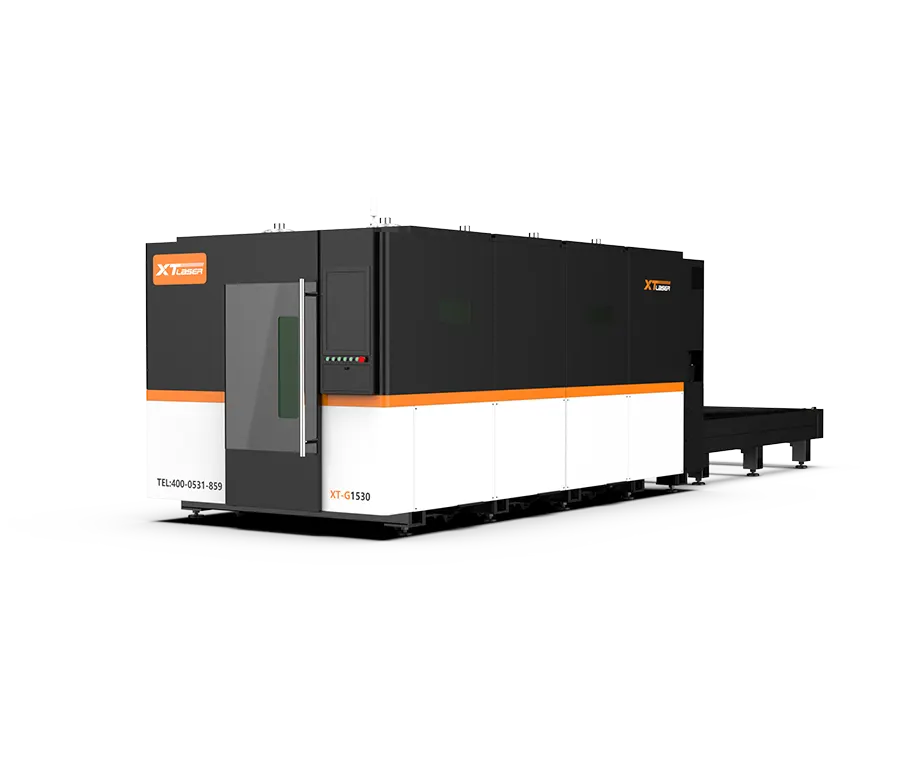

G-series Fully Enclosed Exchange Table Fiber Laser Cutting Machine

Model – G1530

Brand – XTlaser

Table Size – 1500* 3000 mm

(1500*3000 mm|2000*4000 mm|2000* 6000 mm|2500*6000 mm optional)

XTlaser’s Fully Enclosed Exchange Table Fiber Laser Cutting Machine not only achieves precision sheet metal cutting results, but also saves more time and effort by exchanging tables to maximize productivity. Fully enclosed sheet metal guards make the process safer and more environmentally friendly.

China Best Fiber Laser Cutting Machine Manufacturer

XTlaser offers customizable sheet metal laser cutting machine manufacturing services. Our business includes laser cutting, marking, welding, and cleaning. Sheet metal laser cutter can be used in a variety of industry sectors, including medical, mechanical engineering, appliance and kitchenware, fitness equipment manufacturing, and more. As long as your production is related to metal cutting, XTlaser has the right machine for you.

Whether you’re a beginner with a laser cutter or an experienced user of fiber optic laser cutters, please Contact Us.Next, let’s discover how XTlaser can help you with sheet metal cutting.

G-series Fully Enclosed Exchange Table Laser Cutter Specifications

| Machine Model | XT-G1530 | XT-G2040 | XT-G2060 | XT-G2560 |

|---|---|---|---|---|

| Working Area(mm) | 1500*3000 | 2000*4000 | 2000*6000 | 2500*6000 |

| Laser Power(W) | 1500W-6000W | |||

| Linkage Speed | 150m/min | |||

| Acceleration | 1.5G | |||

| Platform Switching Time | 25s | 30s | 35s | 35s |

| Processing Materials | Carbon steel, stainless steel, silicon steel sheet, galvanized sheet, aluminum, brass, copper, gold, silver, etc. | |||

