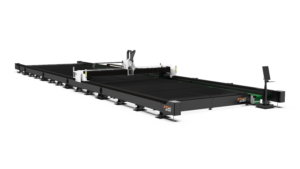

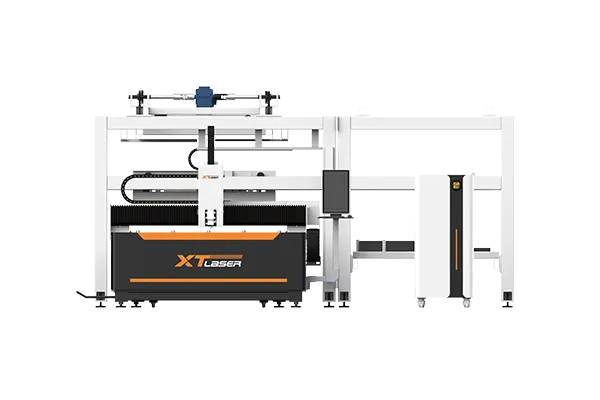

The XTlaser automatic loading and unloading laser cutting machine is suitable for customers who require automation of medium to large quantities of sheet metal. The machine enables the automatic loading and unloading of raw materials and the collection and storage of finished products cost-effectively and efficiently.

XTlaser - Effecively Fiber Laser Cutting Machine Factory in China

XTlaser offers customized laser cutting machines with customized dimensions, laser power, and automatic loading and unloading systems.

Automatic loading and unloading laser cutting machines can be used in a variety of industries, such as sheet metal processing, automotive manufacturing, medical, and pharmaceutical.

For your laser cutting project, please contact us. We will help you find the most suitable laser cutting solution.

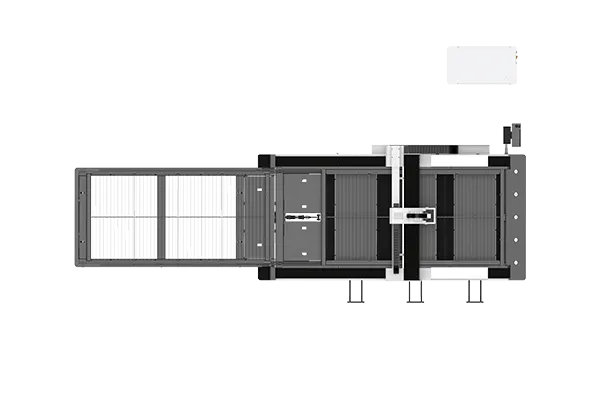

Plate Laser Cutting Machine With Automated System Specifications

| Machine Model | XT-E1530A | XT-G1560A (With Metal Cover) |

|---|---|---|

| Laser Power(W) | 1500W-4000W | 1500W-6000W |

| Max Loading Zone | 3000 mm*1500 mm | |

| Min Loading Zone | 1000 mm * 1000 mm | |

| Max Loading Weight | 700 KG | |

| Max Thickness(loading plate) | 20 mm | |

| Min Thickness(loading plate) | 1 mm | |

| Processing Materials | Carbon steel, stainless steel, silicon steel sheet, galvanized sheet, aluminum, brass, copper, gold, silver, etc. | |

Auto Loading and Unloading Fiber Laser Cutting Machine Details

Time-saving

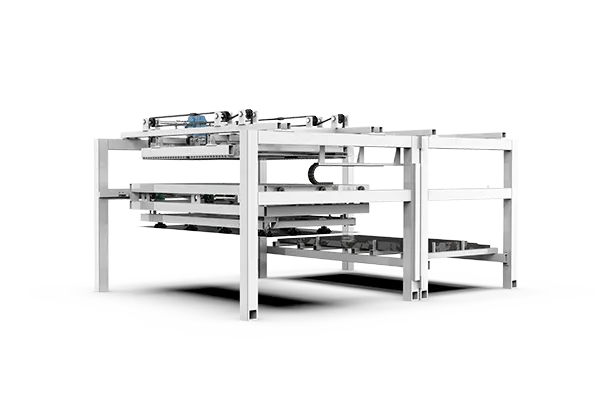

Automatic Loading and Unloading System

- 12 large suction cups and 3 small suction cups can easily pick up metal sheets up to 10mm thick.

- Intelligent detection of thin and light metal sheets prevents simultaneous loading and unloading of several sheets at a time.

- Equipped with raw material pallets and finished product pallets, realizing the automatic call and storage of raw material and finished products.

- Reduces the work intensity of workers and saves labor costs.

High Effective

Dual Exchange Table

- Cutting at the front table and loading or unloading at the rear table, saves time and efficiency.

