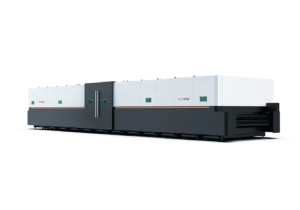

Dual Platform Picosecond Glass Laser Cutting Machine For Sale

Model – Dual Platform Picosecond Glass Laser Cutting Machine

Brand – XTlaser

Processing Size – Dual station 650mm×650mm (can be customized)

Cutting Thickness – 0.01 – 70 mm

Slit Type – one-piece slit (front cut and back split)

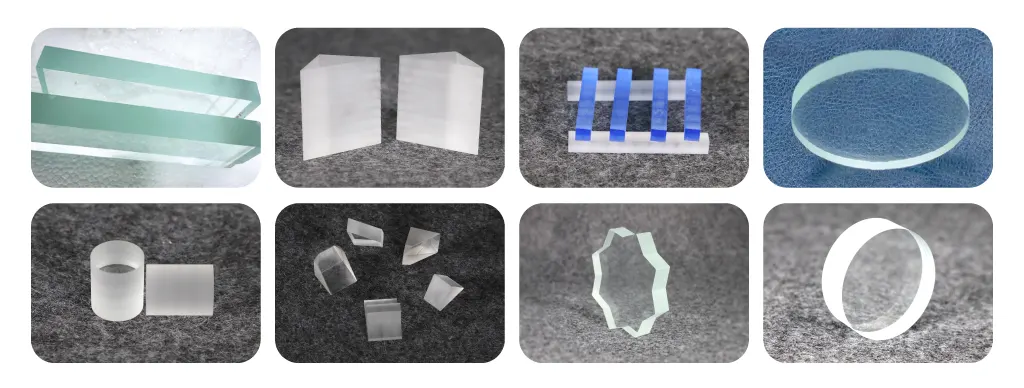

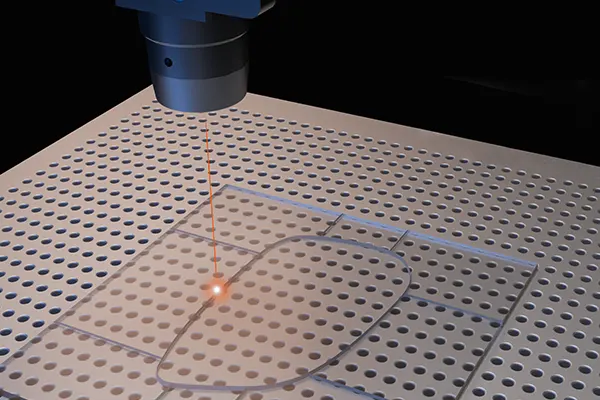

High-precision picosecond laser glass cutting machine with smooth cutting edges without burrs and small heat-affected zone is suitable for precision cutting and processing of cell phone screens, tablet PCs, automotive glass and so on.

china glass laser cutting machine

XT Laser is a leading manufacturer of high quality glass laser cutting machines in China. With years of experience and expertise in laser technology, we are committed to providing innovative and reliable solutions for global glass processing needs.

We specialize in the research, development and production of a wide range of laser cutting machines designed specifically for glass processing. Our product portfolio includes picosecond laser cutting machines for glass, laser glass frosting machines, laser glass punching machines, and more.

Contact us today to learn more about the laser glass cutting machines that will make it easy for you to achieve your glass processing goals.

Glass Laser cutting machine details

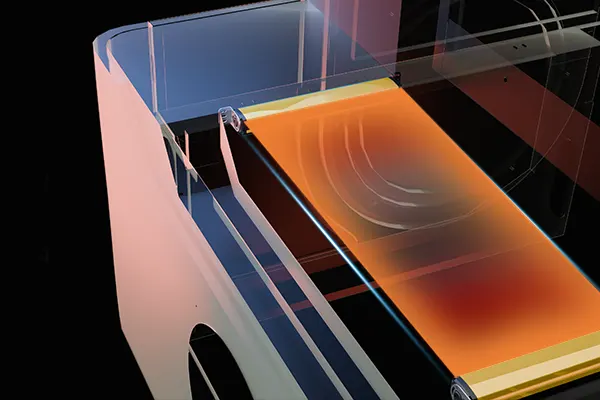

XT LASER dual-platform all-in-one picosecond glass laser cutting machine, adopting advanced picosecond laser technology and dual-platform design, realizes the double enhancement of glass cutting efficiency and precision. µm level cutting precision, perfect cutting of various complex shapes, widely used in cell phone screens, tablet PCs, automobile glass and other fields.

