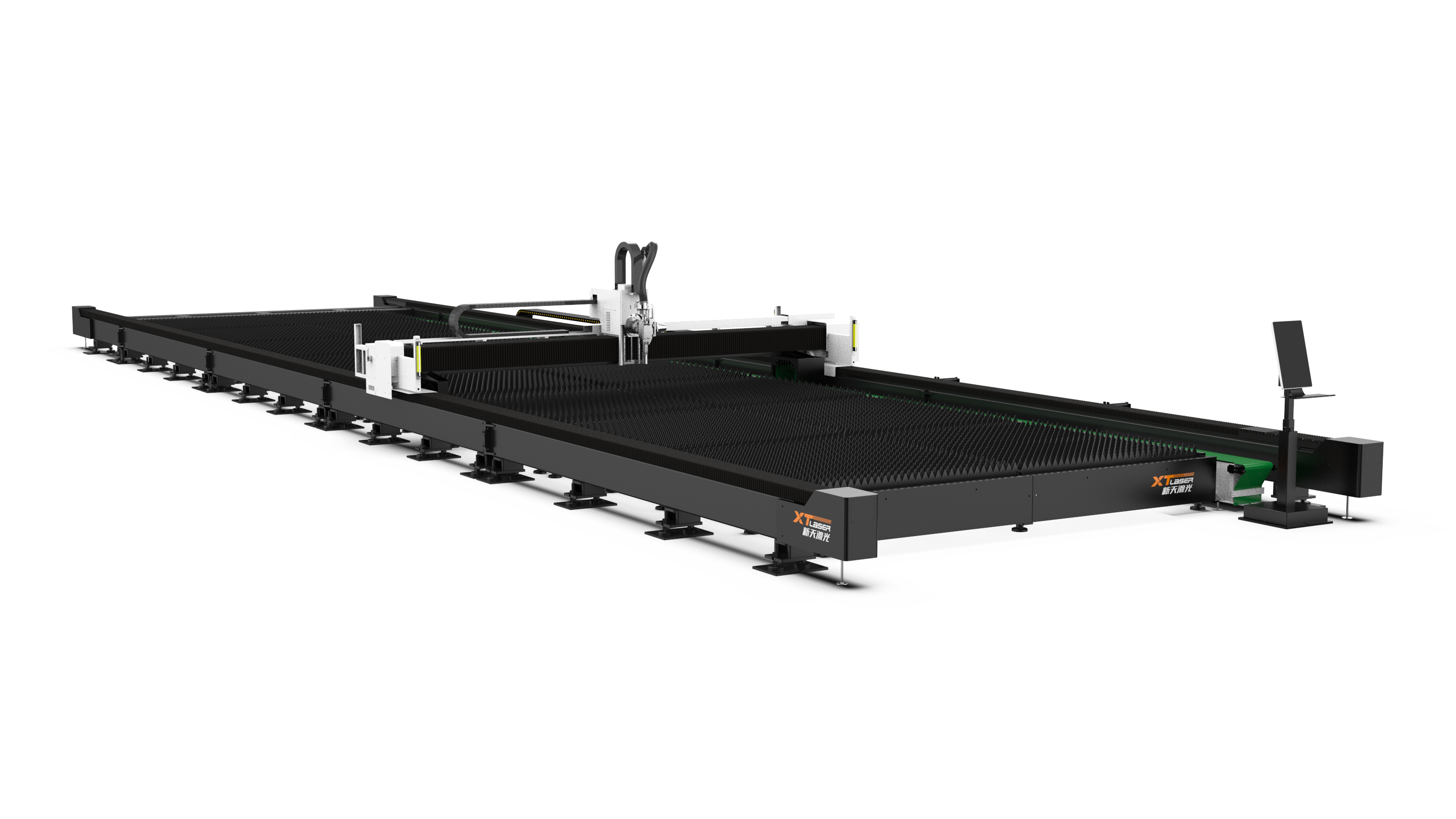

XTlaser is a supplier of laser processing equipment. L-series Ultra Large Laser Cutting Machine can cut metal materials including stainless steel, silicon steel sheet, aluminum, brass, copper, etc. with high precision and high efficiency, which can meet the diversified needs of the global market for large metal sheet cutting.

