Automatic Bending Machine For Sheet Metal

Model – Automatic Bending Machine For Sheet Metal

Brand – XTlaser

Max. Bending Width – 1500mm

Bending Angle – 0-180°

Max. Bending Speed – 0.2s/Bending

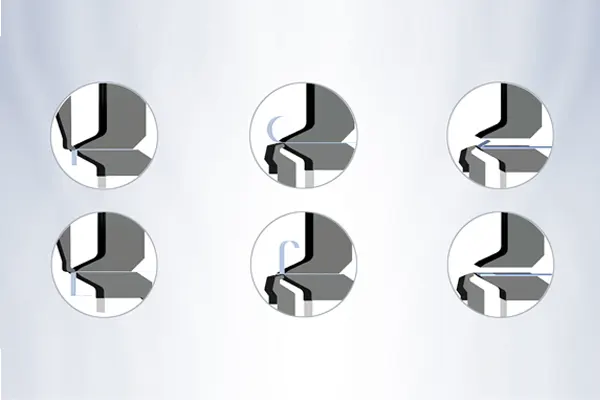

The automatic bending machine adopts full electric servo control and realizes the actions of up-bending, down-bending, bending at any angle, and rotation of metal workpieces through universal bending dies.

China Automatic Bending Machine Supplier

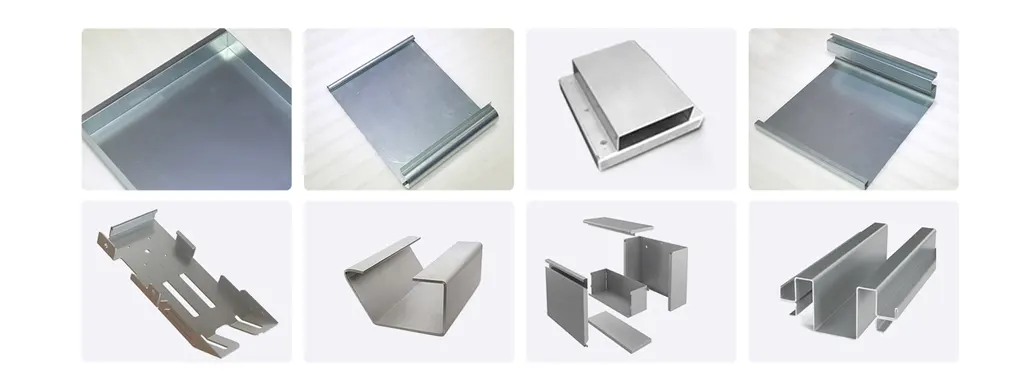

The automatic metal bending machine is an intelligent bending equipment with automatic positioning and bending functions. Simply place the workpiece on the workbench, and it can automatically position and bend the workpiece, and can complete various door industry processes such as door frames, door panels, and mother-and-child doors. The average workpiece takes 30 seconds, effectively improving production efficiency.

XTLASER is an automatic bending machine supplier integrating product research and development, function customization, manufacturing, and after-sales service. The automatic CNC bending machine is directly sold by the manufacturer, not only with guaranteed quality but also with more favorable prices.

automatic sheet metal bending machine Specifications

| Model | Parameter | Model | Parameter |

|---|---|---|---|

| Feeding Structure | Suction Cup | Minimum Arc Radius | 6mm |

| Number of Axes | Standard 10 Axes | Maximum Bending Speed | 0.2s/Bending |

| Max. Bending Width | 1500mm | Max. Fast Forward Speed | 12m/min |

| Maximum Bending Height | 170mm | Bending Angle | 0-180° |

| Minimum Inside Dimensions of One Side of the Molding | 180mm | Maximum Bending Thickness | 1.5mm Ordinary Steel Plate/1mm Stainless Steel/2mm Aluminum Plate |

| Minimum Inside Dimensions for Four Sides | 410mm×340mm | Rated Voltage | 380V AC |

