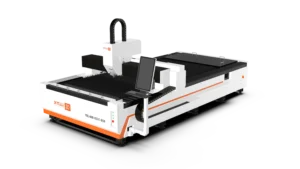

GP1530X High Speed Laser Cutting Machine

Model – GP1530X High Speed Laser Cutting Machine

Brand – XTlaser

Processing Size – 1550*3050mm

Acceleration – 2.8G

Laser Power – 12000W

The fastest metal laser cutting machine has extraordinary acceleration capabilities, with acceleration up to 2.8G, and can cut stainless steel, carbon steel, copper, aluminum, iron, and other metals at high speed.

China laser cutting machine factory

XTLASER is an enterprise integrating laser equipment research and development, production, and sales. It has complete research and development and manufacturing capabilities and is a powerful CNC fiber laser cutting machine supplier in China.

After 20 years of development, XTLASER has become a provider of intelligent manufacturing system solutions integrating laser cutters, tube laser cutting machines, CNC bending machines, automation, and other equipment.

High Speed laser cutting machine specifications

| Model | XT-GP1530X |

| Working Area | 1550×3050mm |

| Max Linkage Speed | 180m/min |

| Maximum Acceleration | 2.8G |

| Positional Accuracy | ±0.05mm |

| Repositional Accuracy | ±0.03mm |

| Adapted Power | 12000W |

Laser cut sheet metal machine details

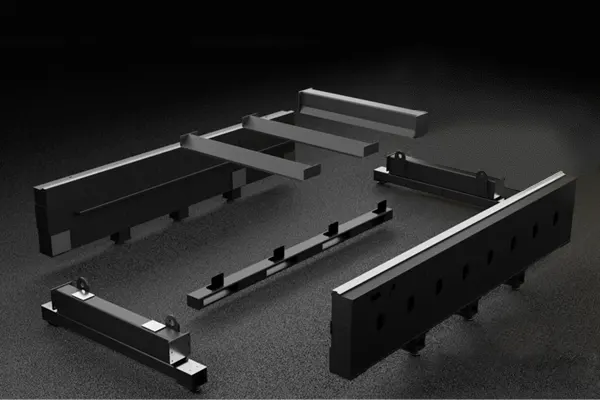

Split bed

- The ladder-type multi-stage lateral support has a high load-bearing capacity, and the processing process does not shake, ensuring cutting accuracy.

- The bed can be split, saving space, and easily solving the problems of difficult delivery and high freight caused by the oversized bed.

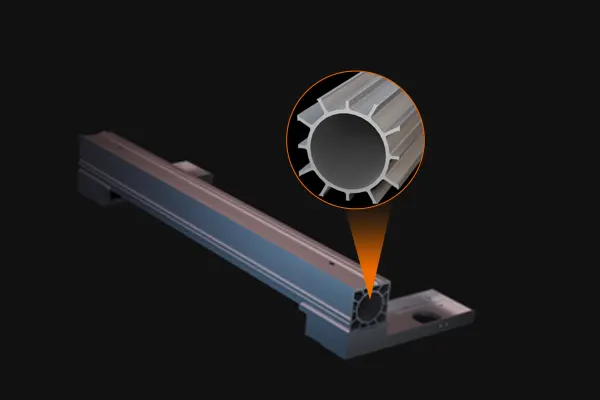

Aviation aluminum crossbeam

- The aluminum crossbeam manufactured according to aerospace standards has high hardness, is lightweight, and has good toughness and ductility.

- The aluminum crossbeam adopts a sunflower cross-section structure, which is very stable has strong compression resistance, and can maintain its shape to the greatest extent.

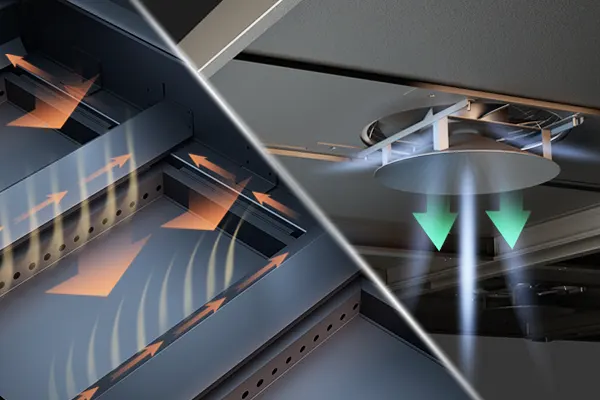

Up-blowing and down-pressing system

- A dust removal pressurization system is set up on the top of the machine. During the cutting process, the system blows air downward, increasing the downward air pressure, and assisting in enhancing the dust removal effect.

- Multiple rows of dust extraction areas are set horizontally on the table, increasing the dust extraction area, and the smoke and dust on both sides and in the middle can be instantly extracted, avoiding dust removal and dead corners.

- Set up multiple areas for dust removal in the front, middle, and back, and you can turn on some or all areas of dust removal as needed, saving resource utilization.

Human-machine interaction interface

- The position and height of the interactive display screen are designed with full consideration of human eye height and elbow height dimensions, allowing you to operate the laser cut sheet metal machine more comfortably.

- Set safety protection and red light alarm indication for the machine door, and automatically cut off the power when the door is opened to protect the personal safety of the operator.

Lifting table

- The metal cutting laser machine is equipped with a double-layer lifting table, which can be lifted alternately to save loading and unloading time.

- The table height is unified, and there is no need for repeated positioning. After the table exchange is completed, you can directly enter the processing area, improving processing efficiency.

Contact Us

Fill out the form for professional support!

