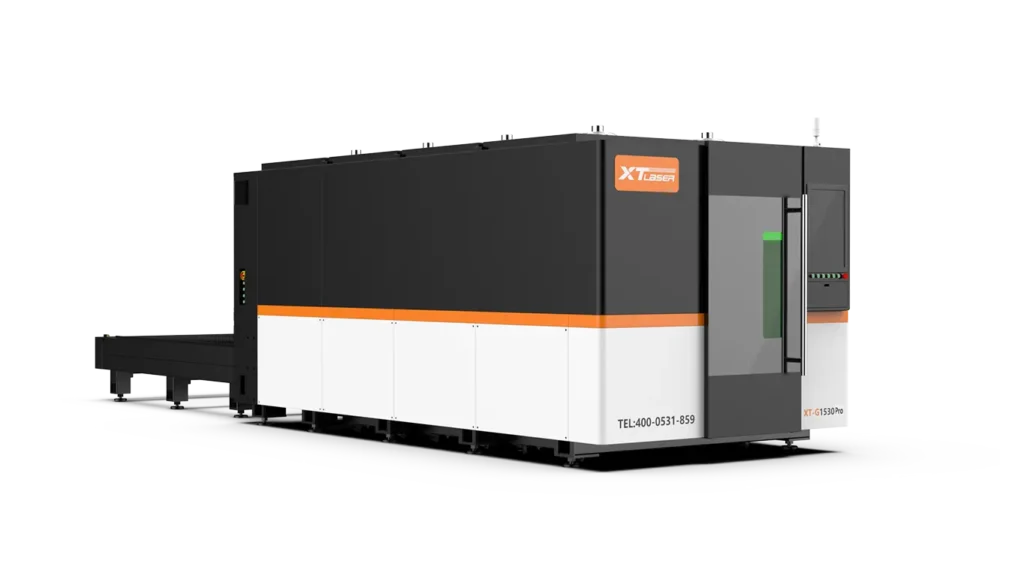

Industrial metal laser cutting machine: The industrial grade machines which are manufactured by XT LASER are meant for heavy duty jobs and provide high power along with large cutting area. These machines are ideal for industries like automotive, aerospace, and construction, where thick metal sheets and high-volume production are common.

High power laser cutting machine: XT LASER is an expert in providing high power fiber laser cutting machines that ensure good delivery speed and cutting accuracy. These machines cut through a range of metal thicknesses suitable for critical applications with high cut intricacy and high output.

CNC laser cutting machine metal: The CNC laser cutting machines from XT LASER allow advanced automation and high accuracy cutting. These machines have advanced control features which enable them to cut relatively complex shapes with complicated cutting paths. These are suitable for applications requiring extreme precision and reproducibility.

With the laser cutting machine metal for sale offered by XT LASER, the needs of different sectors and applications are well catered for. Their machines are targeted towards making their customers satisfied in terms of quality, performance, and reliability, hence they are ideal for any company that wants to improve its metal machining capabilities.

Applications of Laser Cutting Machine Metal

The versatility of laser cutting machine metal sheet is absolutely unquestionable; it finds applications in a host of industries:

- Automotive: Producing complex car parts, body panels and specific components.

- Aerospace: The manufacture of highly accurate parts for aircraft and space vehicles.

- Electronics: Cutting and shaping parts of electronic circuits and circuit boards.

- Medical: Making exact medical instruments as well as implants.

- Architecture and Construction: Constructing complex metal patterns to be used on the facade, interior and construction elements.

- Art and Design: Fabrication of highly specialized metal art, sculptures and decorative items.

Benefits Rendered by Laser Cutting Machine Metal

There are numerous benefits of professional laser cutting machine metal over older conventional methods even after taking into consideration the obstacles posed when transitioning to the new approach.

- Precision: There’s every design irrespective of its complexity that can be cut utilizing laser-cutting which is why the level of output is this satisfying.

- Speed: The process is significantly faster than traditional methods, increasing productivity.

- Versatility: Lasers can cut various types of metals and thicknesses with ease.

- Clean cuts: Edges cut using a laser cutter are smooth and clean without the need for any additional finishing processes to be employed.

