Products

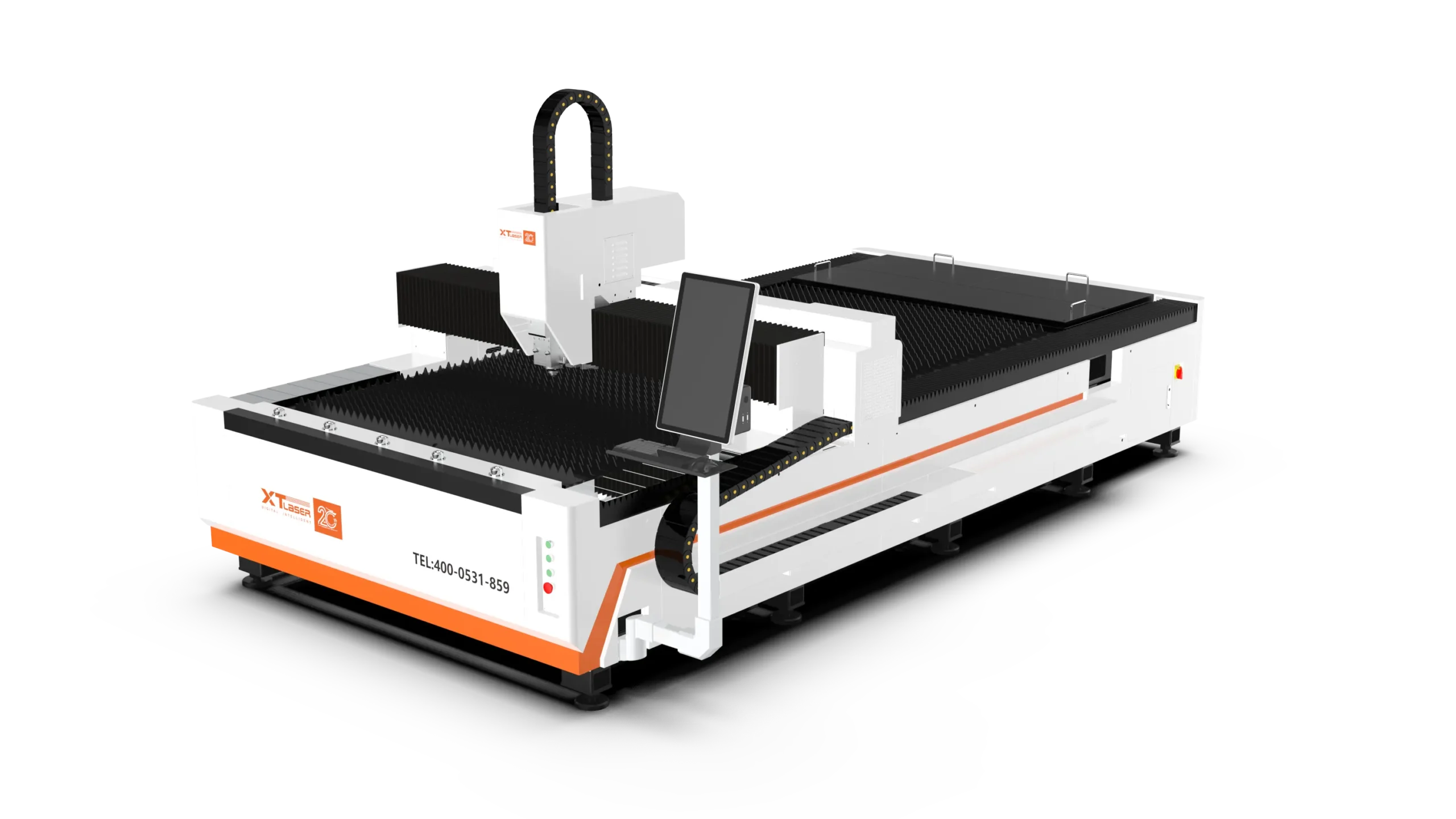

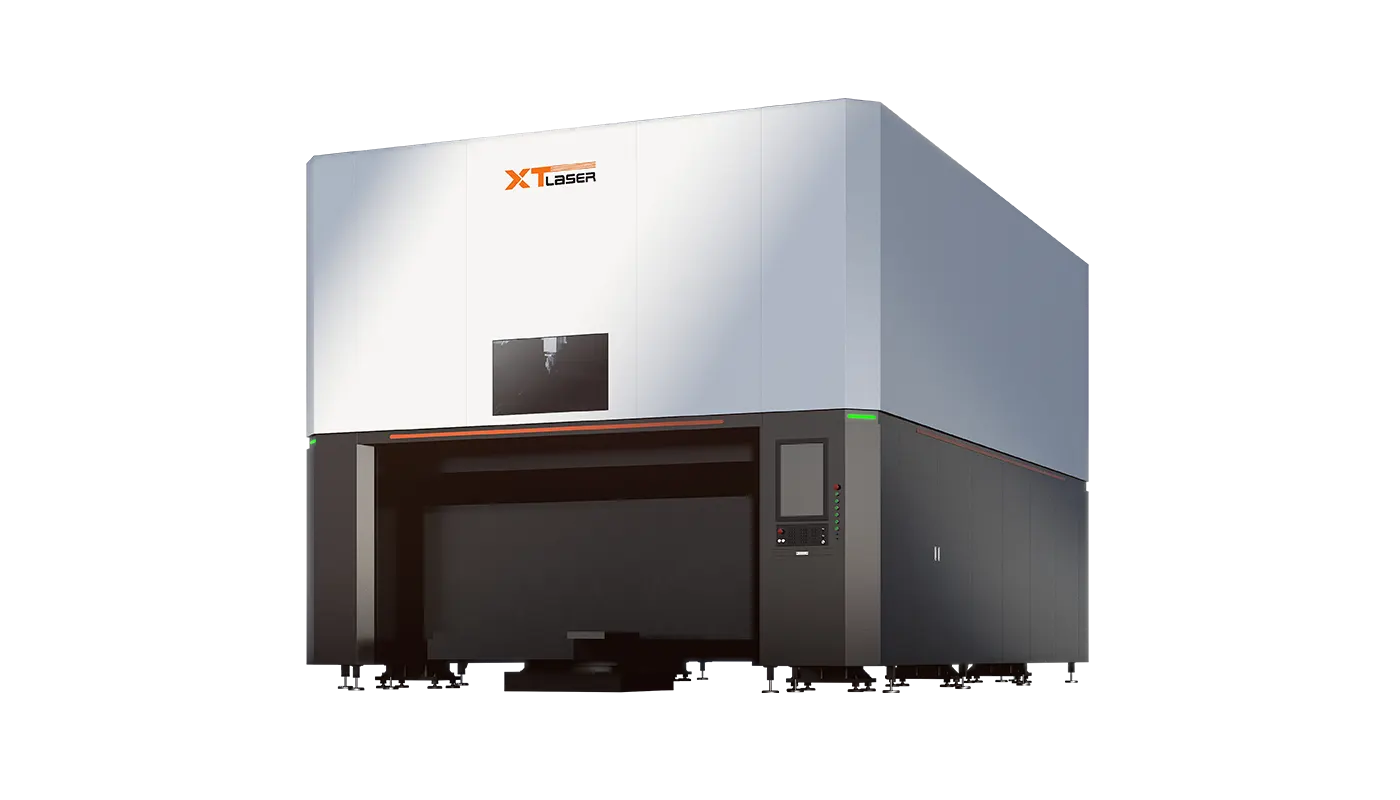

Sheet Metal Fiber Laser Cutting Machine >>

- 1

- 2

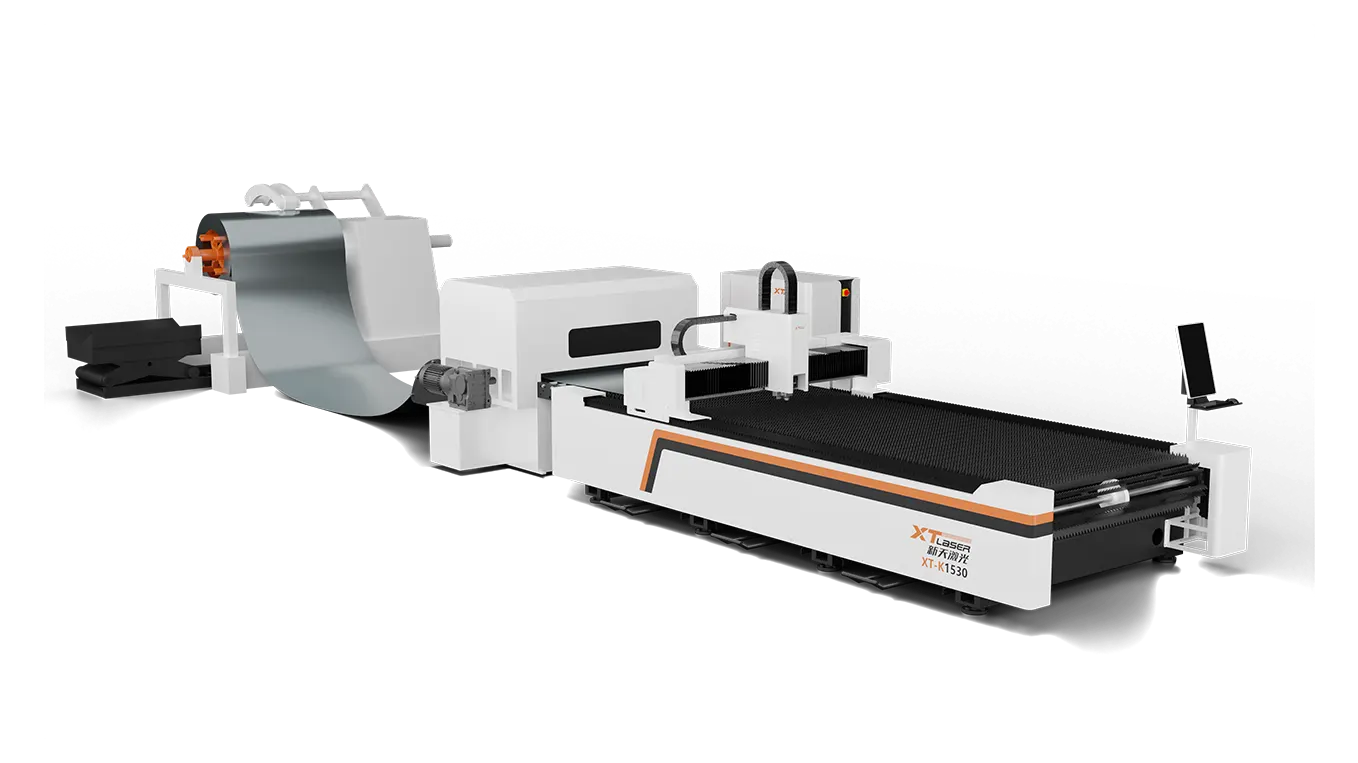