| Maximum Unfolding Length of Sheet Metal | 1600mm | Total Power | Approx. 40KW |

| Maximum Spreading Width of Sheet Metal | 1250mm | Average Power | Approx. 2KW |

automatic CNC bending machine Details

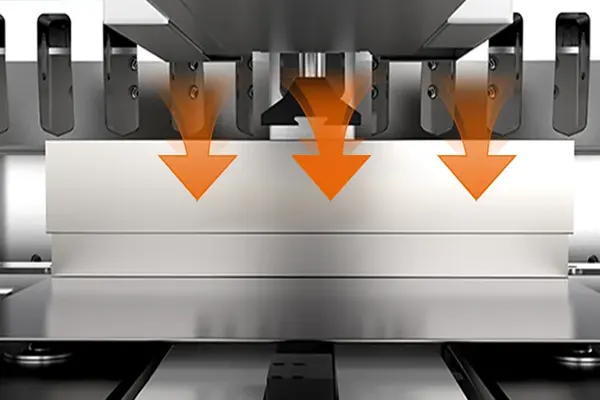

Equipped with Multi-functional Dies

- It can bend metal workpieces of different sizes, thicknesses, and angles.

- Without the need for custom molds, a set of universal bending molds can easily complete arcs, hemming, return bends, closed shapes, and other complex bending shapes.

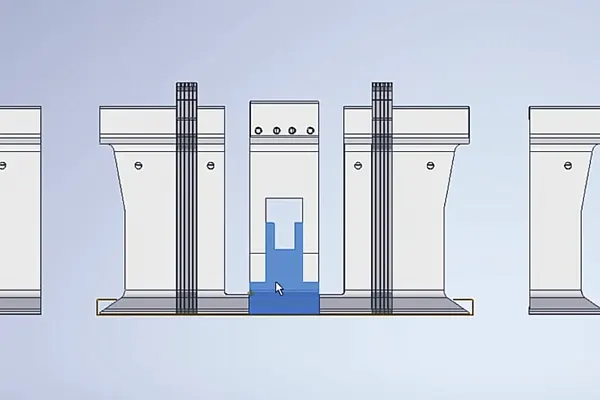

Automatic Blade Arrangement and Retraction

- According to the size of the workpiece, automatically calculate the pressing position smaller than the workpiece and realize automatic blade arrangement.

- When bending box-type workpieces, the machine algorithm automatically arranges the blades, shrinks or expands the mold as needed, and realizes the bending steps of the workpiece through the avoidance function.

Fully Automatic Bending

- Workers only need to load and unload materials, and the equipment automatically positions and bends automatically. Ordinary operators can learn it in only 2 hours.

- No manual turning is required, the bending process is fully automated, the fastest is 0.2s/bending, an average of 30s for one workpiece, and the efficiency is increased by 3-5 times.

High Bending Accuracy

- The full electric servo controls the expansion and contraction of the hinge blade, without contact with the workpiece, and does not generate any lateral shovel force.

- No scratches, no shoveling, high workpiece consistency, avoiding human error, one-time forming, and improving efficiency.

Contact Us

Fill out the form for professional support!

Why Choose Automatic Panel Bender Machine?

Efficient

The automatic steel bending machine can realize fully automatic and fast production. The bending speed is 3 times that of the CNC bending machine. The full servo control can make the product accuracy higher and greatly improve production efficiency.

Flexible

The flexible bending center can adapt to changing product needs and can handle multiple workpieces of different shapes, sizes, and batches at the same time. The modular design allows the bending machine to adapt to the company's needs.

Accuracy

The automatic panel bender machine is equipped with an intelligent control system, which can adapt to different sizes of metal plates, and can continuously produce parts of different sizes without manual adjustment. In addition, the automated parts processing system further shortens the cycle time, making this machine an ideal solution for short-term and long-term production.

