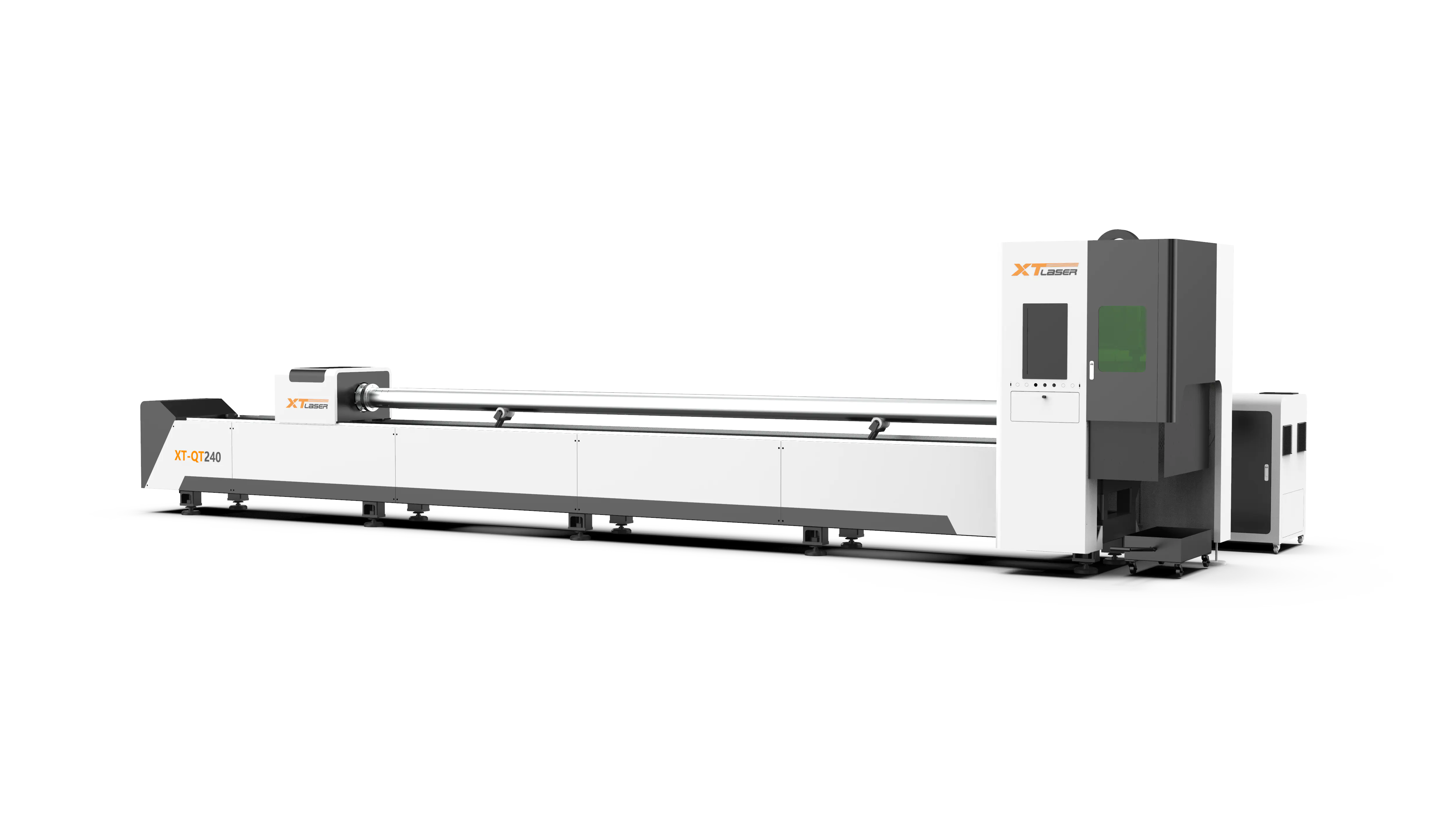

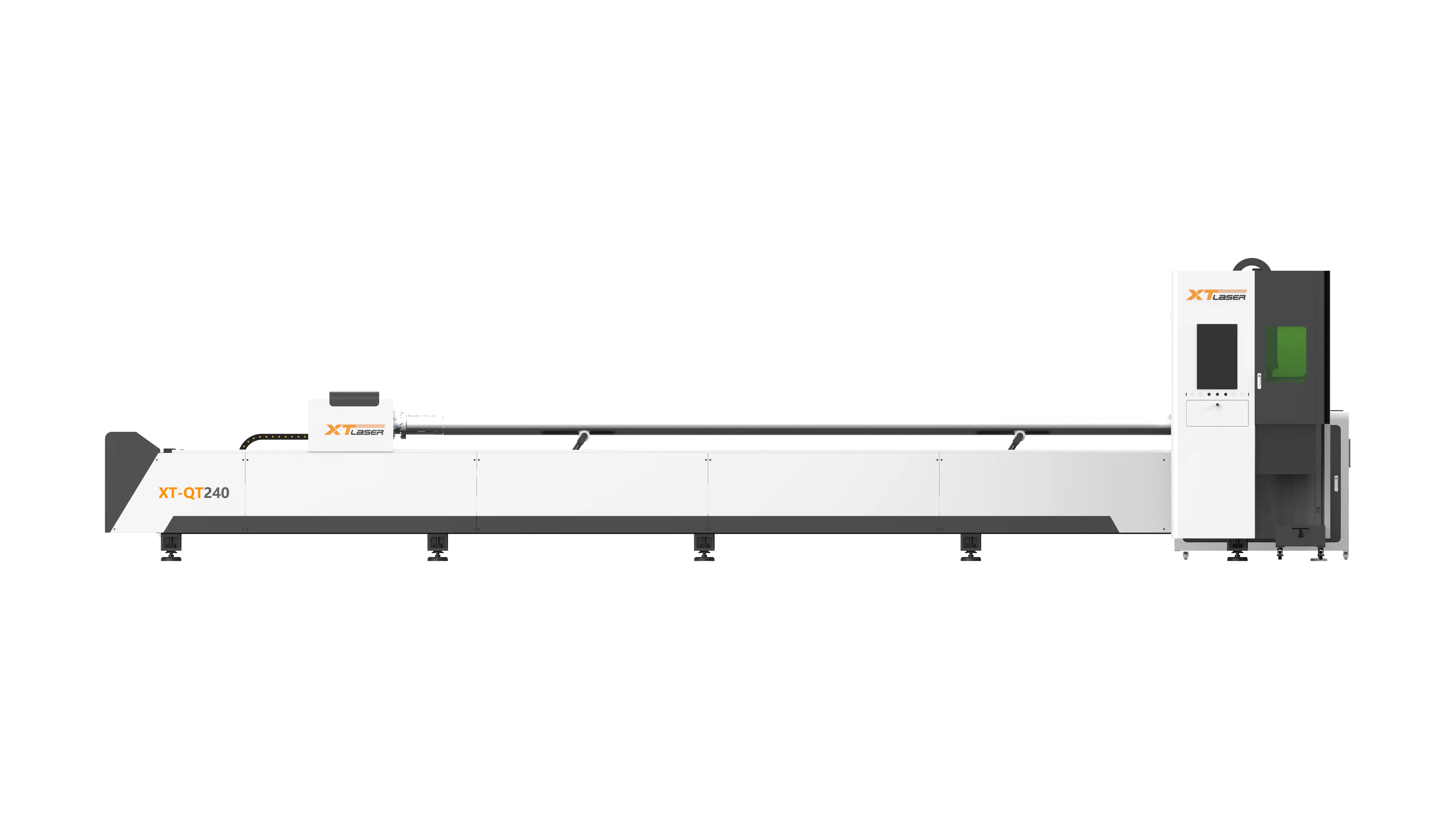

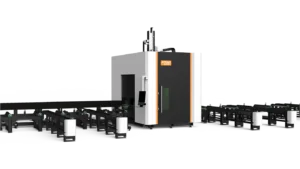

QT-series Tube Fiber Laser Cutting Machine

Model – T240

Brand – XTlaser

Clamping Range — φ10-240mm

(Can be customized according to customer requirements)

XTlaser QT-series CNC tube fiber laser cutting machine is equipped with a dedicated cutting operation system, which is easy to operate, highly accurate, and suitable for cutting metal profiles such as carbon steel, stainless steel, silicon steel, aluminum alloy, etc., including square tubes, round tubes, angle steel, channel steel, etc.

