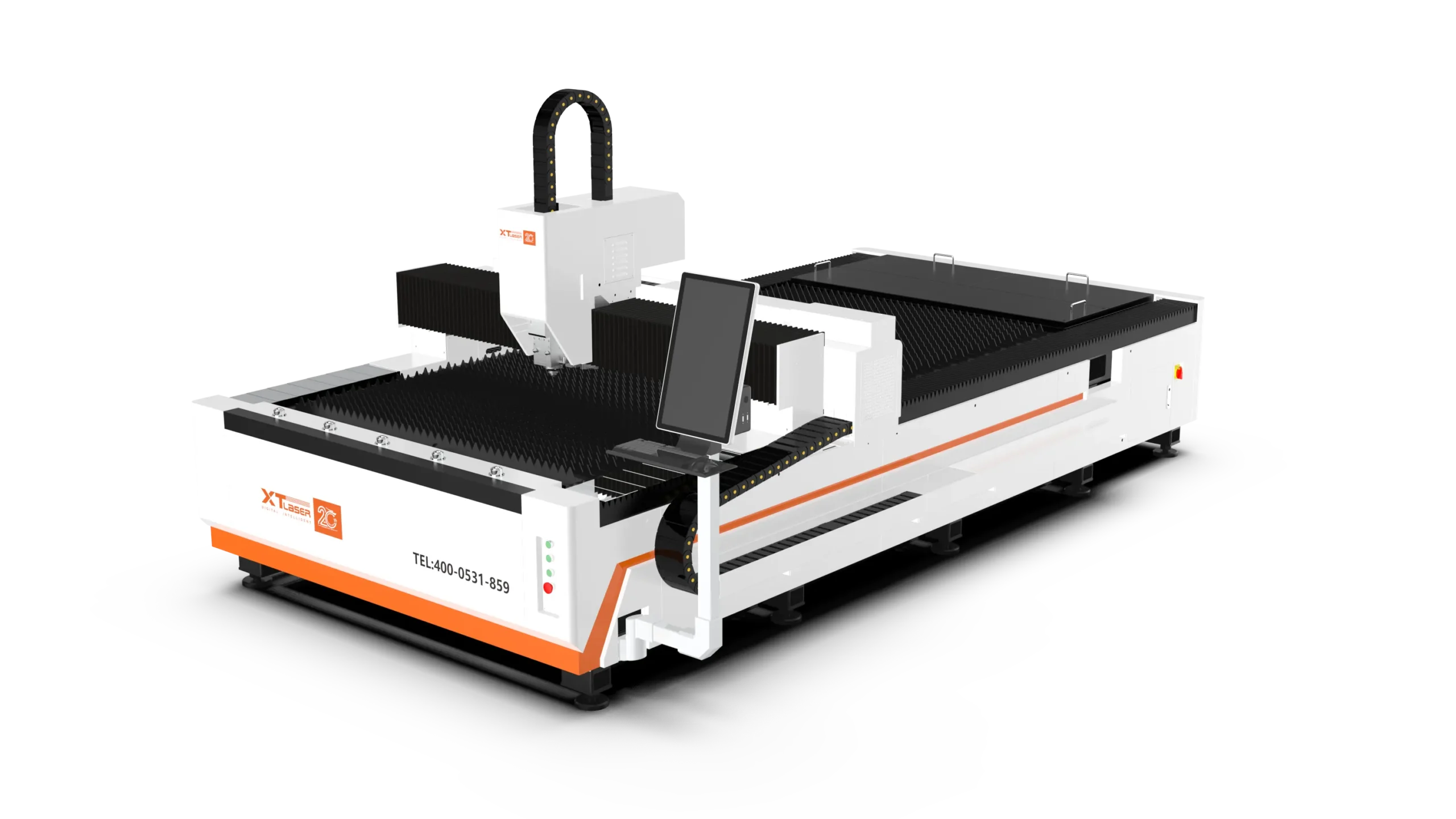

6000W fiber laser cutting machine Details

6000W high performance laser

- Adopting international famous brand (such as IPG, Raycus) 6000W/6kw fiber laser cutting machine fiber laser to ensure stable output power, high beam quality and long service life, which is the core component of best fiber laser cutting machine.

