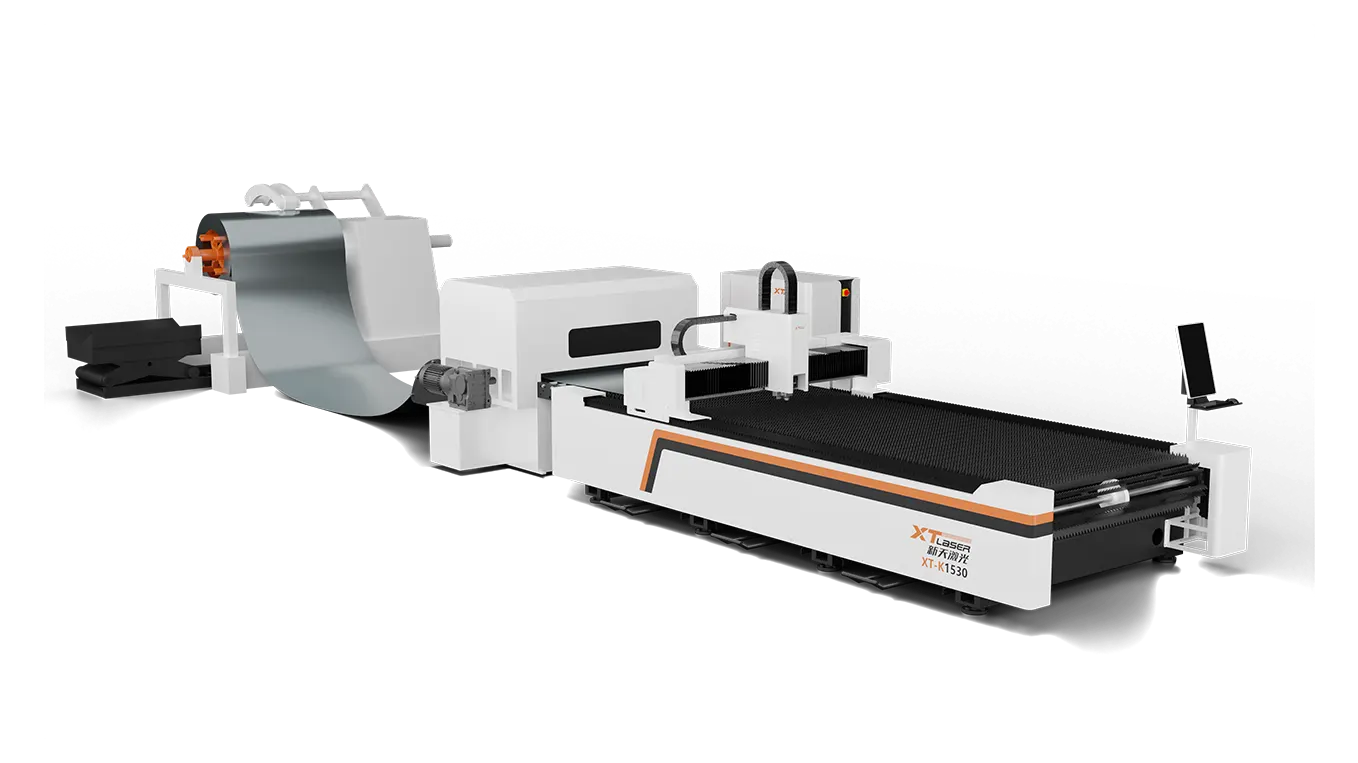

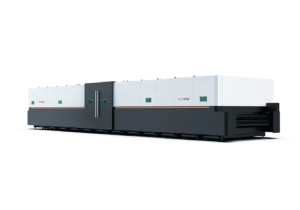

K Series Coil Fed Laser Cutting Machine

Model – Coil Fed Laser Cutting Machine

Brand – XTlaser

Processing Area – 3000mm*1550mm

Plate Thickness Range – 0.5 – 2mm

Coil Outer Diameter – φ1000mm – φ1500mm

Coil Inner Diameter – φ508mm – φ610mm

The coil fed laser cutting machine combines the unwinding, leveling, feeding, cutting, and unloading of metal materials into one, realizing automation from beginning to end, ensuring the quality of material processing and saving labor costs.

