Robot Fiber Laser Cleaning Machine

Model – Robot Fiber Laser Cleaning Machine

Brand – XTlaser

Laser Power – 200W, 300W, 500W Optional

Cleaning Depth – 10-100mm

Robot fiber laser cleaning machine is a fully automatic cleaning machine that can remove rust, impurities, and paint from the surface of metal and non-metal objects. Cost-effective and perfect after-sales service.

best laser cleaning machine for sale

The laser cleaner machine can be used for removing rust, paint, oil, and grease from the surface of objects as well as for cleaning weld seams. Compared with the traditional cleaning process, the laser cleaning machine is more efficient, environmentally friendly, non-polluting, has no damage to the substrate cleaning equipment, and is more efficient, and simple operation.

XTLASER specializes in the development and production of various types of laser cleaning, laser welding, laser marking, and laser cutting equipments. We are committed to providing customers with high-quality laser equipment and services, there are several factories and after-sales service networks at home and abroad, to create a 3-hour after-sales service circle.

fiber laser cleaning machine specifications

| Laser Power | 200W | 300W | 500W |

|---|---|---|---|

| Laser Wavelength | 1064±5nm | ||

| Scanning Width | 10-100mm | ||

| Fiber Core Diameter | 100μm | 100μm | 200μm |

| Laser Focusing | 160mm | ||

| Working Environment Humidity | ≤70% non-condensing | ||

| Cleaning Efficiency | 3m²/h | 4m²/h | 6m²/h |

| Cooling method | Water Cooling(Pure or distilled water) | ||

Automatic robot laser cleaning machine details

Multifunctional laser cleaning

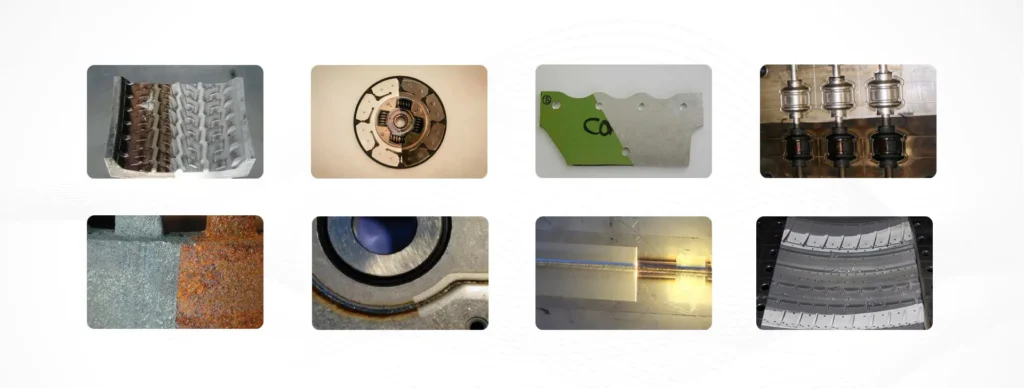

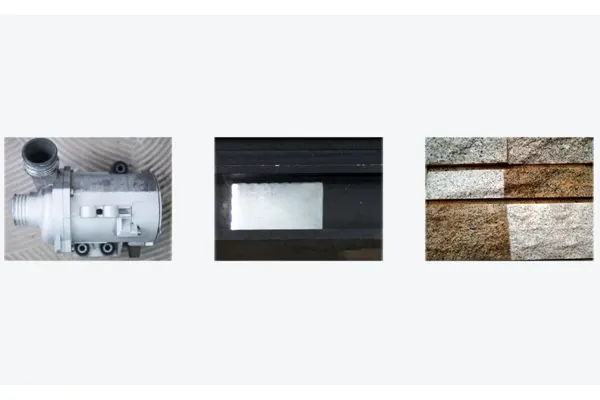

- Laser cleaning machines can remove rust, paint, coatings, oxidized layers, glue, etc. from metal surfaces.

- Non-metal surfaces such as stone, wood, sculpture, etc. can be cleaned.

Non-contact cleaning

- Pulsed laser cleaning machines and continuous laser cleaners use a focused laser beam to remove stains from surfaces without physical contact.

- The short duration of the laser impact does not cause thermal deformation of the surface and does not damage the substrate.

No environmental pollution

- The laser rust cleaning machine uses non-contact cleaning, does not use any chemical cleaning agents, and does not produce cleaning waste.

- Pollutant particles and gases generated during the cleaning process can be collected and processed by a small extractor fan, which will not bring pollution to the environment.

Low maintenance cost

- Laser cleaning machines in the use of the process do not use consumables, and machine running costs are low.

- During long-term use, only regular cleaning and replacement of lenses are required, resulting in low maintenance costs.

Fill out the form for professional support!

Why choose XTLASER's fiber laser cleaning machine?

The laser cleaning machine structure is simple, only by the electronic control cabinet, worktable, and 6-axis laser cleaning arm composition, adjust the parameters can be cleaned. Visualization of the cleaning process allows for timely detection and secondary cleaning of unclean parts.

Powerful automation and intelligent functions can realize efficient and stable operation and reduce manual intervention. Automatic positioning and automatic cleaning of stains can be realized by adding industrial lenses.