- The laser is equipped with automatic power adjustment function, which can automatically adjust the laser output power according to different materials and thickness to realize the best cutting effect.

- Equipped with high efficient cooling system to ensure the laser work stably for a long time and reduce laser metal cutting machine cost.

Intelligent auto-focus cutting head

- Adopting high-precision auto-focus cutting head, it can automatically adjust the focus according to the thickness of the plate and cutting requirements to realize the best cutting effect, which is an important symbol of professional laser cutting machine.

- The cutting head is equipped with anti-collision function, which effectively prevents the cutting head from colliding with the plate and causing damage.

- A variety of cutting nozzles are available to meet the needs of different materials and cutting processes.

High precision motion control system

- Adopt high-performance servo motor and driver to ensure cnc laser cutting machine for metal running smoothly, quickly and accurately.

- Equipped with high-precision rack and pinion transmission system to ensure transmission precision and efficiency, making this 6000w fiber laser cutting machine the best cnc fiber laser cutting machine.

- Adopt advanced motion control algorithm to optimize cutting path, improve cutting efficiency and reduce laser metal cutting machine cost.

Integrated welding bed

- Adopting whole welded structure, tempering treatment and vibration aging to eliminate internal stress, ensuring the stability of the bed without deformation, providing a solid foundation for professional laser cutting machine.

- The bed is precision machined to ensure the accuracy of guide rail installation and improve the running accuracy of 6000w fiber laser cutting machine.

High precision linear guide rail

- Adopting international famous brand (such as HIWIN, PMI) high-precision linear guide rail to ensure cnc laser cutting machine for metal running smoothly, high precision and long life.

- The guide rail is equipped with automatic lubrication system, which reduces the friction loss, prolongs the service life and reduces the laser metal cutting machine cost.

Humanized operation control system

- Adopting professional laser cutting control software based on Windows operating system, with friendly interface and easy-to-learn operation, even a novice can easily operate this 6000w fiber laser cutting machine.

- The software supports a variety of graphic formats import, graphic editing and layout, convenient and fast.

- Equipped with a 15-inch touch screen, the operation is convenient and intuitive.

Rich optional auxiliary configurations

- Equipped with double exchange table, which can realize the quick loading and unloading of boards and improve the production efficiency.

- Optional automatic loading and unloading system to realize automatic production, further enhance the efficiency of professional laser cutting machine.

- Equipped with smoke and dust removal system to effectively purify the working environment.

- Optional gas-assisted cutting system to improve cutting quality and efficiency.

All-around safety protection measures

- Equipped with a fully enclosed protective cover, effectively preventing the laser radiation and cutting splashes from causing injury to the operator.

- Equipped with safety interlocking device to ensure safe operation.

Excellent cutting precision and efficiency

- Repeat positioning accuracy is up to ±0.02mm, which ensures the cutting accuracy and consistency of the best fiber laser cutting machine.

- Cutting speed can reach up to 120m/min, significantly improving production efficiency.

Industrial grade quality assurance

- The whole machine adopts industrial grade components to ensure the stable operation of industrial fiber laser cutting machine for a long time.

- The key components are strictly tested and inspected to ensure the reliability of 6000w fiber laser cutting machine.

Individualized requirements

- We provide customized service, we can customize the table size, laser power, automation level, etc. of 6000w fiber laser cutting machine according to customer’s specific requirements.

- We can also provide professional cutting process solutions according to customers’ specific applications, such as fitness equipment laser cutting machine production.

Timely response and professional service

- We provide 24-hour online technical support to respond to customers’ service needs in a timely manner.

- Our service engineers will arrive at the site within 24 hours to solve the problem for customers.

Free operating manuals and tutorials

- We provide detailed 6000w fiber laser cutting machine operation manuals and video tutorials to help customers quickly master the operation of the machine.

- We also offer free online training courses to help customers improve their machine operation skills.