Best coil fed laser cutting machine manufacturer

In order to solve production efficiency problems such as coil and blanking, the XTLASER coil laser cutting machine factory has established a new standard for unwinding and cutting.

A steel coil laser cutting machine can realize four functions unwinding, leveling, cutting, and unloading, breaking the traditional metal coil processing method.

coil-fed fiber laser cutting machine specifications

| Working Area | 3000mm*1550mm |

|---|---|

| Table load capacity | 120KG |

| Linkage speed | 140m/min |

| Acceleration | 1.2G |

| Plate thickness | 0.5-3mm |

| Coil outer diameter | φ1000mm-φ1500mm |

| Coil inner diameter | φ508mm-φ610mm |

| Maximum weight per coil | ≤7t |

coil cnc fiber laser cutting machine details

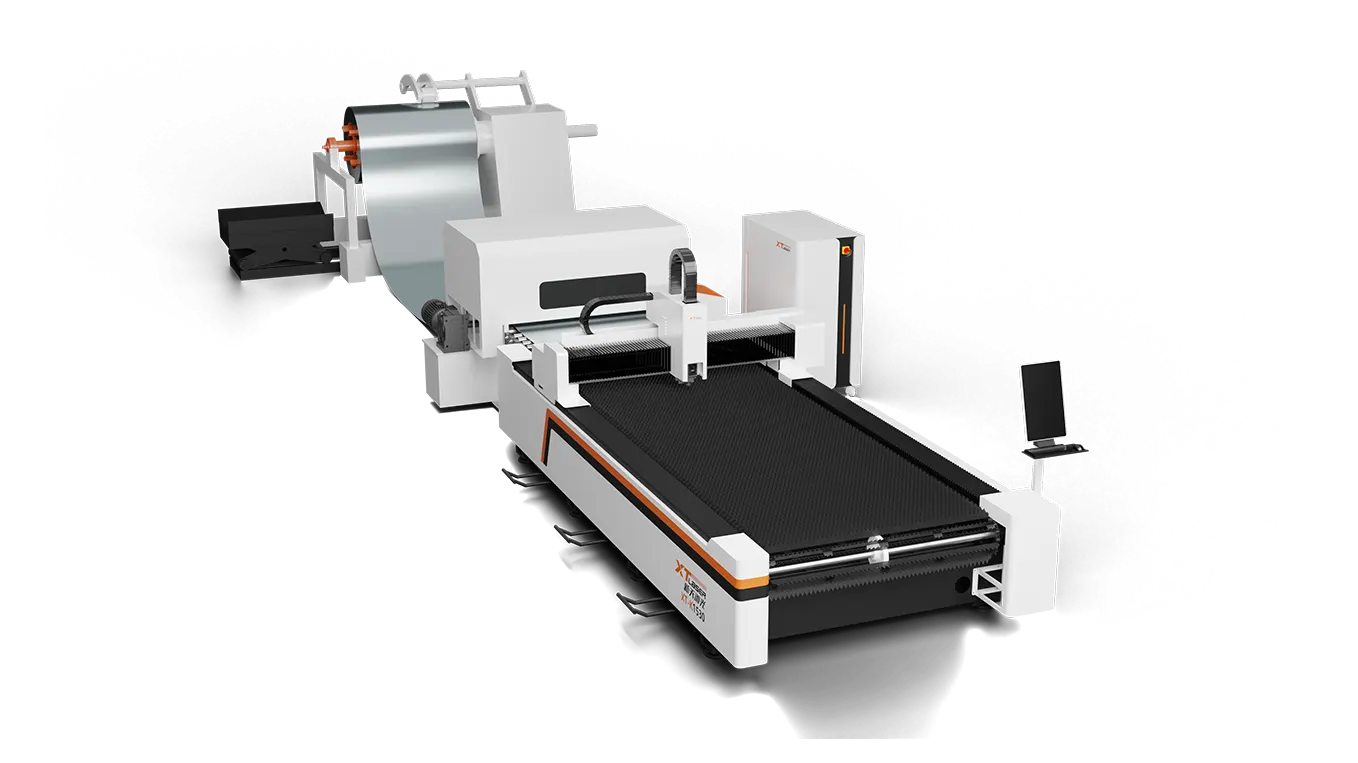

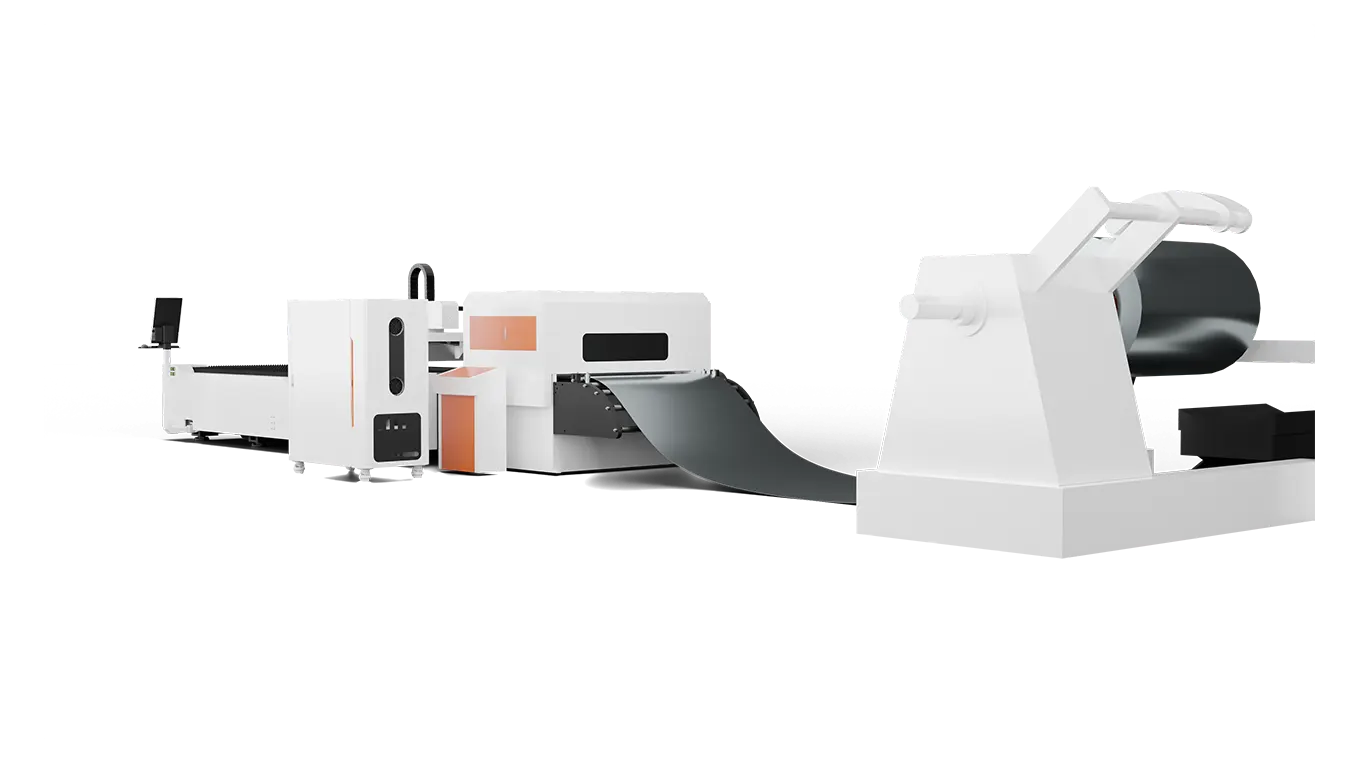

Automatic unwinding and leveling

- The uncoiler can align various thicknesses and widths of wire steel plates and uneven plates, effectively eliminating irregular shapes such as bending and warping generated during the manufacturing or transportation of plates.