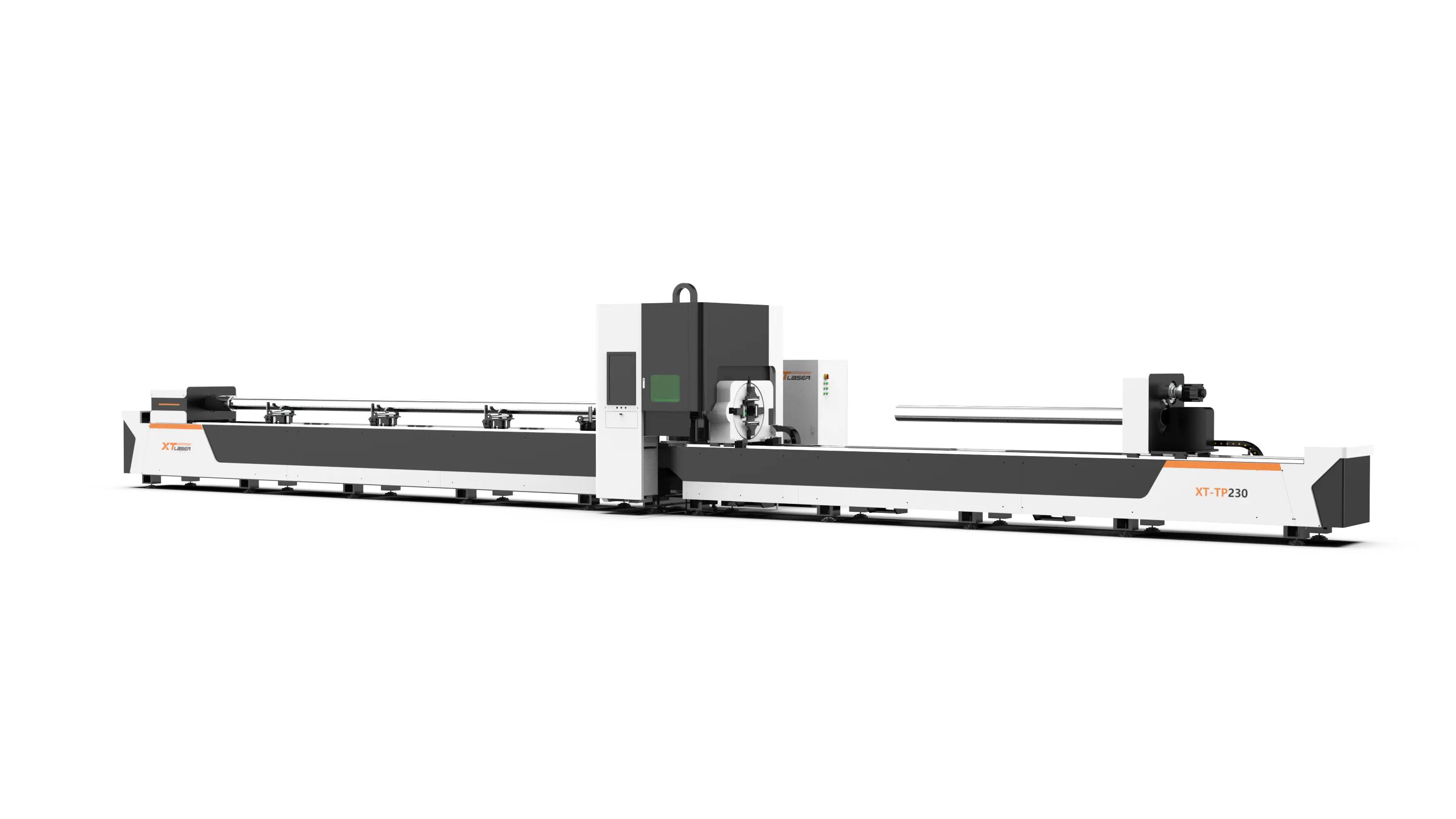

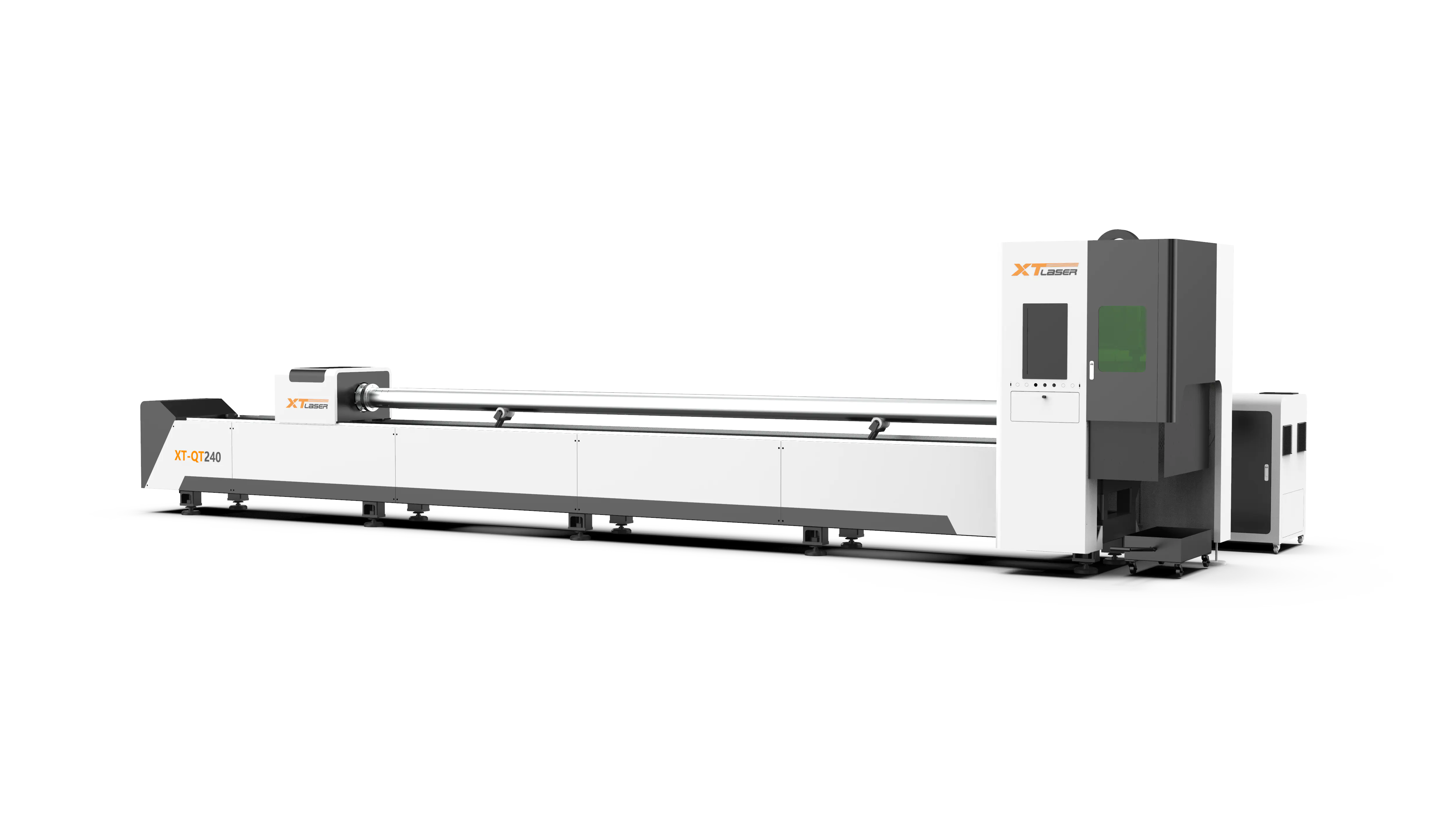

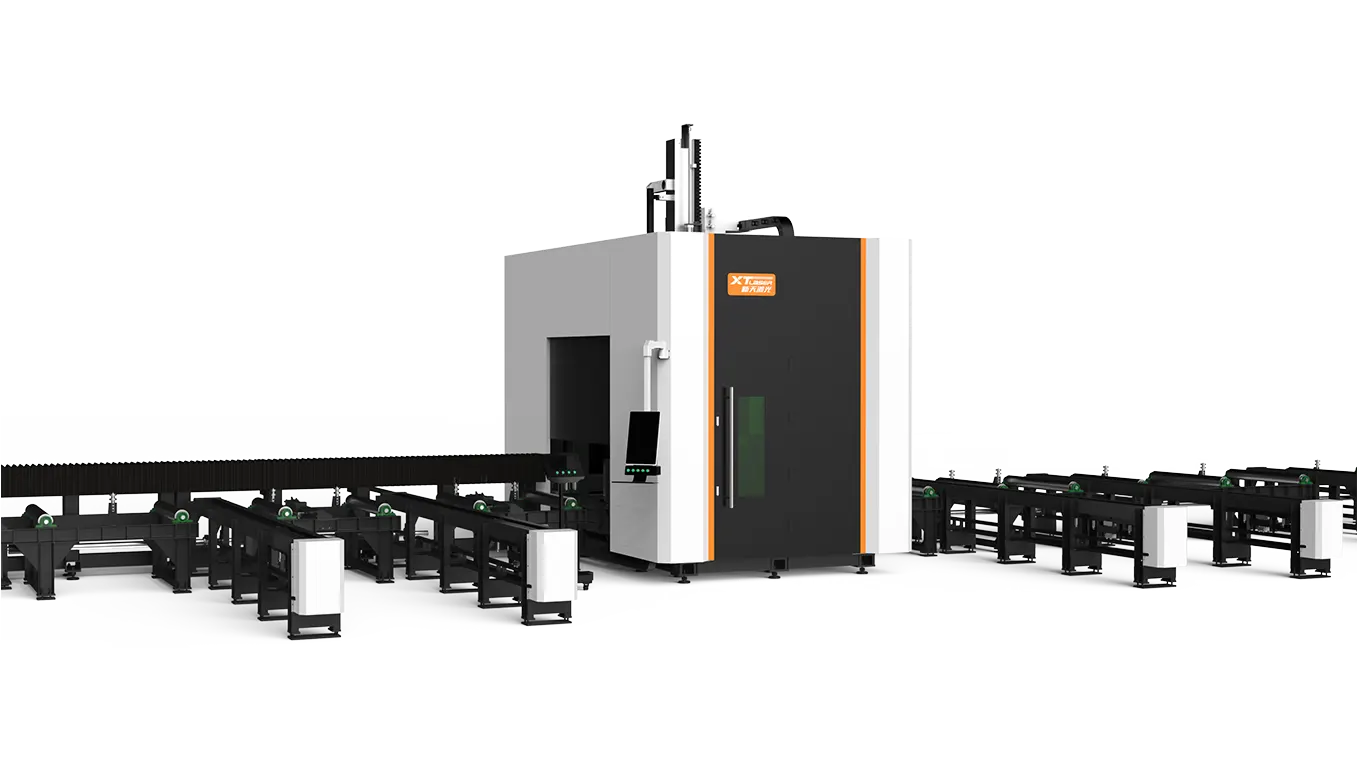

Plates and Pipes Laser Cutting Machine >>

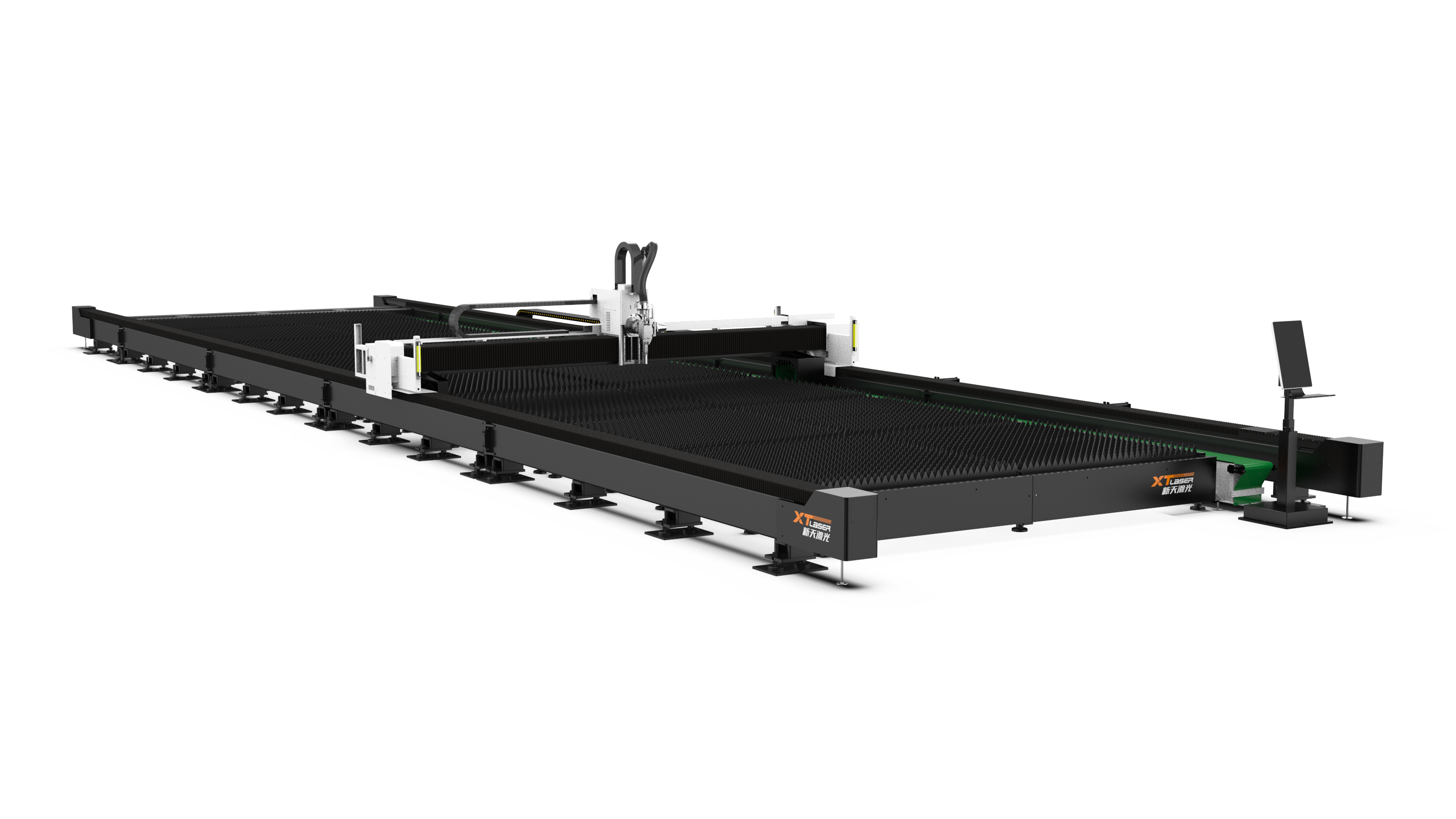

