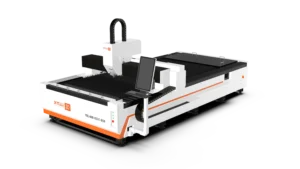

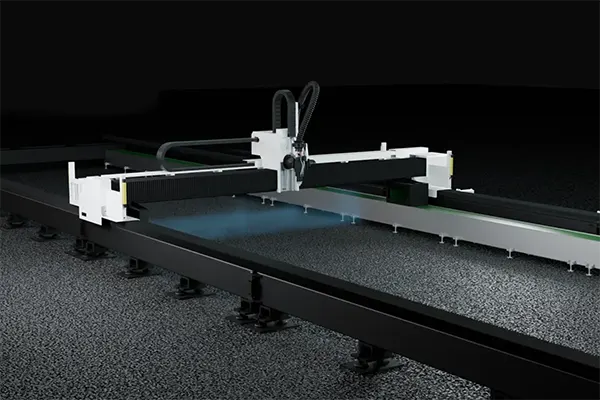

L Series Large Laser Metal Cutting Machine

Model – L Series Large Laser Metal Cutting Machine

Brand – XTlaser

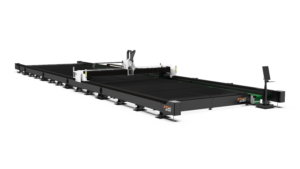

Processing Area – 3-5 meters wide, 12-50 meters long

Laser Power – 12000W-60000W are optional

The XTLASER large laser metal cutting machine features an extra-large processing format, a full steel structure bed, and a flexible transmission system, ensuring smooth and vibration-free cutting.

Laser Metal Cutting Machine for Sale

The large format high power laser cutting machine is designed to cut large metal sheets. The machine is equipped with a high-power laser and zoned dust removal, perfectly cutting metal workpieces while extracting smoke and dust during the processing, making it efficient and environmentally friendly.

As a professional fiber laser metal cutting machine manufacturer, XLASER provides the best laser cutting machines, laser marking machines, and laser welding machines to customers all over the world. If you are interested in laser equipment, you can contact our customer service staff anytime and anywhere.

fiber laser metal cutting machine Details

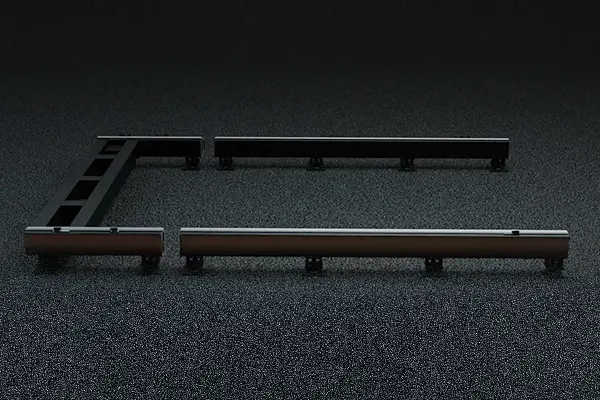

Segmented Stable Bed

- The bed adopts a segmented design, and the length can be freely selected according to processing needs. It can be infinitely extended to 50m according to the actual scene.

- The segmented design also solves the transportation problem caused by the machine exceeding the length and width of the container, saving time, effort, and money.

- The fiber laser sheet cutting machine adopts a high-strength steel structure bed, which can remain stable even under long-term high-intensity operation, ensuring cutting accuracy.

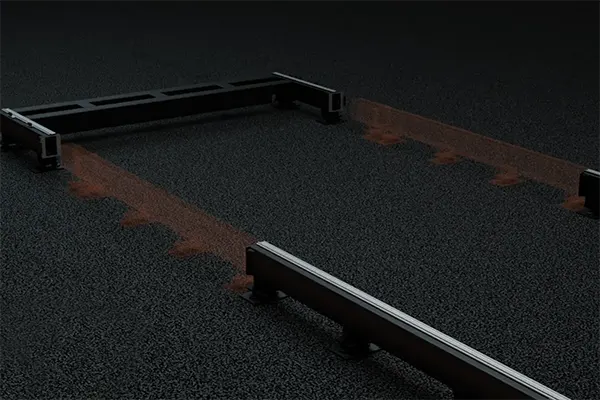

Flexible Transmission + Follow-up Extraction

- The flexible transmission system gives the machine excellent adaptability, easily coping with various complex cutting paths, and achieving 0-±45° bevel cutting at different angles.