Offline Programming

Using graphical visualization programming, you only need to input bending data, and the system can automatically generate bending instructions without the need for cumbersome code programming. The automatic panel bender machine can reduce machine downtime while ensuring user safety and eliminating any potential human errors.

Applications of Automatic Sheet Metal Bending Machine

The automatic panel bending machine is a highly automated and programmable sheet metal processing equipment that can realize bending of various angles and shapes without changing molds.

Frequently Asked Questions

An automatic bending machine is an intelligent device that can automatically position and bend, helping enterprises achieve high-efficiency and high-precision batch bending.

The panel bender does not need a mold and can bend various complex shapes; the equipment is equipped with a pure electric servo system, replacing hydraulic drive, and has the advantages of environmental protection, fast speed, high precision, and maintenance-free.

What does a metal sheet bending machine do?

The automatic sheet bending machine can realize multi-angle bending of various shapes and sizes, and these functions can be realized through a set of molds.

The XTLASER panel bending machine is equipped with an automatic programming system, which can automatically generate bending programs according to product drawings, reduce manual intervention, and improve processing accuracy and efficiency.

In addition, the automatic bending machine can process various metal plates, such as stainless steel, carbon steel, aluminum alloy, etc., to adapt to the bending characteristics of different materials.

Compared with traditional bending methods, the automatic panel bender machine has the following advantages:

- High safety factor

The automatic bending machine is controlled by a full servo, which can automatically change direction and calibrate, making it safer and more stable. The traditional manual operation bending machine needs to manually orient the metal plate, especially for large and heavy metal plates, which often require multiple people to move, which has a certain degree of uncontrollability and safety risks.

- Fast bending speed

The CNC bending machine needs to manually adjust the direction before bending, which is a waste of manpower. The automatic metal bending machine reduces the cycle time of multilateral and multi-pass bending, and can reach 0.2s/bending, which is 3 times the bending speed of the CNC bending machine.

The gradual replacement of traditional bending machines by automatic sheet metal bending machines is multifaceted. It not only has significant advantages at the technical level but also can better meet market demand, improve production efficiency, and reduce production costs.

The price of an automatic bending machine is generally from tens of thousands of US dollars to hundreds of thousands of US dollars, and the specific price depends on the configuration and functions of the machine.

The price of traditional bending machines will be much cheaper, generally between a few thousand US dollars and tens of thousands of US dollars. But there are still many customers who choose automatic bender machines. Why is this?

When an enterprise has batch production needs, such as file cabinets, electrical cabinets, etc., there may be hundreds of workpieces of the same specification. The automatic bender machine is the best choice. This is because the automatic bending machine has the advantages of high automation level, fast bending speed, low technical requirements, high safety, and strong bending consistency, which are better than traditional bending machines in any respect.

Although the traditional bending machine is cheap, the labor cost is high. However, in the long run, the cost of the automatic panel bending machine is lower. This is because the automatic bending machine is a one-time investment. With the increase in order volume and the decrease in labor costs, the cost of the automatic bending machine will be gradually weakened.

We know that customers purchase XTLASER's equipment because of trust, and perfect after-sales service and technical support are essential to your production and operation.

Our after-sales service includes comprehensive operation training, a 2-year warranty service for the whole machine, regular equipment maintenance, and perfect spare parts supply. These can ensure the normal use of the machine so as to create more value for your business.

In addition, we provide timely technical support, including various forms of technical support, remote assistance, free software upgrades, etc., so that your machine can always be up-to-date and keep up with market development and needs.

XTLASER promises to respond within 24 hours after receiving your service request. A professional technical team will provide you with efficient and professional services, always guided by your needs, and thoroughly solve your problems.

Other Products

- Laser Cutting Machine

KF-series Four-head Laser Cutting Machine

- Automation Equipment

TF-series 3D Five-Axis Laser Cutting Machine

- Laser Cutting Machine

XT LASER 4000w fiber laser cutting machine for sale