XTlaser-Best Laser Tube Cutter for Sale

From sports equipment to furniture manufacturing, and even to industries like oil pipelines and chemical equipment, laser tube cutting machines play an irreplaceable role.

XTlaser, with 20 years of experience in fiber laser equipment manufacturing, provides professional laser cutting solutions to customers in over 160 countries worldwide.

Continue reading to learn more about the Tube Fiber Laser Cutting Machine.

QT-series Laser Tube Laser Cutting Machine Specifications

| Machine Model | XT-T120 | XT-T160 | XT-T240 |

|---|---|---|---|

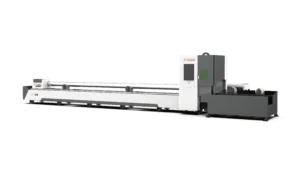

| Tube Length(mm) | 6.5m | ||

| Laser Power(W) | 1500W-4000W | ||

| Maximum Chuck Speed | 130r/min | ||

| Maximum Speed of Chuck Feed Axis | 125m/min | ||

| Maximum Acceleration | 1.5G | ||

| Clamping Range | φ 10-120mm | φ 10-160mm | φ 10-240mm |

| Position Accuracy | ±0.03mm/m | ||

| Processing Materials | Carbon steel pipes, stainless steel pipes, silicon steel pipes, aluminium alloy pipes and other metal pipes | ||