Large Format Laser Cutting Machine >>

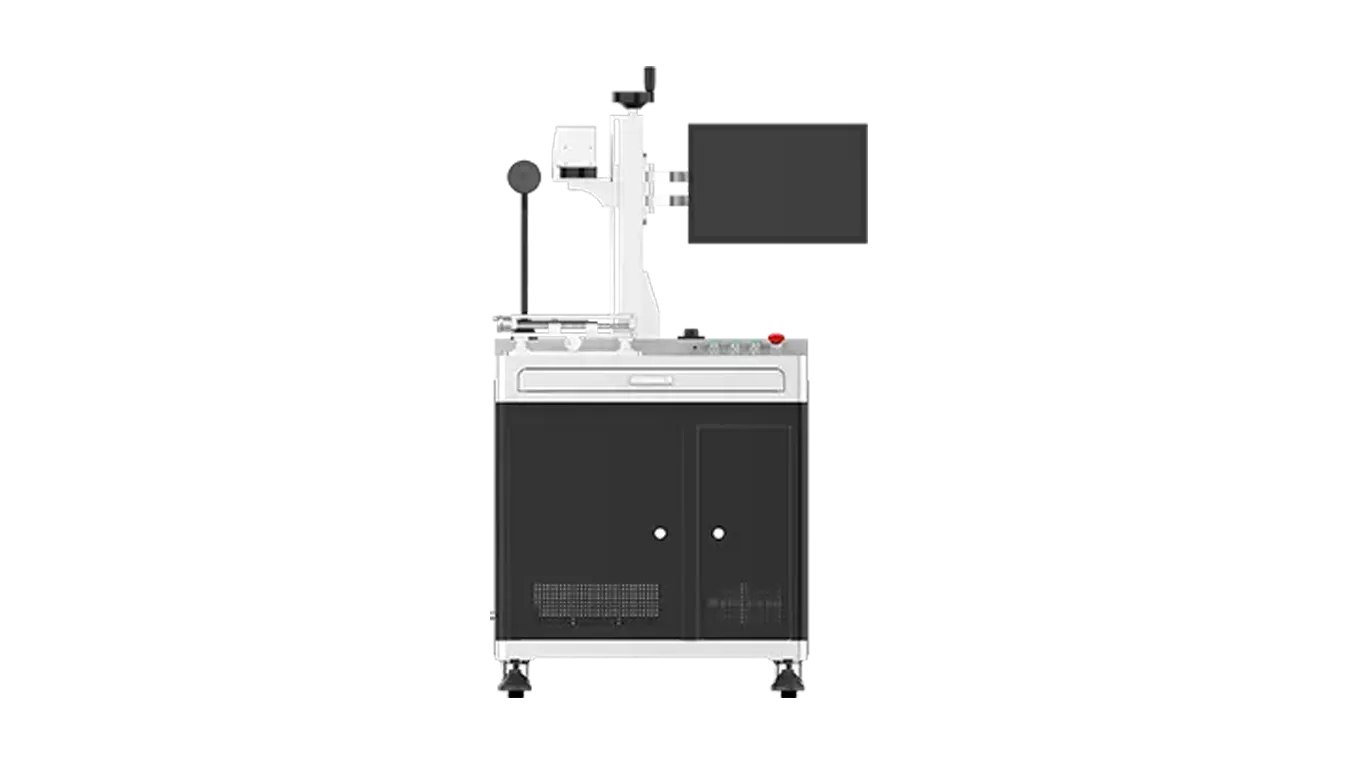

Laser Marking Machine >>

Laser Cleaning Machine >>

Five-year Warranty

XTLASER knows that the stable operation of fiber laser cutting machines is very important to your production. In order to ensure the normal operation of the equipment, we provide a five-year warranty service, which is far higher than the average warranty level in the same industry. During the warranty period, as long as there is equipment failure caused by non-human factors, you will enjoy our 5-year warranty policy to ensure that your equipment is always in the best working condition. We are full of confidence in the quality of the machine and strive for excellence in every process. The parts and important accessories of each machine have been strictly screened and precisely assembled, and have undergone multiple proofreading and testing in the production and manufacturing process. Choose XTLASER, you get not only a fiber laser cutting machine but also a long-term peace of mind guarantee.