- Automation: Manual cutting is both costly and liable to mistakes, however by using CNC technology most of these issues can be fixed.

Choosing the Right Metal Cutting Laser Machines

There are several considerations before one settles on a fiber laser cutter for metal for their needs and they include the following.

- Material type and thickness: It is vitally important to note that different laser powers are suitable for cutting different thicknesses of metals.

- Cutting speed and accuracy requirements: Your selection depends on the standards you require and the desired rate of production.

- Budget: Depending on the features and cutting capabilities of the machine, prices will drastically differ.

- Application: The specific application will dictate the necessary size and power of the machine.

If you are considering the cost, it is worth finding out and comparing the different prices. One might be curious to inquire how much are metal 8×4 cutting laser machines or how much for laser metal cutting machines 4×8. The price can vary based on the brand, laser power, features, and included accessories.

Metal laser cutting machine prices

The cost of a China laser cutting machine metal can vary significantly based on a multitude of factors. While it’s tempting to ask “how much is a laser metal cutting machine” and expect a straightforward answer, the reality is that pricing is influenced by a complex interplay of variables.

Factors influencing the cost

- Laser Power and Cutting capacity: It is usually the case; the more powerful types that can cut thicker materials and larger work areas are more costly. In the industrial setting, it is natural for a high power laser cutting machine to cost more than low power machines.

- Laser Source: The type of laser that is used has significant implications on the cost. For instance, fiber lasers might be more expensive as compared to CO2 lasers although they are more versatile. Also, the brand and quality of the laser source matter.

- CNC Control System: Innovative CNC control systems that include automatic nesting, path planning, and live monitoring also add to the machine costs. The price bracket is diversified by the level of sophistication and the functionalities that are embedded into the control systems.

- Cutting Head and Accessories: Different cutting heads are designed for specific materials and applications. Specialized cutting heads, automatic loading systems, and other accessories contribute to the final price.

- Machine Precision and Stability: High precision and stable machined items are constructed with better quality materials and construction, thus contributing to the overall price.

- Brand Reputation and Quality: Persistent brands which can be depended upon when it comes to the output, their functionality, and after the sale are usually expensive.

- Customization: Customizing a machine to meet specific requirements, such as unique cutting needs or specialized automation features, will influence the price.

Price Ranges

- Small Laser Metal Cutting Machine Price: Ideal for hobbyists or small businesses dealing with thinner materials, these machines can cost around $20,000 up to a few thousand dollars.

- Medium-Sized Laser Cutting Machines: These types of machines with more power and larger cutting areas usually cost between the range of $20,000 and $80,000.

- Large Industrial Laser Cutting Machines: Designed for heavy-duty applications and high-volume production, these machines can cost upwards of $80,000 to several hundred thousand dollars.

Obtaining A Quotation

To get a precise answer to questions like “how much are laser cutting machines for 8×4 metal” or “how much are laser metal cutting machines for 4×8,” it’s essential to request personalized quotes from manufacturers or suppliers. While approaching for a quote, ensure that you mention clearly and provide them with a comprehensive list of what you are looking for, such as the following:

- The type of metal you will be machining (stainless steel, aluminum, brass, etc.)

- The maximum thickness of the workpiece material

- The desired speed rate and accuracy in cutting

- Typical size of your workpieces

- Needs for specific attributes or specific level of automatisation

Given this information, you may get personalized quotations that will meet your expectation. Look for laser cutting machine supplier and weigh in comparison the pricing, quality and service offered.

Do bear in mind that the fiber laser cutting machine price and the overall laser cutting machine metal price is bound to various configurations and options that you will select. While taking your decision, try to take into account your existing and anticipated needs, limits of the budget and payback periods.

Conclusion

Laser cutting machine metal has made a positive impact in the world of metal fabrication, with its extreme accuracy, speed and flexibility. From a complex structure to mass production, laser cutting provides a cost-effective and efficient solution for various applications.

After you realize the kinds of laser cutting machines, their use and the factors that determine the cost, you are empowered to make decisions that are aimed at improving your metal fabrication operations. If you are seeking a trustworthy partner for your laser cutting needs, XT LASER is an excellent company, they will help you succeed by professional solutions.