XTlaser-Customizable Laser Cutting Machine Manufacturer in China

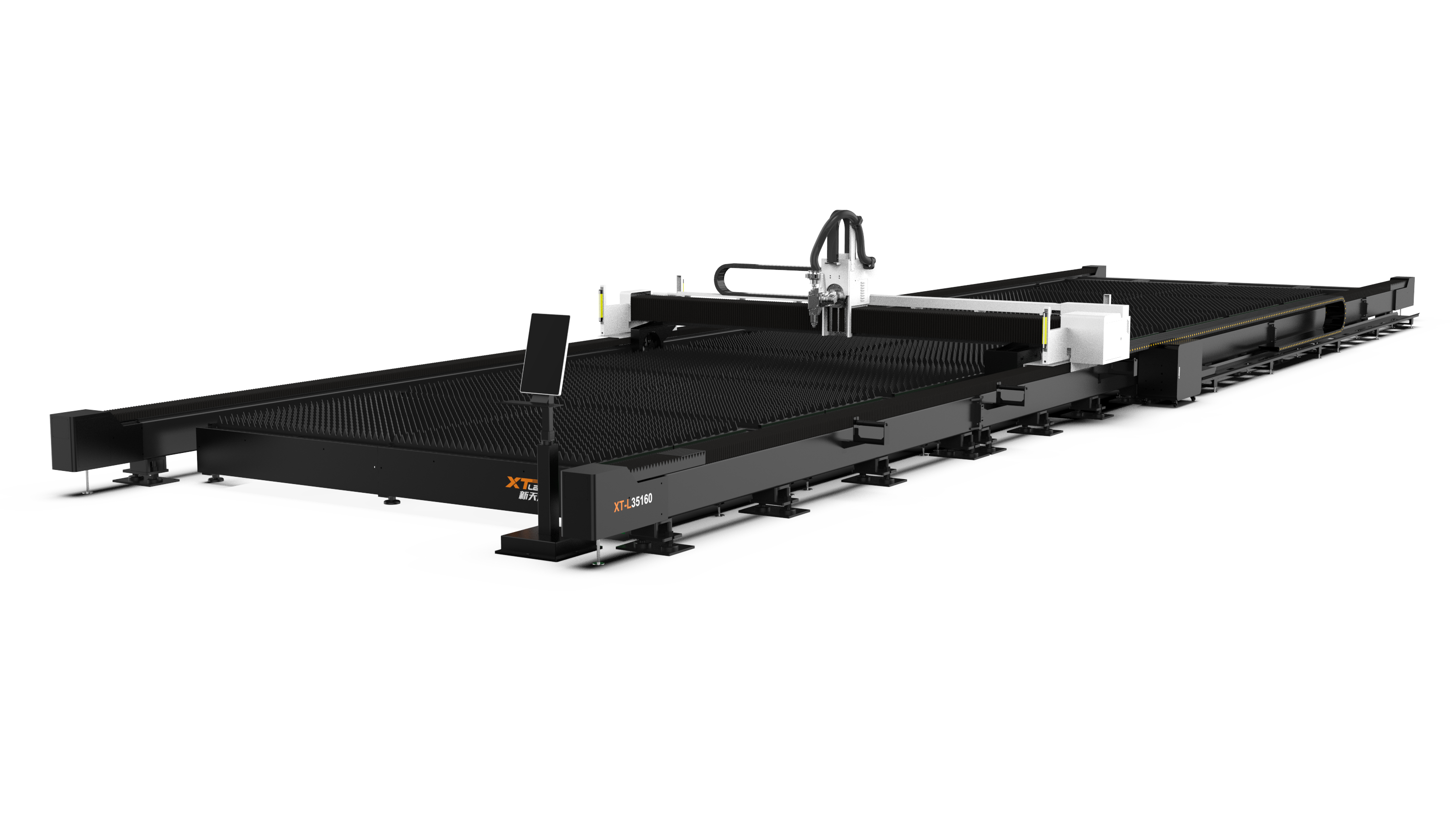

L-series Ultra Large Laser Cutting Machine Specifications

| Machine Model | XT-L20120 | XT-L30160 | XT-L30240 |

|---|---|---|---|

| Working Area(mm) | 3000*12000 mm | 3000*16000 mm | 3000*24000 mm |

| Laser Power(W) | 12000W-60000W | ||

| Linkage Speed | 50m/min | ||

| Acceleration | 0.5G | ||

| Processing Materials | Carbon steel, stainless steel, silicon steel sheet, galvanized sheet, aluminum, brass, copper, gold, silver, etc. | ||

L-series Ultra Large Laser Cutting Machine Features

- Ultra Wide Format XTlaser's L-series fiber laser cutting machines are equipped with an extra-long and extra-wide processing area to cut large metal sheets. For cutting small-sized sheets, the ultra large laser cutter can cut multiple sheets at one time, eliminating the need for frequent loading and unloading, saving time, and increasing efficiency.