Xt-G1530 Fully Enclosed Exchange Table Fiber Laser Cutter Details

Fully Enclosed Protective Plate + Protective Glass

Integrated Electric Control Cabinet

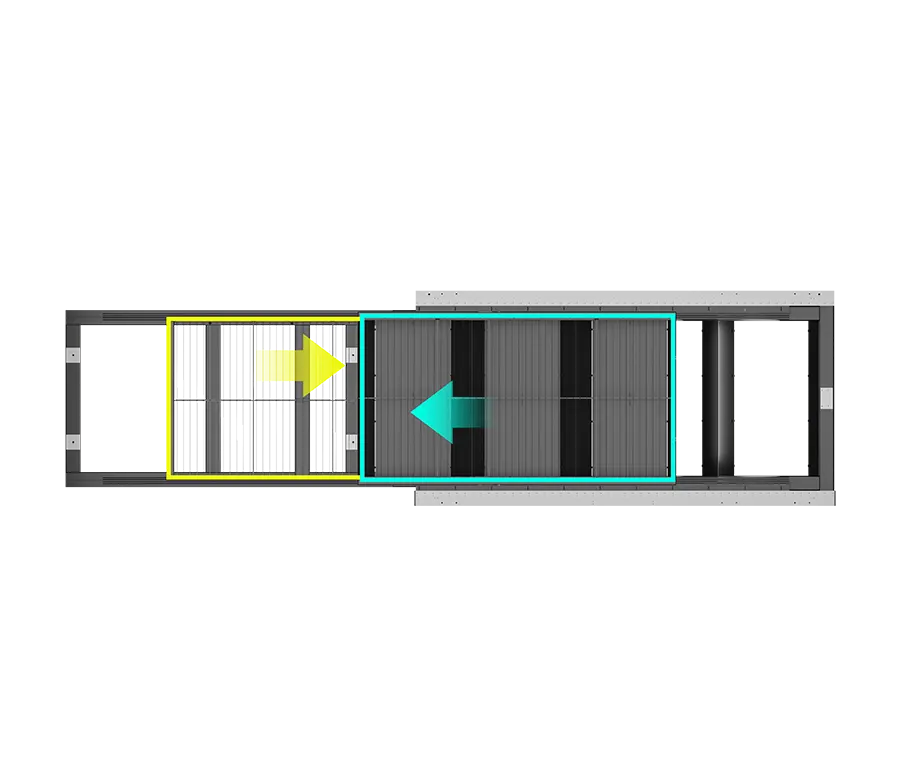

Automatic Exchange Table

Laser Power Available

Contact Us

Ready to take your sheet metal cutting to the next level? Contact us today to learn more about XTlaser’s Fully Enclosed Exchange Table Fiber Laser Cutting Machine.

Advantages of Fully Enclosed Exchange Table Fiber Laser Cutting Machine

XTlaser’s laser cutter has stood the test of time for the following reasons:

Precision Cutting

XTlaser uses advanced fiber laser technology to achieve precise positioning, ensuring consistency and accuracy in every cut, regardless of the thickness and material of the sheet metal being cut.

Safety

The fully encapsulated metal plate and fully enclosed laser shield glass design provide complete worker protection. Additional safety features such as an emergency stop button and protective barrier further enhance machine safety.

Efficient

With the dual platform table, loading and cutting are synchronized without manual intervention. While cutting one sheet of metal, another sheet can be loaded or unloaded, minimizing downtime and increasing productivity.

Simple Operation

To make it easy for operators to quickly master the use of the laser metal cutting machine, XTlaser has designed a user-friendly machine control panel and software interface to ensure that operators can easily set up production jobs and parameters.

Robust

XTlaser's Fully Enclosed Exchange Table Fiber Laser Cutting Machine is made of high-quality materials and components, such as laminate welded bed, aluminum profile beams, branded racks, guide rails, etc., which are stable and more robust and can ensure high-speed cutting for a long time.

Fiber Laser Cutting Machine Applications in Different Industries

Fiber Laser Cutting Machine can be used in almost all industries related to metal processing. The following are some of the most common applications for fiber laser machines:

In addition to the applications mentioned above, fiber laser machines are also used in the automotive, aerospace, and metal fabrication industries. xTlaser’s Fully Enclosed Exchange Table Fiber Laser Cutting Machine cuts a wide range of metals with high precision and efficiency. Maximize the productivity of your sheet metal processing.

Laser Cutting Machine Samples for Metal

Here are some samples of cuts made by the fiber laser cutting machine.

Frequently Asked Questions

XTlaser's CNC laser cutter for metal is capable of cutting a wide range of thicknesses. In general, the machine can cut sheet metal from 0.5 mm to 25mm. If you use a high-power laser cutting machine, the maximum thickness of the material that can be cut can be up to 70mm, if you want to know the specific thickness of the metal sheet that can be cut, you can click on the "Contact Us".

Our CNC laser cutter mainly cuts metal, including stainless steel, carbon steel, silicon steel, galvanized sheet, aluminum, brass, copper, gold, silver, and so on.

XTlaser's Exchange Table Fiber Laser Cutting Machine is equipped with two working tables and clicks, which can realize loading or unloading at the same time as cutting. The workflow is as follows:

While the first table is cutting, the other table is loading or unloading material;

When the cutting process of the first table is completed, the tables exchange positions automatically or manually;

This seamless exchange ensures that there is no standby time between cutting cycles, thus maximizing productivity.

Proper maintenance helps ensure optimal performance and longevity of your laser cutting machine. Below are some maintenance tips for your machine:

Clean the machine's optics, lenses, and mirrors regularly to ensure optimal laser beam quality.

Lubrication care of moving parts such as guide rails and ball screws.

Regular checking of electrical components, cooling system, and safety features to facilitate timely detection and resolution of any problems.

Follow the maintenance schedule outlined in the user manual, and feel free to contact the technical support team for any maintenance-related queries.

XTlaser provides full installation and training support to our customers to ensure that they are able to maximize the use of our laser-cutting machines. We have comprehensive laser cutting machine installation and training video materials, and any problems customers have can be solved by viewing the videos. For situations that cannot be resolved through the videos, customers can always get instant assistance through online video. If you need XTlaser's engineers to come to your factory to provide on-site installation and training services, you can contact us for solutions.

Related Products

Related products

- Laser Cutting Machine

KF-series Four-head Laser Cutting Machine

- Laser Cutting Machine

XT LASER 6000w fiber laser cutting machine for metal

- High Power Laser Cutting Machine

GP1530X High Speed Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

H-series Open Type Fiber Laser Cutting Machine