- After the coil is unwound, the steel coil enters the leveling machine to further level the plate, to ensure the accuracy of subsequent processing and the overall quality of the product.

Transfer to laser cutting machine table

- The leveled plate is transferred to the processing table of the laser cutting machine. The cutting machine is equipped with a crawler cutting table. During the processing, the cutting table runs synchronously with the servo feeding to realize coil cutting.

- The laser cutting machine has the functions of automatic edge finding and cutting, which can meet all the requirements of thin plate cutting.

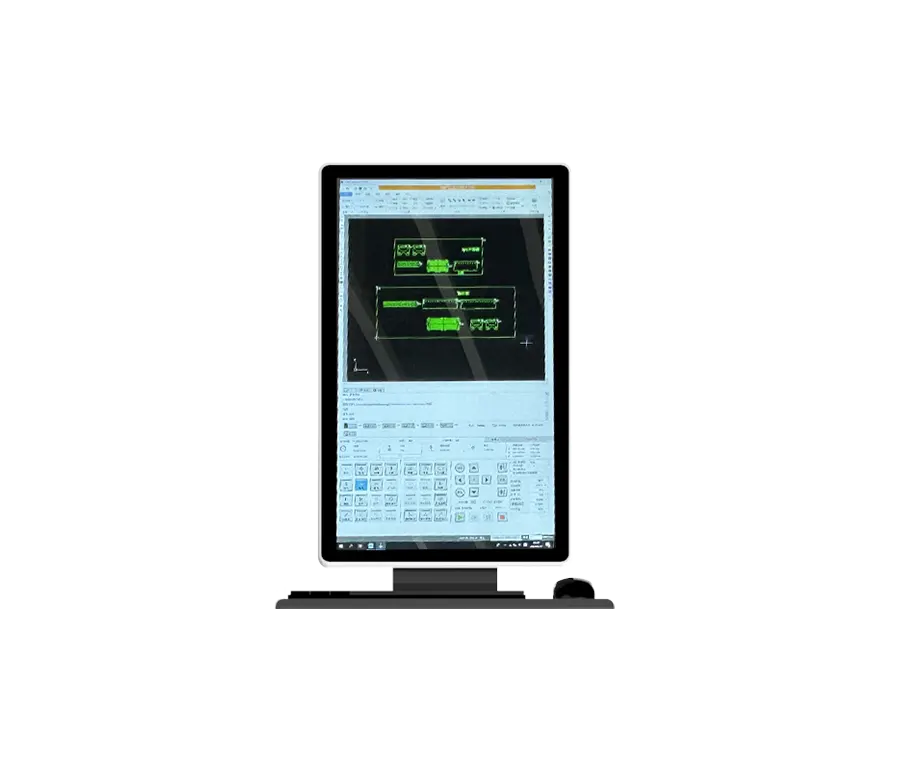

Intelligent control system

- The professional laser cutting control system is equipped with a large screen display, and the interface is simple and clear, easy to learn and use.

- Install intelligent typesetting software to maximize material utilization and reduce waste.