- Zoned Air Extraction The L-series has front and rear-zoned air extraction, which can be switched on and off according to actual needs. The suction power is very strong, which can smoothly suck away the smoke and exhaust fumes during the process.

- High-power Laser XTlaser large laser cutter is equipped with a 12,000W-60,000W high-power laser, which can realize precise cutting of metal materials in large format and thick plates. Faster cutting speed and higher efficiency.

- Bevel Cutting This machine can realize bevel cutting of flat surfaces up to 45°, and one-time forming of different types of bevels, such as V, X, and Y, to improve the efficiency of sheet metal processing.

More About Large Format Fiber Laser Cutting Machine Details

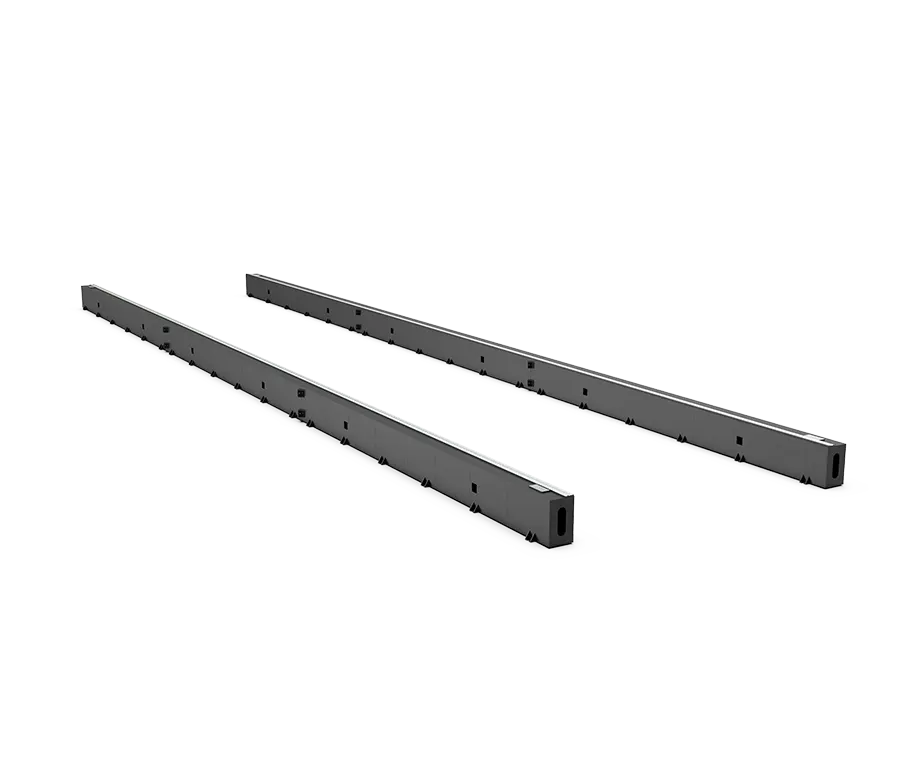

Butt Plate Welding Bed

Safety Light Curtain

Tube Welded Beam

Auto-focus Laser Cutting Head

Contact Us

Contact us for professional support.

