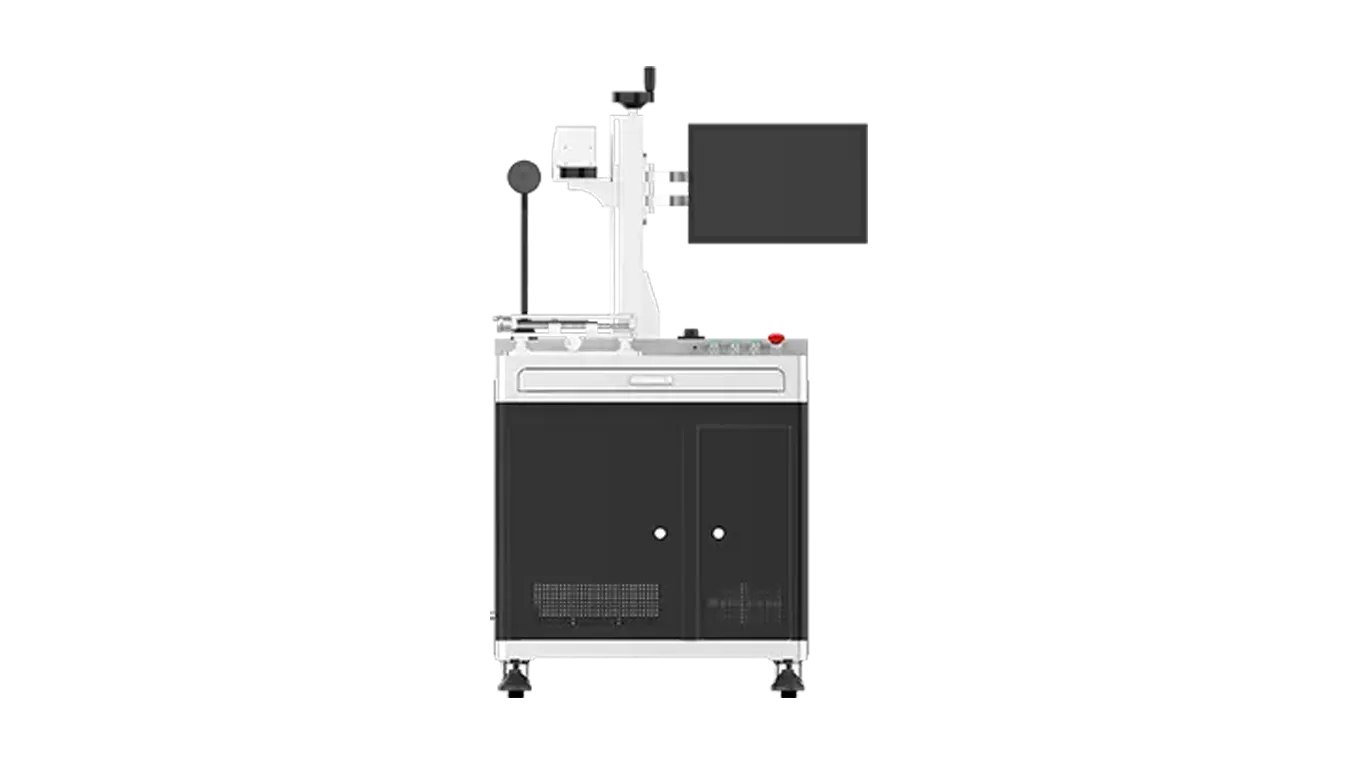

China Desktop Fiber Laser Marking Machine Factory

Desktop fiber laser marking machines are compact devices designed for industrial marking needs. Advanced laser technology enables permanent marking on various materials such as metal, plastic, ceramic, and glass. With features like clear marking, high precision, fast speed, stable performance, and minimal damage, they have become indispensable marking tools in modern industries.

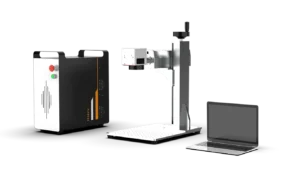

XTLASER, a professional laser marker machine factory, manufactures a variety of laser marking machines with years of experience. We offer multiple marking solutions, including closed laser marking machines, portable laser marking machines, and mini laser marking machines. We guarantee quality and worry-free after-sales service.

Fiber Laser Marking Machine Details

Integrated Design

- Integrated laser control card, no need for an external computer, easy to operate.

- Knob adjustment for marking height, simple and convenient.

- Integrated design saves space and is easy to store and place.

Visual Display Screen

- Equipped with a visual display screen, allowing users to set the marking position and size.

- Visual operation interface, easy to learn and operate.

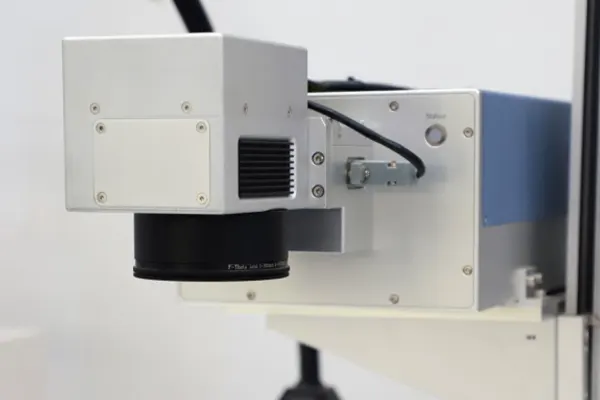

High-Quality Components

- Metal galvanometer for finer marking results.

- High-quality RAYCUS laser source for stable laser output and clear, non-fading marks.

Expandable Options

- Optional rotary axis for 3D laser marking, meeting the needs of complex curved or irregular surfaces.