- The follow-up dust extraction device of the fiber laser cutter moves with the beam.

- The axial flow fan blows the smoke and dust to the dust collection containers on both sides of the beam, reducing smoke and dust pollution and making the processing process more environmentally friendly.

Small Heat Affected Zone

- The bed is separated from the table to reduce thermal deformation during processing, ensuring cutting accuracy and workpiece quality.

- The table and the smoke extraction device can be optionally configured according to the thickness of the metal workpiece.

Largest Laser Cutting Machine

- The width of the fiber laser metal cutting machine can be 3-5 meters, and the maximum length can reach 50 meters, meeting your processing needs for oversized metal workpieces.

- The bed length can be infinitely extended to 50 meters in 4-meter units, providing infinite possibilities for metal laser cutting.

Contact Us

Fill out the form for professional support!

Why Choose XTLASER Heavy Duty Large Area Fiber Laser Cutting Machine?

The First Choice for Thick Plate Cutting

The large laser cutting machine is equipped with a high-power laser, which outputs high energy density and strong penetrating power and can easily cut plates of several centimeters or even thicker.

Diversified Cutting

Optional bevel laser cutting head to meet diversified cutting needs. In addition to metal sheets, large laser cutting machines also support the cutting of square tubes, one machine for multiple purposes.

Expandable Options

We provide customers with various expansion options, including processing tables, exhaust systems, beam protective covers, receiving platforms, industrial cameras, tool strips, etc. You can choose according to your needs.

Comprehensive After-sales Guarantee

XTLASER provides a comprehensive after-sales guarantee for industrial metal laser cutting machines, from training and installation videos to online technical support and on-site technical support. As long as you need it, we will provide it.

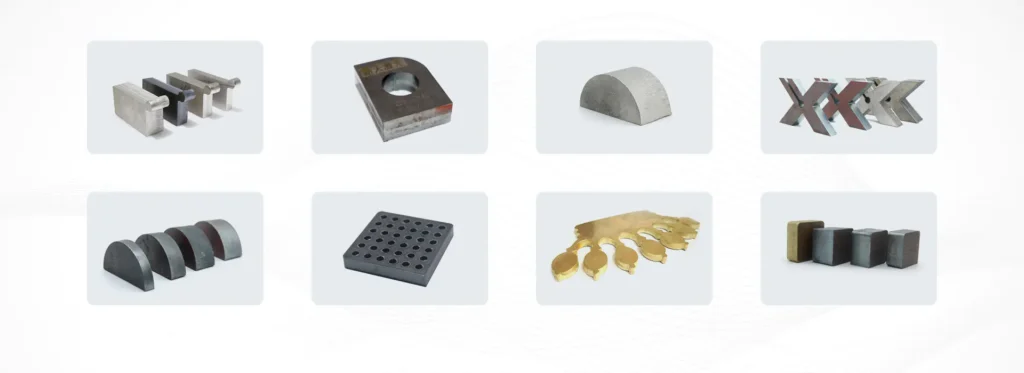

Applications of fiber laser cutterApplications of fiber laser cutter

Frequently Asked Questions

The thickness of the metal that can be cut by a laser metal cutting machine depends on the power of the laser. Generally speaking, the higher the power of the laser, the thicker the metal material can be cut.

XTLASER is specially made for thick plate cutting. The 12000W laser can cut 40mm thick carbon steel and aluminum plates, 50mm thick stainless steel, and 30mm thick copper. Higher power laser cutting has higher cutting capabilities and can cut thicker metal plates.