Why Choose XTlaser’s Laser Cutting Machine?

As a leading brand of laser processing equipment, XTlaser stands out among many laser cutting machine suppliers with its excellent technical strength and professional service level.

Machine Selection Guide

XTlaser always focuses on customers' needs and provides professional machine selection guidance services. The pre-sales staff will tailor the most suitable laser cutting models for customers according to their specific needs and application scenarios, ensuring that customers can select the most suitable production equipment to maximize efficiency.

7*24 Year-round

XTlaser is well aware of the time difference between customers in different countries and us, and our technicians implement a shift duty system to ensure that we can provide customers with round-the-clock support services throughout the year. No matter when or where you are, you can always contact professional technicians and get timely solutions.

Perfect Service System

XTlaser not only provides one-stop laser equipment solutions but also provides a perfect service system. From pre-sales inquiry, obtaining quotations to placing orders, delivery, and after-sales, every step of the process is accompanied by our staff to solve any of your doubts. Therefore, you can choose XTlaser with confidence.

Two Years Warranty

We offer a two-year warranty on all our fiber laser cutting machines to fully guarantee the quality and performance of the equipment. During the warranty period, if the equipment has any quality problems, we will provide free repair and replacement services.

Application Areas of L-series Ultra Large Laser Cutting Machine

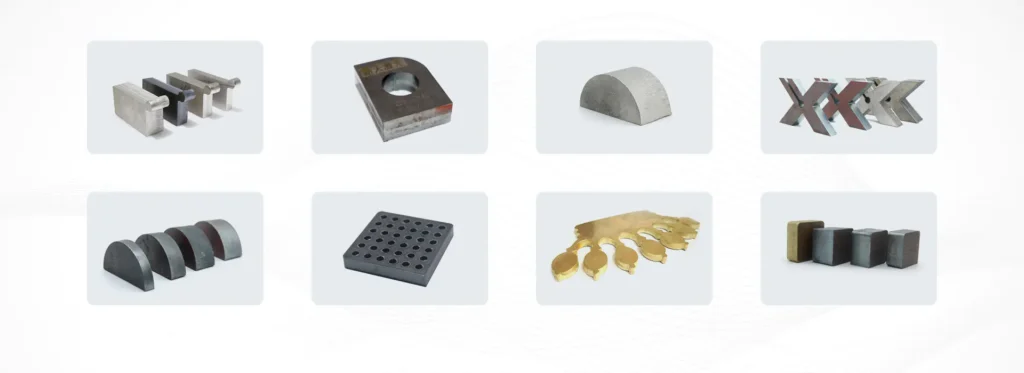

Laser Cutting Machine Samples for Metal

Here are some samples of cuts made by the fiber laser cutting machine.

Frequently Asked Questions

Usually, we finish the shipment within 30 days after receiving the order from the customer. In the case of customized laser cutting machines, the delivery will be completed within 60 days.

To ensure the quality of the laser cutting machine, XTlaser has taken a series of measures to guarantee the quality of the laser cutting machine.

High-quality components such as plate welded beds, welded beams, branded drive components, lasers, laser heads, etc. are used to ensure compliance with relevant quality standards and specifications.

In the process of machine manufacturing, we strictly implement the production process and use precision instruments to implement multi-channel precision testing, including raw material inspection, parts inspection, assembly inspection, function testing, etc., to ensure that the quality of each machine is stable and reliable.

We provide perfect after-sales service systems, including equipment installation, training, remote maintenance, spare parts supply, etc., to ensure that customers get timely and effective support in the process of using.

For small machine faults, we will arrange for technicians to assist you remotely to solve your problems in the shortest possible time and ensure the fastest possible resumption of production. For major machine breakdowns, we will arrange on-site assistance from our after-sales staff to solve your machine problems completely.

Related Products

Related products

- Laser Cutting Machine

KF-series Four-head Laser Cutting Machine

- High Power Laser Cutting Machine

W-series Ultra Large Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

H-series Open Type Fiber Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

G-series Fully Enclosed Exchange Table Fiber Laser Cutting Machine