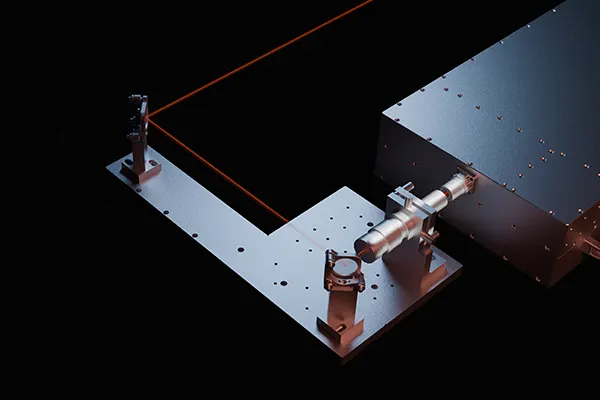

High-quality kernel light source

- Adopting high-quality picosecond laser of international leading brand, with stable output and high peak power to ensure cutting efficiency and quality.

- Compared with nanosecond lasers, picosecond lasers have shorter pulse widths, smaller heat-affected zones, smoother cutting edges, and are more suitable for fine processing, especially for heat-sensitive glass materials.

Marble Platform

- Double platform cnc laser glass cutting machine adopts marble platform, which is solid and stable.

- The marble platform has good shock absorption and stability, which can effectively reduce vibration during processing and improve cutting accuracy.

- The marble platform's advantages of corrosion resistance, abrasion resistance, easy to clean, etc., can maintain a good working condition for a long time.

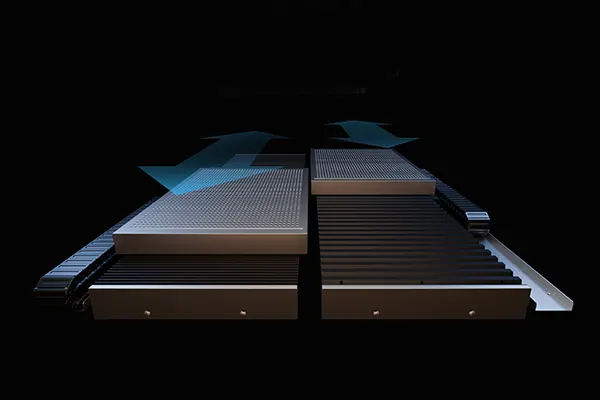

Exchange platform

- Dual platform design can realize the separation of machining station and loading/unloading station, reduce waiting time and improve production efficiency.

- Operators can carry out processing operations on one platform while loading or unloading operations are carried out on another platform, realizing continuous processing without stopping and waiting, which greatly improves the production efficiency.

Intelligent Grating

- Intelligent grating can monitor the laser glass cutting machine processing area in real time, when a person enters the dangerous area, immediately stop the laser work to ensure the safety of operation.

- This non-contact safety protection method, fast response speed, high reliability, to provide operators with a full range of security.

Efficient dual position control linkage

- Efficient linkage control system can realize fast and accurate positioning, improve cutting efficiency and precision.

- Through the precise control of X, Y and Z axes, it can realize the cutting of various complex shapes and meet the processing needs of different products.

Contact Us

Fill out the form for professional support!

Why choose XT LASER cnc glass laser cutting machine?

Industry Leadership

XT LASER has been deeply engaged in the laser equipment industry for many years, whether it is metal laser cutting machine or glass laser cutting machine, has rich experience in research and development and manufacturing, and has strong technical strength. Experienced and skilled R & D team, continuous technological innovation and product upgrading, always maintain the industry leading position.