The automatic laser cleaner realizes contactless cleaning of oil, paint, and soot without cleaning agents or media. In addition, the machine has a long service life, which saves costs in the long run.

Compared to traditional cleaning methods, laser cleaning can effectively and quickly remove contaminants from the surface of objects. Thin paint layer cleaning can be done in one go without the need for secondary cleaning, saving time and labor costs.

Application areas of laser cleaners

Frequently Asked Questions

Factors affecting the price of fiber laser cleaning machine has a variety of factors, including laser power is an important factor in determining the performance and price of the cleaning machine, the higher the power cleaning efficiency, the larger the cleaning range is also larger, the price also increases accordingly, the same configuration of the machine, the price of 1000w laser cleaning machine and 100w laser cleaning machine price naturally some of the former high.

Laser cleaning machine of other configurations will also affect the price, such as different brands of cleaning head, control system, cooling system, etc., equipped with automatic cleaning head, intelligent control system, efficient cooling system of the laser cleaning machine price will be higher than the conventional to some.

Customized needs: some customers may have special needs, such as non-standard cleaning range, special cleaning head, add industrial lens, etc., the price will rise accordingly.

If you want to get the latest price information, you can contact XTLASER directly, you only need to provide your specific needs, and you can get a detailed quotation program.

Due to the adjustability of the laser parameters (e.g. wavelength, power, pulse width, etc.), robotic laser cleaning machines can not only clean metal materials but also a wide range of other materials, such as removing contaminants or coatings on plastic surfaces, cleaning dirt or grease on glass surfaces, removing oxidized or glazed surfaces on ceramic surfaces, cleaning contaminants or coatings on metal or composite surfaces, clearing stone or concrete surfaces of dirt, biological growths, etc.

It should be noted that although automatic laser cleaners can clean a wide range of materials when cleaning certain special materials or materials that you are not sure can be cleaned, you are advised to carefully assess their applicability or conduct a small area test to avoid irreversible damage.

To ensure safe and effective operation when operating the laser cleaner, you are advised to follow the following precautions:

1. Before the operation

The operator must have received professional training on the laser cleaning machine and wear personal protective equipment, including laser protective glasses, protective clothing, gloves, etc., to prevent radiation and fumes from the cleaning process from causing damage to the body.

Before use, check whether the parts of the laser cleaning machine are normal, whether the power supply is correctly connected, and whether the cooling system is working properly, and also keep the working area clean, dry, and well-ventilated.

2. During operation

Set the laser power, frequency, and scanning speed correctly according to the cleaning material to avoid excessive cleaning and damage to the substrate.

Strictly follow the operation manual, and keep a safe distance from the cleaning head and the cleaning area to avoid direct laser light on glasses or skin.

Familiarize yourself with the location and use of the emergency stop button of the laser cleaner to stop the operation of the equipment in time and reduce injuries in case of accidents.

3. After Operation

Clean the surface of the laser cleaner and the cleaning head to remove residues and debris.

Turn off the power of the laser cleaner and make sure the equipment is completely powered off before maintenance or moving.

XTLASER supplies a handheld laser cleaning machine, robot laser cleaning machine, and backpack fiber laser cleaning machine. How to choose different types of laser cleaning machines?

First of all, determine your needs.

What kind of material do you need to clean? Laser cleaning machines can clean metal, plastic, glass, ceramics, stone, and other materials. Make sure that the item you want to clean fits the purpose of the cleaning machine.

Are you buying a laser cleaner for home or industrial use?

If you need a small, portable laser cleaner for home use, it is recommended that you choose a handheld laser cleaner or a backpack laser cleaner; if you need to use it for industrial purposes, both handheld cleaner and robot laser cleaner are good choices.

Do you need manual or automatic cleaning?

Both handheld and backpack laser cleaning machines need you to operate manually, robot laser cleaning machines can be connected to industrial production lines to realize automatic cleaning.

Next, understand the key parameters of the laser cleaning machine.

- Laser power: the higher the power, the higher the cleaning efficiency and the higher the price. According to your cleaning needs to choose the right power, there is no need to pursue a high power cleaning machine.

- Scanning width: scanning width affects the degree of concentration of laser energy and cleaning effect, according to the cleaning depth and precision requirements to choose the appropriate scanning width.

- Cleaning efficiency: no need to use the power of the laser cleaning machine, cleaning efficiency is different. The higher the power, the larger the area that can be cleaned per hour.

Finally, multiple comparisons.

You can consult with multiple laser cleaner suppliers or friends who have purchased them to get their professional advice on purchasing.

You can also compare the performance and price of different brands and models of laser cleaners to choose your favorite equipment.

If conditions permit, you can go to the local manufacturers or agents to visit and experience the actual operation and cleaning effect of the equipment.

XTLASER always has a limited number of laser cleaners in stock. If you are ordering a standard model and it is in stock, it will be shipped within 7 days after you place your order. If you are ordering a non-standard customized machine or a model that is out of stock, it will take 15-30 days for us to manufacture and ship the machine.

If you have a clear purchasing plan, we suggest you order in advance to reserve enough time for production and transportation. After shipment, pay attention to the logistics information in time to know the status of goods transportation.

Related products

- Laser Cleaning Machine

Handheld Fiber Laser Cleaning Machine