Global Customer Return Visit

Customer satisfaction is our greatest motivation. XTLASER conducts global return visits every year, visits customers regularly, understands customers' needs, and answers questions encountered in the process of using the machine. We value your every suggestion and make improvements after careful discussion. We will carefully analyze your usage feedback, continuously optimize product design, and improve service quality. Choose XTLASER, you will become a witness and participant in the continuous improvement of our fiber laser cutting machine and service.

Laser Frequently Asked Questions

Fiber laser cutting machine can effectively cut different variants of metals which is inclusive of the following:

- Stainless steel

- Carbon steel

- Aluminum

- Brass

- Copper

- Galvanized steel

- Titanium

- Alloy steel

The materials that can be cut along with the maximum thickness of each depend on several factors, which include the laser power output and the material itself. Power output and the cutting material greatly influence the maximum depth to which cut can be made. A higher output power, a thicker material can be cut. For instance:

3kW laser cutting machine: It can cut through around 25mm of mild steel

6kW laser cutting machine: It can cut through approximately 35mm of mild steel

12kW laser cutting machine: It can cut through around 50mm of mild steel

XT LASER laser cutting machines are known for their high precision and excellent edge quality. Typical cutting accuracy can be as high as ±0.05mm, and the edge roughness can be as low as Ra 1.6µm or better. While the specific cutting values can vary depending on the material’s type thickness and cutting parameter as well.

Cutting speed is dependent on laser power, material, and thickness among others. Below is an estimate of mild steel cutting speeds for different material thicknesses using a 6kW fiber laser. To be more precise:

| Material Thickness (mm) | Cutting Speed (m/min) |

|---|---|

| 1 | 50 |

| 3 | 20 |

| 6 | 8 |

| 10 | 2.5 |

| 20 | 0.5 |

We have several laser power configurations that meet the requirements of various needs. The lifespan of the laser depends on the type and use, but overall it is very long. Many of the lasers we sell are covered by extended warranties:

Standard lasers: Usual 2 year warranty coverage.

High-power lasers (12kW and above): Frequently have a warranty of 5 years.

Certainly, many of our customers have benefitted from several promotional offers on such items as laser machines last cutting our company offers. You can get in touch with our sales personnel to get the benefit of understanding the pricing and other information like offers available.

Depending on the various models and customer`s requirements the marked area of our laser marking machines differ although there are standard which are 70 through to 300 mm. Larger marking areas obviously can also be catered for through machine customisation.

Marking speed depends on the laser's power as well as the marking complexity. Here's a rough perspective:

Desktop laser marking machine: Marking speed < 10000 mm/s

Portable laser marking machine: Marking speed < 6000 mm/s

Enclosed fiber laser marking machine: Marking speed 4000 mm/ s - 10000 mm/ s

They also include the following metals:

- Aluminum

- Copper

- Nickel alloys

- Titanium

The typical welding penetration depth is 3-5mm but can vary based on laser power and material properties.

Lasers achieve high welding accuracy as well as strong welds during laser welding. The maximum achievable accuracy is 0.05 mm. The strength of the weld is often equal or greater than the parent material. To understand if it satisfies your needs, please share a write up on your application and materials used.

Laser cleaning machines are handy in removing impurities from all types of materials specifically:

- Oxides

- Grease

- Oil

- Paint

- Coatings

- Rust

They are also ideal in cleaning metals, plastic, ceramics and composites. Laser cleaning is also best used for precision parts cleaning since it is a non-contact cleaning which will never damage or wear the primary material.

The maximum bending length that our automatic bending centers are able to manage is 1600mm.The maximum thickness that is bent in a material always depends on the material itself; Mildsteel up to 1.5mm, Stainless steel up to 1mm and Aluminum up to 2 mm. Special measures can also be taken into account for custom projects where we can bend thicker materials.