- Dual motorized conveyor system for quick switching of work surfaces.

- Customized table size according to customer's requirement.

Convenient

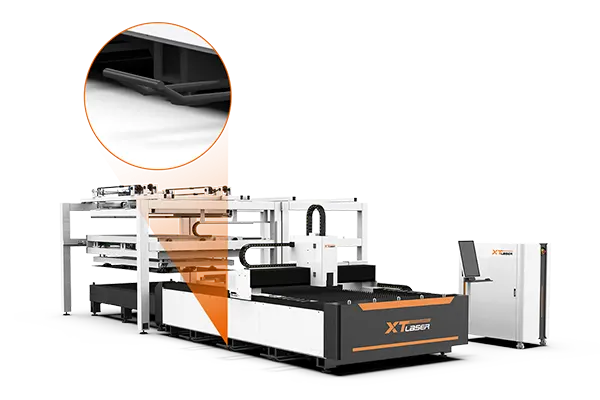

Finished Material Sliding Table

- Adopting pull-out and movable design, the position of the receiving platform can be selected according to the need.

- Catch small metal parts or scraps dropped during machining, convenient for workpiece collection.

Stable

Laser Cutting Machine

- Adopting high-quality steel welding bed, after surface treatment and painting, corrosion resistance, and low vibration, to ensure cutting accuracy.

- Aluminum profile beam is lightweight and high rigidity, reducing the pressure on other parts of the laser cutting machine and prolonging the service life of the equipment.

- Independent electronic control cabinet can be placed according to the need for cabinet location, easy maintenance, and heat dissipation.

Why Choose XTlaser Automation Laser Metal Cutting Machine?

Customers choose XTlaser for a variety of reasons, such as the quality of the machine, the excellent service, and the cost-effectiveness of the machine. Some of the benefits are listed below:

Source Manufacturer

XTlaser uses own branded accessories, such as a dust collector, water cooler, voltage regulator, etc. No middleman to make a price difference. Compared with other CNC laser Cutting Machine Suppliers, choosing XTlaser is more cost-effective.

Certified and Quality Assured

XTlaser's laser cutting machines, laser tube cutter, laser marking machine, and laser welding machine are all certified by EU Ce and ISO9001, and we have also obtained the American FDA certificate, UL certificate, and so on.

Customized Service

We offer customized services to meet different laser metal cutting machine needs. Whether it is the processing size of the machine, the power of the laser, or the automatic loading and unloading system, all of them can be selected according to the customer's requirements.

Guaranteed After-sales Service

XTlaser does not only pay attention to the quality of the fibre laser machine but also to the customer service experience. Therefore, we have set up several offices at home and abroad, so that customers can enjoy the "door-to-door" service.

Contact Us

Not sure if your pipes are suitable for XTlaser’s laser cutting machine? Contact us for the most professional consulting services.

Applications of Automated Fiber Laser Cutting Machine

The application of fibre laser cutting machines greatly improves the precision of metal processing, and the clever combination of automatic loading and unloading systems and CNC laser cuts greatly improves the speed of metal cutting and saves time and manpower costs for more enterprises.

Laser Cutting Machine Samples for Metal

XTlaser EA-Series laser cutting machine with automatic loading and unloading system can achieve carbon steel, stainless steel, silicon steel sheet, aluminum, copper and other metal plate cutting, as well as round, square, and rectangular metal pipe cutting.

Frequently Asked Questions

Our Automatic loading and unloading fibre laser cutting machine adopts advanced automation technology and is equipped with dedicated loading and unloading systems.

Sensors and control systems enable automatic feeding and unloading of material without the need for human intervention, increasing productivity.

XTlaser's auto-loading and unloading laser cutting machine is equipped with an intuitive user interface and intelligent control system.

There are no complicated operating steps and workers can learn how to use the machine after one day of training. The machine can be set up in a few simple steps.

In the process of using the machine, if there are any difficulties encountered, XTlaser's after-sales support team is online all day long, ready to solve your operation problems.

Of course, you can. We set up the machine configuration according to the customer's actual needs.

The automatic loading and unloading system is suitable for manufacturers who want to process large quantities of sheet metal and increase productivity.

If you don't have such a need, XTlaser's open type exchange table fibre laser cutting machine and high-power laser cutting machine can meet your needs.

Related Products

Related products

- Sheet Metal Laser Cutting Machine

W-series Single Table Fiber Laser Cutting Machine

- High Power Laser Cutting Machine

L-series Ultra Large Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

H-series Open Type Fiber Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

G-series Fully Enclosed Exchange Table Fiber Laser Cutting Machine