If you need a laser cutting machine for thin sheet metals, XTLASER's medium-power laser cutting machine can meet your choice. If you want to know more, please contact our customer service staff, and they will arrange for professional technicians to answer your questions.

The power selection of the laser metal cutting machine depends on the cutting thickness of the metal plate. If the thick plate is mainly cut for a long time, it is recommended that you choose a high-power laser cutting machine, such as the XTLASER GP series laser cutter, which can help you achieve the cutting needs of conventional size and thick metal plates.

If you need to cut large-size thick plates, such as cutting 3000 mm*12000 mm, 50mm thick metal plates, the L series large format high power laser cutting machine is the best choice.

If you don't know laser cutting machines and don't know which equipment to choose, it is recommended that you contact XTLASER's manual customer service. They will respond to your questions in the shortest possible time to ensure that you can get accurate answers.

Although laser cutting machines are widely used, it does not mean that they can cut all materials. As we all know, fiber laser cutting machines can cut most metal materials, such as steel, stainless steel, iron, galvanized iron, etc.

But it is not omnipotent after all. Laser cutting machines cannot process non-metallic materials, such as stone, cloth, leather, plastic, etc. In addition, since the fiber laser cutting machine belongs to thermal processing, it cannot cut density boards, wood, etc.

In addition, there are some common high-reflection materials, and to some extent, laser cutting machines cannot cut, such as aluminum, copper, etc. This is because the wavelength effect of high-reflection materials absorbing lasers is not ideal, and the reflected part of the energy will burn the protective lens and even cause great damage to the laser, so high-reflection materials cannot be cut for a long time.

In this case, why do many companies claim that laser cutting machines can cut high-reflection materials? This is because adding inert and auxiliary gas or choosing a laser with an anti-high reflection function can cut high-reflection materials when cutting high-reflection materials.

According to different classification methods, laser cutting machines can be divided into many types. If you want to cut metal, fiber laser cutting machine is the most suitable and effective way. This is mainly due to the following characteristics of the fiber laser cutter:

The structure is compact, the operation is convenient, the use is reliable, and the disassembly is convenient. As long as there is a place for wind and rain protection, it can be installed and used.

The photoelectric conversion rate of industrial metal laser cutting machine is higher, which saves more electricity than traditional metal cutting methods.

The application range of laser cutters is relatively wide, and any plane design pattern can be processed. It can cut laser size metal sheets without opening molds. It can cut various metal materials such as carbon steel, stainless steel, aluminum alloy, brass, red copper, titanium alloy, etc.

The laser cutting machine has high cutting accuracy and is controlled by cutting software. Just import the drawing of the cutting graphic into the computer equipment to realize the automatic path and cut it by itself. In addition, the high-precision cutting method reduces the cutting scrap rate and saves costs.

Generally speaking, the efficiency of fiber laser cutting machines is much higher than that of various mechanical physical processing equipment, which greatly shortens the time for processing metal materials and reduces labor costs.

After comparing different metal laser cutting machine suppliers, many customers found that the prices of metal laser cutting machines from various manufacturers vary greatly. The price of a cheap laser cutting machine may be less than 20,000 US dollars, and the price of an expensive laser cutting machine may be more than 200,000 US dollars.

Many factors affect the price of laser metal cutting machines. In general, the brand of the laser cutting machine, the processing size of the machine, and the brand of the laser will all affect the final price.

When purchasing a metal laser cutting machine, you must first clarify your needs, and then choose the type of laser cutting machine after analyzing the requirements and thickness of the cutting process. It is recommended to refer to and compare more when purchasing a laser cutting machine to find the right equipment for you.

Related Products

Related products

- Laser Cutting Machine

XT LASER 4000w fiber laser cutting machine for sale

- Laser Cutting Machine

XT LASER 6000w fiber laser cutting machine for metal

- High Power Laser Cutting Machine

L-series Ultra Large Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

E-series Open Type Exchange Table Fiber Laser Cutting Machine