Remote diagnostics and maintenance

- XT LASER 6000w fiber laser cutting machine supports remote diagnosis and maintenance function, which can solve the machine faults remotely through the network.

- This can help customers save time and cost, and improve the efficiency of the machine.

Free software upgrades

- We provide free software upgrade service to ensure that customers always use the latest software version.

- We regularly release new software versions with new features and improved performance.

Adequate spare parts, fast supply

- We have sufficient spare parts in stock to provide customers with the required spare parts in a timely manner.

- We guarantee the quality and price of spare parts, so that our customers have no worries.

Professional laser cutting process support

- Our engineers have rich experience in laser cutting process and can provide professional process support for customers.

- We can help customers optimize cutting parameters to improve cutting quality and efficiency.

Coverage of multi-industry applications

- We have rich experience in industry applications and can provide professional solutions for our customers.

- The customers we serve cover a wide range of industries such as sheet metal processing, machinery manufacturing, aerospace, automotive manufacturing and so on.

Continuous technological innovation

- We continue to carry out technological innovation to continuously improve the performance and quality of 6000w fiber laser cutting machine.

- We cooperate with famous universities and research institutes at home and abroad to carry out cutting-edge technology research.

Environmental protection and energy saving

- Our industrial fiber laser cutting machine adopts environmentally friendly and energy saving technology to reduce energy consumption and environmental pollution.

- We are committed to providing customers with green laser cutting solutions.

Contact Us

Five-year Warranty

XTLASER knows that the stable operation of fiber laser cutting machines is very important to your production. In order to ensure the normal operation of the equipment, we provide a five-year warranty service, which is far higher than the average warranty level in the same industry. During the warranty period, as long as there is equipment failure caused by non-human factors, you will enjoy our 5-year warranty policy to ensure that your equipment is always in the best working condition. We are full of confidence in the quality of the machine and strive for excellence in every process. The parts and important accessories of each machine have been strictly screened and precisely assembled, and have undergone multiple proofreading and testing in the production and manufacturing process. Choose XTLASER, you get not only a fiber laser cutting machine but also a long-term peace of mind guarantee.

Remote Technical Support

In the process of using the machine, it is inevitable to encounter various operation problems. To enable you to obtain professional and timely technical support at any time, XTLASER will provide you with a 7×24-hour remote technical support service. Wherever you are, if you encounter any problems, you can contact us by any means, such as telephone, email, online chat, etc. Whenever and wherever our technical team will respond immediately and provide you with practical and feasible solutions.

Professional Training

Buy our 12kw fiber laser cutting machine, you will get professional training. We have comprehensive machine training tutorials, including equipment user manual, software user tutorial, maintenance manual, troubleshooting list, and other aspects. Whether you are a beginner of laser cutting machines or a skilled operator who wants to improve your skills, our training is beneficial. We will provide you with one-on-one guidance and patiently answer your questions in the process of use so that you can quickly master the use skills of the machine.

Global Customer Return Visit

Customer satisfaction is our greatest motivation. XTLASER conducts global return visits every year, visits customers regularly, understands customers' needs, and answers questions encountered in the process of using the machine. We value your every suggestion and make improvements after careful discussion. We will carefully analyze your usage feedback, continuously optimize product design, and improve service quality. Choose XTLASER, you will become a witness and participant in the continuous improvement of our fiber laser cutting machine and service.

Frequently Asked Questions

With its powerful power and advanced laser technology, 6000W fiber laser cutting machine can efficiently cut a variety of metal materials, covering almost all common metal types. Below are the specific materials that can be cut and their maximum cutting thickness:

- Carbon Steel: As the most widely used metal material in industrial applications, carbon steel can be cut up to a thickness of 30mm, and both thin and thick plates can be cut at high speeds and with high precision to meet a variety of processing needs.

- Stainless Steel: Due to its excellent corrosion resistance and aesthetics, stainless steel is widely used in food processing, medical equipment, building decoration and other fields. Our machines can cut stainless steel sheets up to 25mm in thickness with smooth edges and without secondary processing.