- Customized functions such as auto-focus and visual positioning are available upon request, improving marking efficiency and accuracy.

Contact Us

Fill out the form for professional support!

Why Choose XTLASER Fiber Laser Marking Machine?

Easy to Operate

Equipped with a visual display for convenient and intuitive operation. XTLASER provides professional laser marking machine training and technical support to ensure operators can quickly get started.

Low Maintenance Cost

Laser marker machines have a long lifespan, up to 100,000 hours or more. The whole machine adopts a maintenance-free design with no wearing parts, eliminating the need for frequent replacement of consumables and reducing operating costs.

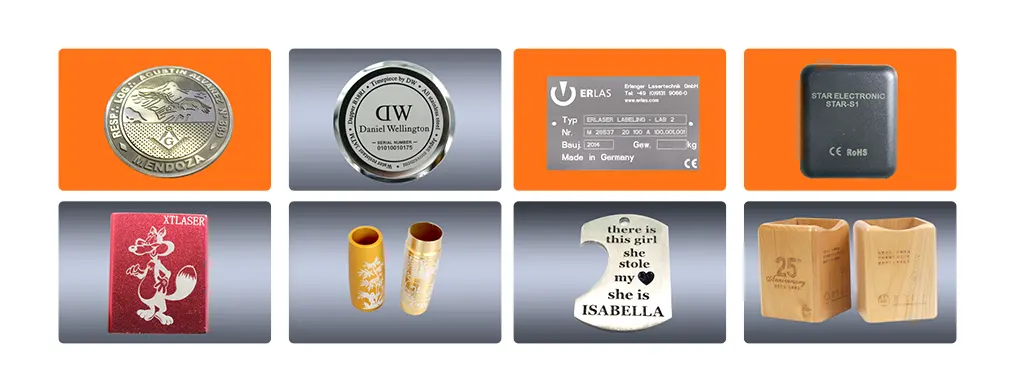

Multi-Functionality

Laser marker supports various marking modes, such as text, graphics, QR codes, etc. Laser marking machine can mark on both metal and non-metal surfaces, such as gold, silver, copper, iron, most plastics, ceramics, glass, etc.

Energy-Saving and Environmentally Friendly

Laser marking process produces no smoke pollution or noise, meeting environmental protection requirements.The whole machine has low power consumption, saving energy.

Application areas of laser marker machines

Frequently Asked Questions

Laser marking uses a high-density laser beam to locally irradiate the surface of an object, causing the surface material to vaporize and leave an ablation mark.

During the entire marking process, there is no contact with the object, and the object does not deform. Fiber laser marking is suitable for most metal materials and some non-metal materials.

What are the common power options for fiber laser markers?

Common fiber laser markers include 20W, 30W, 50W, 100W, etc. A 20-watt fiber laser marking machine can achieve surface marking, while deeper marking generally requires 30W or higher laser marking machines.

Can laser marking be used for small business?

Laser marking can be used for small business, such as marking patterns on keychains, making metal nameplates, engraving rings, marking gifts, and other customized services. Additionally, laser marking can also be used in industry, such as engine body coding, frame numbering, carbon steel pipe marking, etc.

It is normal to want to know the price of an item before purchasing it, and the same goes for laser marking machines. There are various types of marking machines on the market, and the price of laser marking machines varies depending on the machine type, power, configuration, etc.

The price of a 10W fiber laser marking machine is different from that of a 50W laser marking machine. The price to buy a desktop fiber laser marking machine is generally between 3,000 USD and 6,000 USD.

For specific prices and configurations, please consult XTLASER.

If you order a standard configuration laser marker from XTLASER, we will arrange shipment within 7-15 days. We can ship so quickly because XTLASER always ensures that fiber laser marking machines are in stock so that customers can receive their machines as soon as possible after placing an order.

If you order a non-standard model, we will complete the shipment within 15-30 days. You can contact our customer service staff to confirm the specific delivery time.

The depth of engraving of a laser marking machine is affected by various factors, such as laser power, material type, engraving speed, marking density and area, etc.

- Laser power: The higher the laser power, the deeper the engraving. However, excessive power may cause the material to burn or melt, so reasonable configuration of laser power is needed to achieve the desired engraving effect.

- Material type and hardness: Different types of materials react differently to lasers, and their thermal resistance will also affect the engraving depth. Generally, the engraving depth of metal materials is shallower than that of non-metal materials. At the same time, the harder the material, the shallower the engraving depth.

- Engraving speed: The faster the engraving speed of the laser engraving marking machine, the longer the action time on the material, resulting in a deeper engraving depth.

- Beam focusing: The quality of beam focusing directly affects the engraving depth. The better the focus, the more concentrated the laser energy, and the greater the engraving depth.

- Focal length: Focal length refers to the distance between the laser head and the surface of the workpiece. The shorter the focal length, the more concentrated the laser energy, and the deeper the engraving depth. Therefore, corresponding focal length adjustments are needed for different materials and engraving depth requirements.

- Lens cleanliness: If there is dust or dirt on the surface of the lens, it will affect the penetration ability of the laser, resulting in insufficient engraving depth. Therefore, ensure the lens is clean before using the laser marking machine.

- Marking density and area: Under the same area, the higher the marking density, the slower the marking speed, resulting in a deeper engraving depth. At the same time, the marking speed of a large area is usually slower than that of a small area, and a large area requires replacing a larger marking field lens, which will affect the concentrated light energy and thus affect the engraving depth.

The above are the common factors affecting the engraving effect of laser engraving marking machine, hope the above can solve some of your doubts.

Related Products

Related products

- Laser Marking Machine

Enclosed Laser Fiber Marking Machine

- Laser Marking Machine

Mini Portable Laser Marking Machine