Xtlaser QT-Series CNC Tube Cutting Machine Features

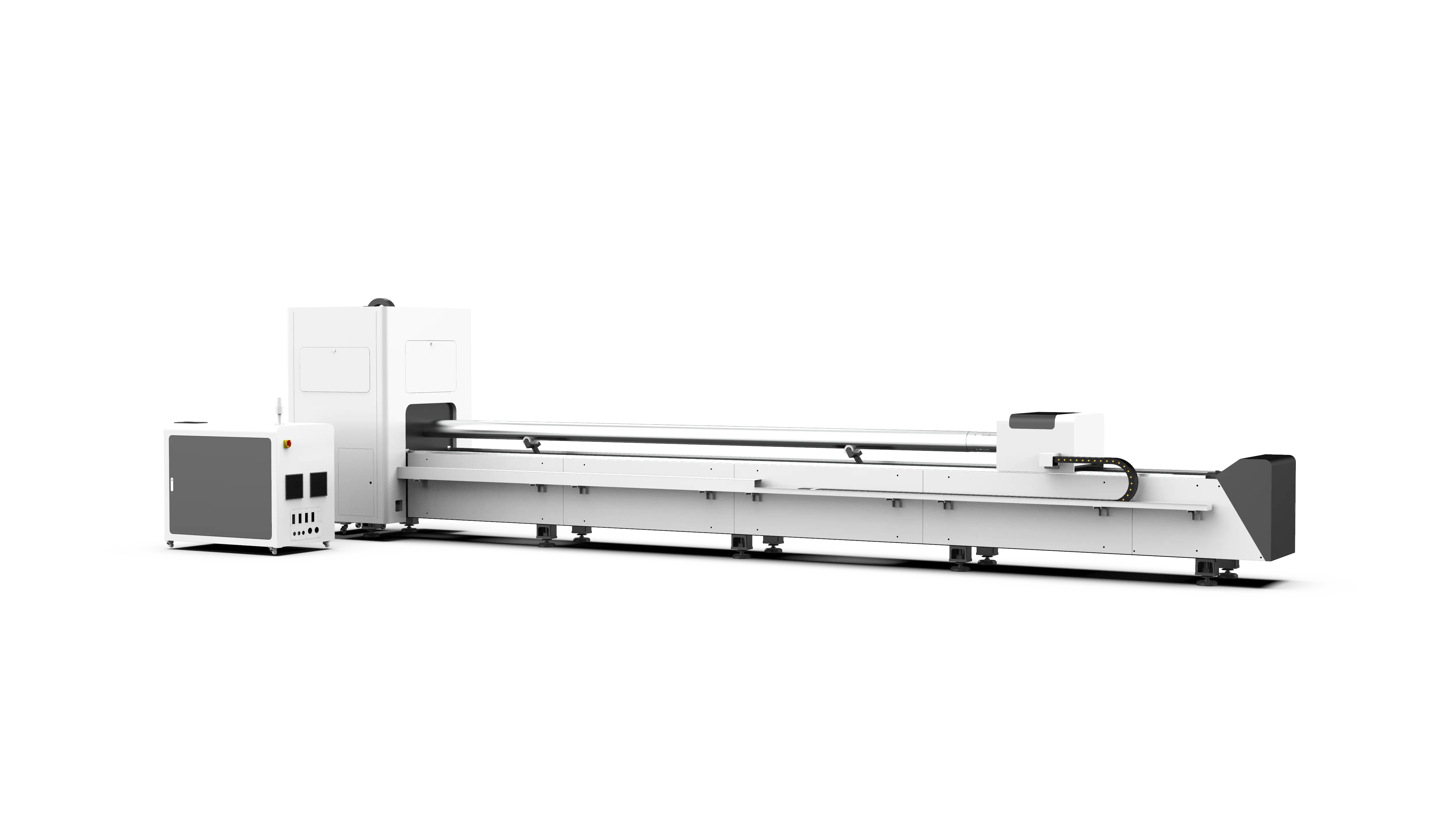

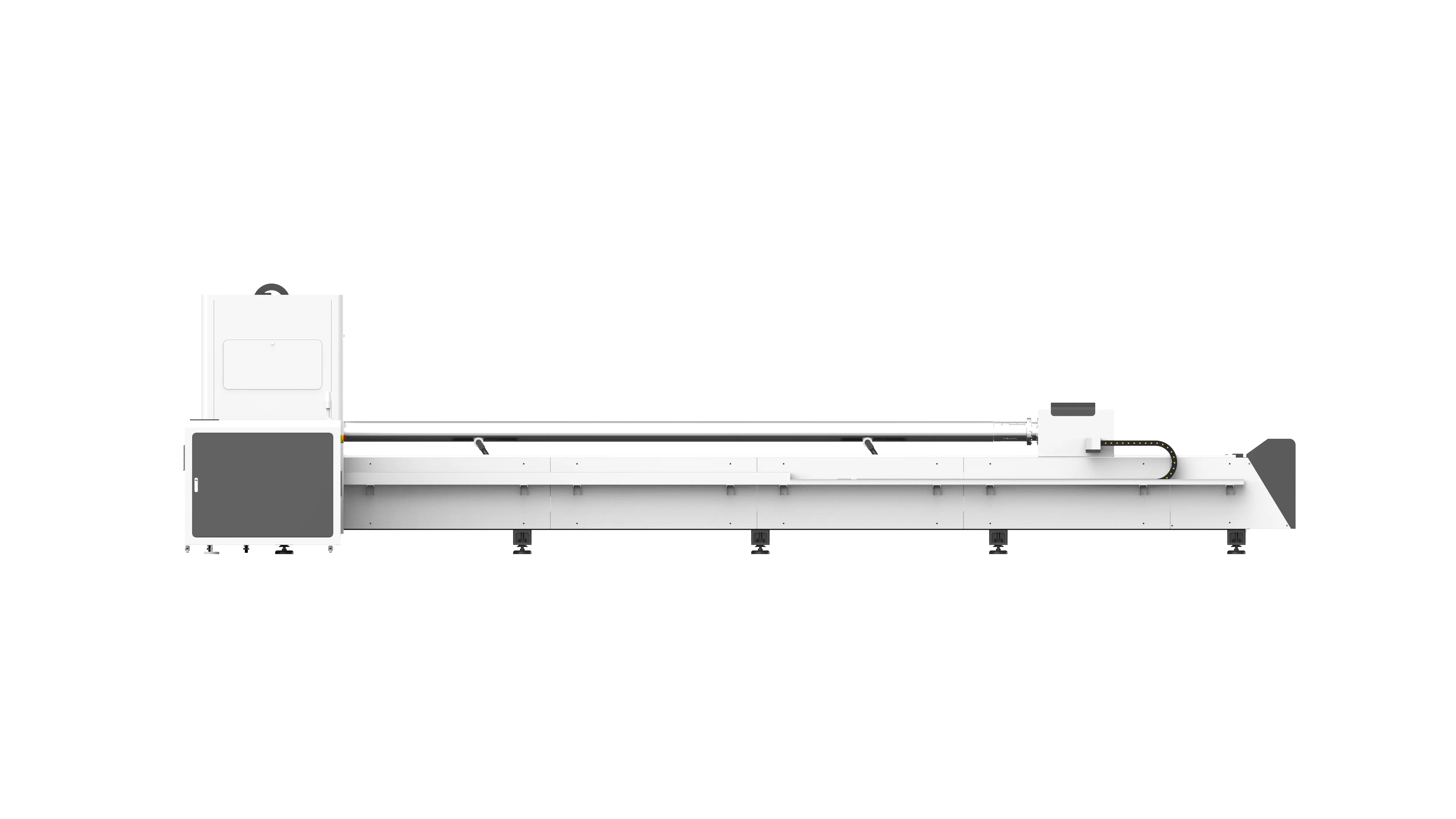

- The bed of the tube fiber laser cutting machine is welded from square tubes, tempered at high temperatures to relieve stress, with strong load-bearing capacity and good shock absorption performance.

- Dual precision pneumatic chucks enable rapid clamping of thin and thick tubes without deformation.

- Equipped with a dedicated cutting operation system, easy to operate, highly accurate, and with strong professionalism.

- The clamping range of the laser tube cutting machine can be customized according to customer requirements, with a maximum of up to 360mm.

- Equipped with dedicated support frames to lift metal tubes to prevent sagging deformation, improve cutting accuracy, and extend chuck life.

What Efforts Has XTlaser Made to Ensure the Quality?

XTlaser attaches great importance to the quality of laser cutting machines and has taken multiple measures and efforts to ensure that the machine’s performance, accuracy, and durability meet the highest standards.

Strict Quality Control System

- XTlaser has established a strict quality control system covering the entire process from raw material procurement to the delivery of laser tube cutting machines.

- All raw materials undergo rigorous screening and inspection to ensure that machine quality meets the requirements of the source.

Multiple Validation Tests

- During the production process, each laser tube cutting machine undergoes repeated testing and validation, including performance testing, accuracy testing, stability testing, etc.

- Only when all test items are passed and meet predetermined standards can the machine be sold.