- Aluminum: With its lightweight, high strength and easy processing, aluminum alloys are widely used in aerospace, automotive and electronics industries. Our machines can cut aluminum alloys up to 20mm in thickness, with high cutting speed and precision, to meet the processing needs of complex parts.

- Copper: Copper has good electrical and thermal conductivity and is commonly used in the electrical, electronics and telecommunications industries. Our machines can cut copper plates up to 12mm in thickness, with stable cutting process and high precision to meet the processing requirements of precision parts.

- Brass: As an alloy of copper and zinc, brass has good mechanical properties and corrosion resistance, and is commonly used in machinery manufacturing, instrumentation and other fields. Our machines can efficiently cut brass sheets of various specifications with excellent cutting quality.

- Galvanized Sheet: Galvanized sheet has good corrosion resistance and is widely used in construction, automobile, home appliance and other industries. Our machines can cut galvanized sheet of various thicknesses with high cutting speed and efficiency to meet the needs of mass production.

In addition to the metal materials listed above, our 6000W fiber laser cutting machine can also cut a variety of other metal materials, such as:

- Titanium alloy: used in aerospace, medical equipment and other high-tech fields.

- Nickel alloys: for special applications in high-temperature, highly corrosive environments.

- Alloy steels: used to make high-strength, wear-resistant mechanical parts.

If you need to cut other metal materials not listed, welcome to consult our technical staff, we will provide professional advice and solutions according to your specific needs.

We are confident in the quality of our products and offer an industry-leading warranty to give you peace of mind:

- 3 Years Warranty: Covers all components and systems of the machine, including the laser, cutting head, motion control system, bed, guide rails, operator control system, auxiliary configurations and more. During the warranty period, if the machine has any quality problems, we will provide free repair or replacement services.

- 5-year laser warranty: As the core component of the machine, we provide up to 5-year warranty service to fully protect your investment. During the warranty period, if any quality problem occurs with the laser, we will provide free repair or replacement service.

- Our warranty service reflects our commitment to the quality of our products and our responsible attitude towards our customers. We believe that with high quality products and perfect after-sales service, we are able to win your trust and establish a long-term cooperative relationship with you.

We provide many convenient ways to get a quote for 6000w laser cutting machine, you can choose the one that suits you best to contact us:

- Online Inquiry: You can use the online inquiry tool on our website to communicate with our sales staff directly and get real-time quotes.

- Telephone: You can call our customer service hotline, our sales staff will be happy to serve you and provide you with detailed quotation information according to your needs.

- Email: You can send your requirements to our email, we will reply to your email as soon as possible and provide the corresponding quotation program.

- Submit RFQ: You can fill in the RFQ form on our website, describing your requirements in detail, including cutting material, thickness, precision requirements, automation level, etc. We will provide you with detailed quotation information based on the information you provide. We will customize a quote for you based on the information you provide.

In order to provide you with the most accurate quotation, please describe your needs in as much detail as possible, for example:

The type and thickness of material you need to cut

Your requirements for cutting accuracy and speed

Whether you need an automated loading and unloading system

Your desired delivery time

We promise to reply you within 24 hours and offer competitive price.

We understand that lead times are important to you, so we are committed to delivering your machine as quickly as possible. Typically, our lead time is 4-6 weeks.

The exact lead time depends on the following factors:

- Machine Configuration: If you have chosen a complex machine configuration, such as customized table sizes, additional automation modules, etc., the lead time may be slightly longer.

- Order quantity: If you order a large number of machines, the delivery time will be longer.

- Production schedule: Our production schedule is dynamically adjusted according to the order situation, so the delivery time will also be affected by the production schedule.

In order to ensure that you receive your machine in time, we will confirm the exact delivery time with you after you place your order and update you on the production progress in a timely manner. We will also do our best to shorten the delivery time to meet your urgent needs.

If you have any questions about delivery times, please feel free to contact us.