Quality Assurance

XT LASER has established a strict quality control system, from raw material procurement to equipment shipment, each process is professionally installed by operators and strictly inspected by quality inspectors to ensure the stable and reliable quality of glass cutting laser machine.

Customized Service

XT LASER tries its best to satisfy every customer's needs and provide customized service. For example: laser power, processing width, automation degree, etc., to meet the customized needs of different customers.

Perfect after-sales service

XT LASER has a professional after-sales service team, providing 7x24 hours technical support and service, for any problems you encountered will provide timely help, eliminating your worries. You don't need to worry about the after-sales problem when you choose XT LASER cnc laser cutting machine for glass.

Applications of laser glass cutting machine

Frequently Asked Questions

Picosecond laser glass cutting machine as a kind of advanced precision processing equipment, its price is affected by many factors.

First of all, the power of the laser is one of the most important factors in determining the price. The higher the power, the stronger the cutting ability, the higher the processing efficiency, the corresponding price will be higher.

Secondly, the processing width is also an important factor affecting the laser glass cutting machine price, the larger the processing width, the larger the size of the glass can be processed, the price will naturally be higher.

In addition, the specific configuration of the equipment will also have an impact on the price. For example, whether it is equipped with dual platform, with or without visual recognition system, CCD monitoring system, etc., will affect the final price.

Generally speaking, picosecond laser glass cutting machine price ranges from tens of thousands to hundreds of thousands of dollars. If you need more precise configuration and its price, please contact us.

XT LASER's sales staff will customize the most suitable equipment configuration plan for you according to your needs and provide detailed quotation information.

The range of glass thicknesses that can be cut with a picosecond laser glass cutter depends on the power of the laser and the type of glass. Generally speaking, the thickness of glass that can be cut is between 0.1mm and 10mm. For some special application scenarios, such as cutting ultra-thin or thick glass, you may need to choose a higher power laser or a special cutting process.

Choosing the right picosecond laser glass cutter requires a combination of factors, careful evaluation of your needs and budget to make the best decision.

- Define your processing needs: First of all, you should define your processing needs, such as: the type of glass you need to cut, thickness, size, shape, precision requirements, efficiency requirements, and so on.

If you need to cut ultra-thin glass or thick glass, you need to choose a higher power laser.

If you have very high requirements for cutting accuracy, you need to choose equipment equipped with high-precision motion control system and visual recognition system.

If you need to process large quantities of glass with high efficiency, you need to consider equipment with automation features such as dual platforms and automatic loading and unloading systems. - Determine the budget: Picosecond laser glass cutting machine is a high-end precision processing equipment, the price is higher, so you need to choose according to your budget. When determining your budget, you should not only consider the initial purchase cost of the equipment, but also the running cost, maintenance cost, and consumable cost of the equipment.

- Choose the right brand: By choosing equipment from a well-known brand, you can get better quality assurance and after-sales service. Famous brand equipment usually adopts more advanced technology and more reliable components, with higher stability and reliability, which can effectively reduce the equipment failure rate and maintenance costs. In addition, well-known brands usually have more perfect after-sales service system, can provide you with timely technical support and service, to eliminate your worries.

- Examine the performance of the equipment: When choosing equipment, you need to examine the performance of the equipment, such as: cutting accuracy, cutting speed, stability, reliability and so on. You can check the technical parameters of the equipment, watch the demonstration video of the equipment, visit the production site of the equipment, etc., to assess the performance of the equipment.

- Focus on after-sales service: After-sales service is one of the important factors in choosing equipment. Perfect after-sales service can ensure the normal operation of the equipment, timely resolution of equipment failure, reduce downtime and improve production efficiency. When choosing equipment, you need to understand the content of the after-sales service provided by the supplier, such as: warranty period, technical support, supply of spare parts, maintenance services and so on.

Other Products

- Laser Cutting Machine

KF-series Four-head Laser Cutting Machine

- Automation Equipment

TF-series 3D Five-Axis Laser Cutting Machine

- Laser Cutting Machine

XT LASER 4000w fiber laser cutting machine for sale