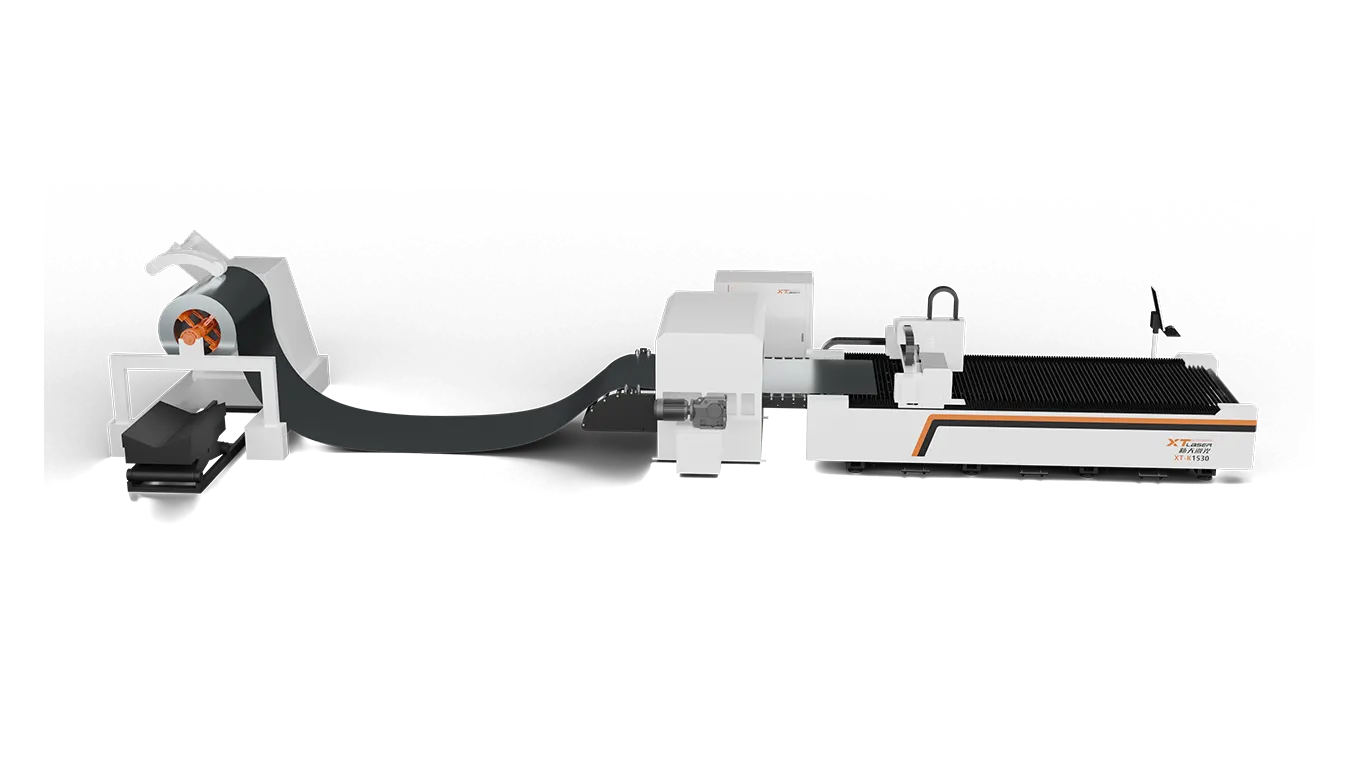

Continuous cutting is available

- The automatic coil fiber laser cutting machine can realize 24-hour non-stop operation, cutting and feeding continuous operation, and continuous cutting, greatly improving production efficiency.

Contact Us

Fill out the form for professional support!

Why choose a coil feed laser cutting machine?

High-precision

Laser cutting can achieve millimeter-level precision, small cutting errors of metal, a smooth and flat cutting surface without burrs, and no micro-cracks, eliminating secondary processing.

Automated production

From unwinding to leveling and then to cutting, the whole process of automatic production is realized, without manual intervention, saving time and high efficiency.

Improve production efficiency

The coil conveying equipment is continuously conveyed, and the feeding and discharging are carried out synchronously. The superior continuous conveying and seamless power-cutting connection greatly save time and improve productivity for users.

High material utilization rate

Using coil for continuous production, no loss of head and tail is generated; At the same time, the equipment adopts an optimized layout, combines parts of various shapes for cutting without overlapping edges, reduces material loss, and improves material utilization.

