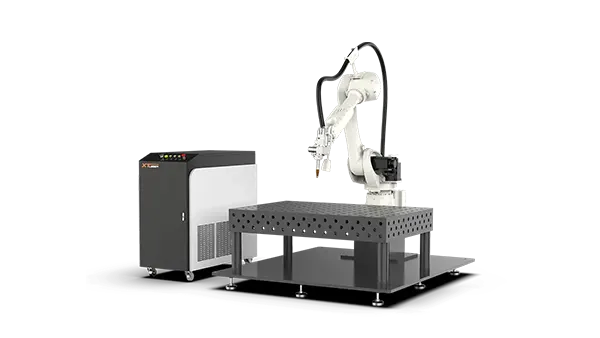

6-Axis Automatic Robotic Laser Welding Machine

Model – Robot Laser Welding Machine

Brand – XTlaser

Laser Power – 1500W, 2000W, 3000W are optional, expandable to 12000W on request

Welding Depth – 4mm / 5mm / 6mm

XTLASER automatic robotic laser welding machine reacts sensitively and accurately, and cooperates effectively with the laser to make the effect of each welding point consistent after transmission through the optical fiber. Robot laser welding machine power can be extended up to 12000W to meet the welding of thick plates and online flight welding.

XTlaser - Metal Robotic Laser Welding Machine Supplier

A robotic laser welding machine uses an industrial camera and laser scanner to get the information of the welding area. It moves the welding arc to the required position through the control system to realize automatic welding.

Compared with manual labor, robotic welding is characterized by high efficiency, high precision, and high stability. It is widely used in machinery manufacturing, the automotive industry, the food industry, and so on.

Automatic Laser Welding Machine Specifications

| Machine Model | 1500W | 2000W | 3000W |

|---|---|---|---|

| Conduction Type | Fiber Optics | ||

| Laser Wavelength | 1064nm | ||

| Cooling Mode | Water Cooling | ||

| Repeat Positioning Accuracy | ±0.04mm | ||

| Welding Mode | Dot/Circle/Line/8-Shape Mode, etc. | ||

| Spot Diameter (Of a Light Beam) | 0.1-6mm | ||

| Welding Depth | 4mm | 5mm | 6mm |

Robotic Laser Welding Machine Details

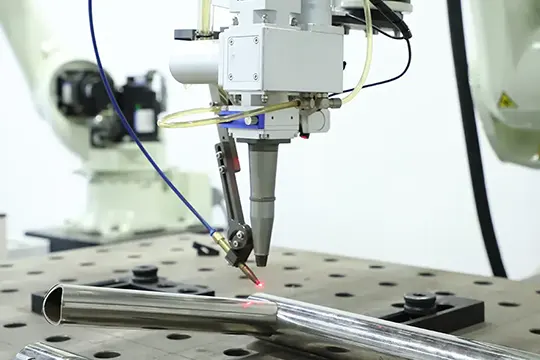

360° Welding Without Blind Area

- XTLASER robot laser welder is a 6-axis robot drive, which can change the welding angle according to the actual welding needs, realizing 360-degree welding without blind area.

- The 360-degree swivel function allows the welding robot to handle complex shapes and hard-to-reach areas, such as deep grooves and curved surfaces, thus ensuring comprehensive welding.

High Safety

- The 6-axis laser welding machine reduces the risk of direct operator exposure to high temperatures and harmful fumes.

- Through automation and remote control, the operator can monitor and operate from a safe distance, increasing the safety of the work environment.

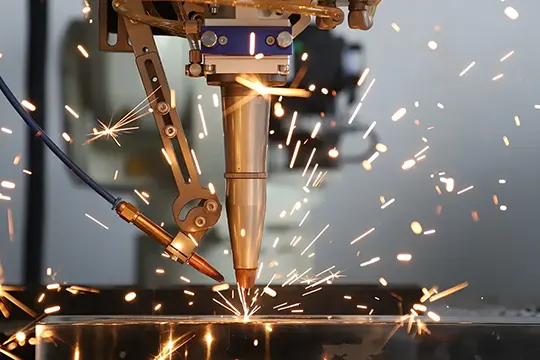

Welding a Wide Range of Materials and Processes

- Robotic laser welding machines are suitable for a wide range of materials, including stainless steel, carbon steel, aluminum alloys, and galvanized sheets.

- Robotic laser welding equipment can perform a variety of welding processes, such as fish scale welding, spot welding, and splicing welding.

Contact Us

Fill out the form for professional support!

Why Choose the XTlaser Handheld Welder Machine?

Superior Welding Precision

Our robotic welding machines utilize advanced laser technology and high-precision robot control systems to achieve ultra-high welding precision and speed.

Safety Guarantee

We emphasize operator safety, and our equipment is equipped with multiple safety measures, such as flashing light reminders and emergency stop buttons, to ensure that operators can quickly detect abnormalities in the equipment and safeguard their safety.

Professional Technical Support

XTlaser provides comprehensive and professional technical support for every buyer, including operation training, troubleshooting, after-sales service, equipment maintenance, etc.

Flexible Customized Solutions

We respect each customer's unique needs for a laser welder and therefore provide customized solutions, including equipment selection, different power requirements, and the size of the welding area.

Applications of Fiber Laser Welding Robot

Laser Robot Welding Machine Samples

The laser welding machine can weld square tubes, round tubes, sheet metal, and more.

Frequently Asked Questions

The laser welder price depends on the type of equipment, power, brand, etc.

The hand held laser welding machine price is about 4000-7000 US dollars, the desktop laser welding machine price is generally in the range of 10000-15000 US dollars, and the robot laser welding machine costs more than 20000 US dollars.

The price of hand held laser welding machine is about 4000-7000 US dollars, the price of a desktop laser welding machine is usually 10000-15000 US dollars, while a robot laser welding machine costs more than 20000 US dollars.

The degree of automation affects productivity and consistency, and robot laser welding machines can be paired with laser cutters, laser tube cutters, and automated loading and unloading systems to increase productivity. One automatic robot laser welder can replace 4 workers, which saves labor costs and greatly improves production speed.

There are several aspects to consider when choosing between the different types of laser welding machines:

- Depending on the application requirements

Tabletop laser welding machines are preferred for small workpieces that need to be welded with high precision.

If flexible and portable operation is required and the budget is low, a handheld laser welding machine is the best choice.

If high-volume production and a high degree of automation are required, choose a robotic laser welding machine.

- Depending on the budget

Handheld laser welding machines cost less and are suitable for small to medium-sized businesses and on-site operations.

Benchtop laser welding machines are moderately costly and suitable for applications where budget is limited but high precision is required.

Robotic laser welders are more costly but can significantly improve efficiency in mass production and are suitable for larger organizations.

Choosing the right laser welder requires comprehensive consideration of specific application needs and budget. Understanding the features and usage scenarios of each type of equipment can help you make a choice that meets your actual needs.

Releated Products

Related products

- Laser Welding Machine

Portable Handheld Laser Welding Machine

- Laser Welding Machine

Automatic Tabletop Laser Welding Machine