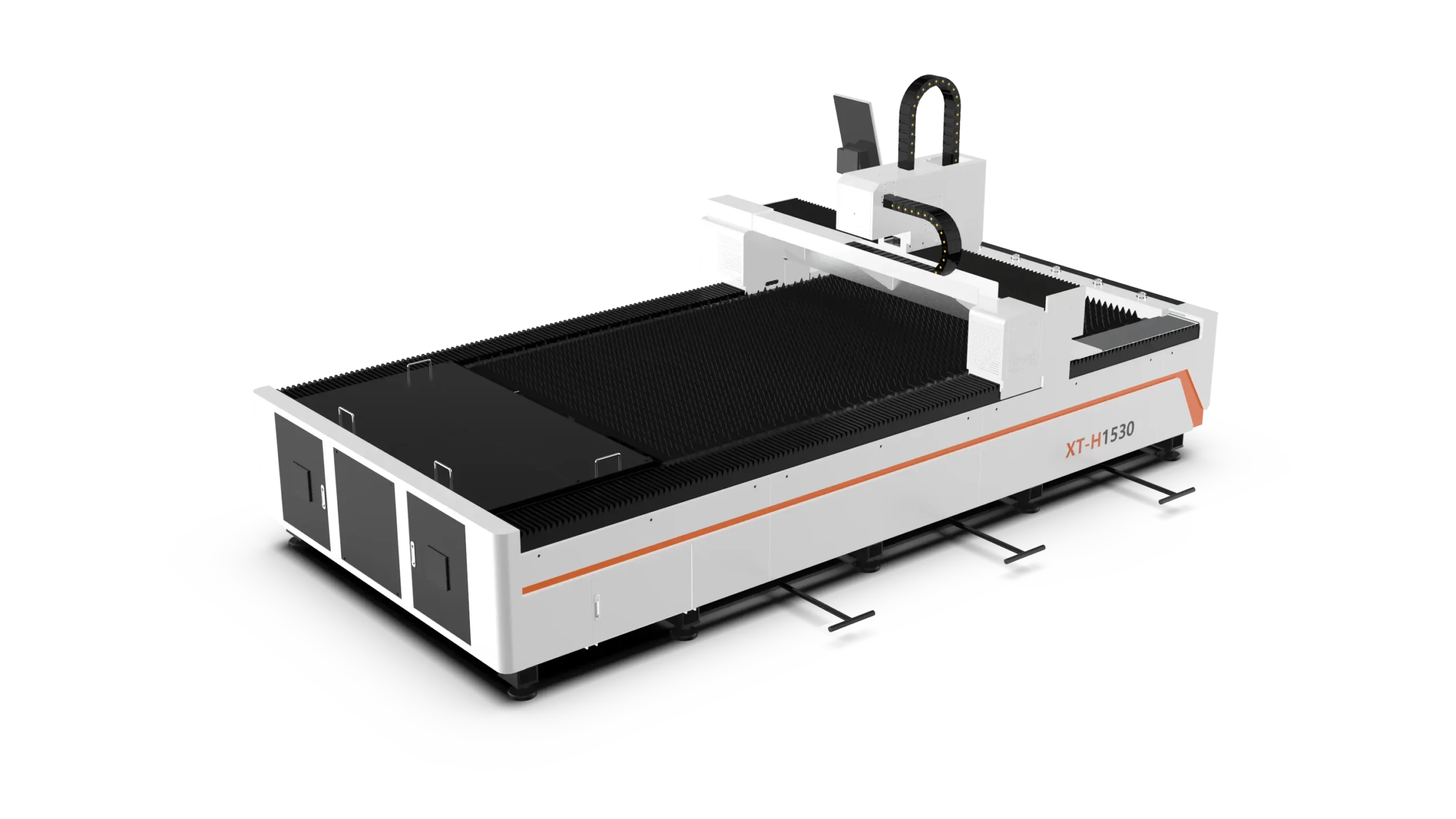

Releated Products

Related products

- Laser Cutting Machine

HR Series H Beam Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

W-series Single Table Fiber Laser Cutting Machine

- Sheet Metal Laser Cutting Machine

H-series Open Type Fiber Laser Cutting Machine

- High Power Laser Cutting Machine

GP-Series High Power Laser Cutting Machine