Why choose XTLASER high speed laser cutting machine?

High-configuration

XTLASER adopts the world's top, stable output laser, cutting head, and numerical control system. High-quality parts not only ensure the stable operation of the optical fiber laser cutting machine but also greatly extend the service life.

Experienced team

We have an experienced R&D, production, and after-sales team. Each team member performs their duties to escort the quality of laser cutting equipment.

Advanced assembly technology

To ensure that the assembly accuracy of each laser cut sheet metal machine reaches the micron level, XTLASER's advanced assembly technology and precise quality inspection system run through the entire production process, ensuring consistent machine quality.

Comprehensive after-sales guarantee

From installation and debugging, operation training, and technical support to maintenance, no matter where you are, as long as you need it, we will provide you with a professional solution as soon as possible.

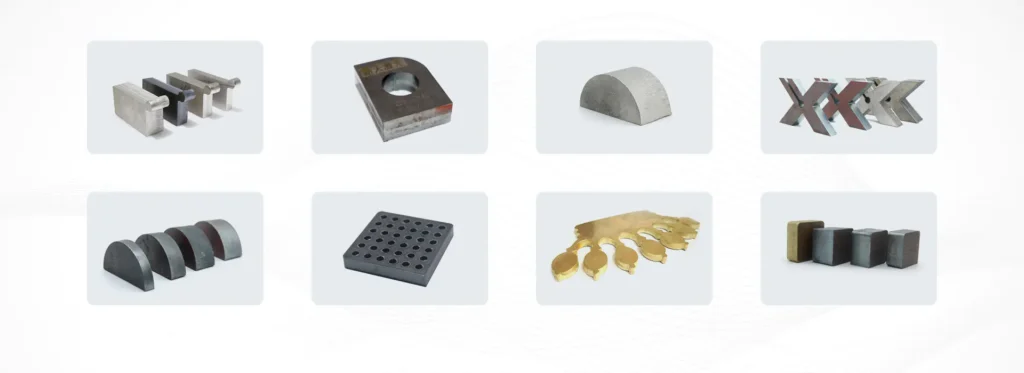

metal laser cutting machine applications

Frequently Asked Questions

The flexible metal processing characteristics of laser cutting machines are recognized by many sheet metal customers, and their cutting speed has a great advantage compared with traditional processing equipment.

Many factors affect the cutting speed of optical fiber laser cutting machines. Different processing materials, material thicknesses, and output power will affect the final cutting speed.

Assuming the maximum cutting speed of a 20000W laser cutting machine cutting 1mm thick of different materials: the maximum cutting speed of carbon steel is 85m/min; the maximum cutting speed of stainless steel is 100m/min; the maximum cutting speed of aluminum is 65m/min; the maximum cutting speed of copper is 85m/min.

In addition, the machine parameter setting is also one of the main reasons affecting the cutting speed of the 12KW laser cutting machine. Generally speaking, if the parameters are not adjusted properly, the cutting speed is not ideal. When adjusting the cutting speed parameters, you need to pay attention to the initial speed and acceleration.

Don't think that the higher the initial speed, the better! If the initial speed of the laser cut sheet metal machine is set too high, the machine will shake greatly.

Acceleration is the time it takes for the machine to go from initial speed to normal cutting. The laser cutter is a process of continuous starting and stopping when cutting different patterns. If the acceleration setting is too low, the cutting speed of the machine will slow down.

If you don't know how to adjust the machine parameters to the ideal state, you can search for solutions on Google or ask XTLASER's professional technicians for help.

XTLASER's fastest laser cutting machine is equipped with a 12000W laser and 2.8G acceleration, effectively ensuring the best cutting quality and efficiency.

The maximum cutting speed of a 12KW laser cutting machine cutting 1mm thick of different materials: the maximum cutting speed of carbon steel is 75m/min; the maximum cutting speed of stainless steel is 72m/min; the maximum cutting speed of aluminum is 85m/min; the maximum cutting speed of copper is 60m/min.

The above cutting speeds may deviate due to laser differences, cutting gas, optical lenses, metal material quality, cutting graphics, etc., and need to be adjusted according to on-site adjustments.

Some people who are interested in laser cutters may be curious: how much does it cost to buy a fiber laser cutting machine? Is it expensive?

The price of metal cutting laser machines on the market generally ranges from 1,500 US dollars to hundreds of thousands of US dollars, depending on the power and brand.

Compared with the optical fiber laser cutting machine price, the CO2 laser cutter price is lower because the former is smaller in size and power, has lower cost, and is suitable for processing non-metals.

The cost of a metal laser cutting machine is much higher than that of a CO2 laser cutting machine. On the one hand, the price of high-power lasers accounts for a large part of the cost, and on the other hand, other configurations of the machine, such as the bed, motor, and guide rail, are doubled compared to CO2 cutting machines, so the price will be higher.

To be realistic, the initial investment of fiber laser cutting machines is indeed relatively high, but a normal machine can be used for 10-15 years, and compared with the actual benefits it brings, the initial investment is completely acceptable.

Related Products

Related products

- Laser Cutting Machine

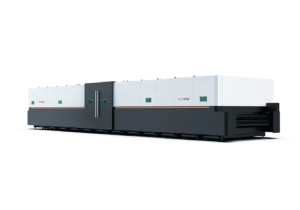

KF-series Four-head Laser Cutting Machine

- Laser Cutting Machine

XT LASER 4000w fiber laser cutting machine for sale

- Laser Cutting Machine

XT LASER 6000w fiber laser cutting machine for metal

- High Power Laser Cutting Machine

L-series Ultra Large Laser Cutting Machine