Applications of coil laser cutting machine

This multi-functional integrated and highly automated production solution of coil-fed fiber laser cutting machine is especially suitable for industries that need to process a large number of varieties and large-size metal sheets in large quantities.

Frequently Asked Questions

The coil laser cutting machine consists of a programming system, automatic unwinding, a leveling system, automatic feeding, and laser cutting. It can realize automatic production, greatly improve production efficiency, effectively reduce labor burden, reduce production cost, and has the characteristics of high precision, convenience, and continuous operation.

Technical features of coil laser cutting production line

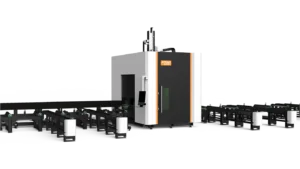

The coil CNC fiber laser cutting machine adopts a professional system to control the motor synchronously. The working table of the cutting machine is a crawler-type cutting table, and the crawler is equipped with a needle plate-type cutting strip.

During processing, the cutting table runs synchronously with the uncoiling servo feeding at the same speed to realize coil cutting. It is suitable for processing metal coils within 3mm, the repeated positioning accuracy can reach ± 0.03mm, and the positioning accuracy is within ± 0.05mm/m.

The fuselage of the coil-fed fiber laser cutting machine adopts steel plate welded structure and is tempered at high temperatures to completely eliminate welding stress. When processing, a CNC gantry milling machine is used to process the guide rail and rack device surface on both sides of the bed at one time, ensuring the consistency of the guide rail and rack device surface accuracy on both sides of the frame.

The correction wheel of the leveling machine is made of bearing steel, and the outer surface is thickened by electroplating, which is durable. The operation is simple and convenient. All the correction wheels adopt gear transmission and are equipped with backup pressure wheels, which can effectively enhance the rigidity of the correction wheels and improve the correction quality.

The coil fed laser cutting machine price on the market is generally between tens of thousands of dollars and hundreds of thousands of dollars.

The coil fed laser cutting machine is mainly composed of an uncoiled, leveling machine, and laser cutting machine, and each part will affect the final price of the machine. However, the following aspects play a decisive role in the price:

Laser Power

The power of the laser is very important to the accuracy of the coil fed laser cutting machine. Higher power lasers can often cut thick materials faster and more accurately, but the price will also increase accordingly.

Machine Configuration

Each customer has different requirements for machine configuration. The processing size of the machine, the thickness of the metal plate that can be processed, whether it is equipped with automatic blanking, etc. will affect the final quotation.

Transmission System

Compared with other single metal laser cutting machines, the whole coil laser cutting machine production line is equipped with a large number of transmission parts, such as servo motors, guide rails, racks, etc. Customers' different requirements for transmission parts affect the final machine price.

In addition to the above, brand influence, after-sales service, and personalized customization also affect the price. Understanding these factors can help you better evaluate the cost performance of the equipment and choose the coil fed laser cutting machine that best suits your needs.

XTLASER coil fed laser cutting machine can cut 0.5-2mm metal coils, such as stainless steel, steel, aluminum, etc.

In addition, the standard model can unwind metal coils with an outer diameter of φ 1000mm-φ 1500mm and an inner diameter of φ 508mm-φ 610mm.

If you need a non-standard model, please feel free to contact us. XTLASER has professional sales and technical personnel who will answer your questions and recommend suitable machine configurations according to your needs.

Releated Products

Related products

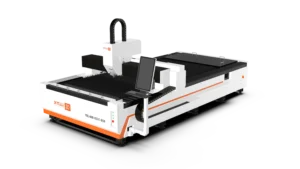

- Laser Cutting Machine

KF-series Four-head Laser Cutting Machine

- Laser Cutting Machine

XT LASER 6000w fiber laser cutting machine for metal

- High Power Laser Cutting Machine

XT LASER 12000W fiber laser cutting machine with 1500×3000mm working area

- Laser Cutting Machine

HR Series H Beam Laser Cutting Machine