Continuous Improvement and Feedback Mechanism

- XTlaser values customer experience actively listens to customer needs and collects feedback.

- Continuous improvement of product design, process flow, and quality control system to enhance the performance and quality level of laser tube cutting machines.

Timely After-Sales Support

- We provide timely and comprehensive after-sales support, from machine installation to operation training, to machine maintenance and troubleshooting.

- After-sales support personnel are online 7x24x365 to provide uninterrupted technical support to customers.

Contact Us

Not sure if your pipes are suitable for XTlaser’s laser tube cutting machine? Contact us for the most professional consulting services.

Why Choose Xtlaser’s Tube Laser Cutting Machine?

In addition to the efforts mentioned above that XTlaser has made for machine quality, there are many reasons why more and more customers trust and choose our laser tube cutting machine.

Competitive Prices

Compared with other laser cutting machine suppliers, we have our factory and workers. Customers can purchase machines directly from the source without intermediaries making a profit. In addition, we continuously reduce the profit margin of the machines, allowing customers to enjoy lower prices for laser tube cutting machines.

Long-Term After-Sales Service

XTlaser provides two years after-sales guarantee for each customer who purchases a metal pipe laser cutting machine. We will provide free repair or replacement of damaged parts during use.

Free Training Materials

We understand the excitement and hesitation of customers when they receive laser tube cutting machines. XTlaser provides comprehensive materials, including user manuals, machine debugging videos, training videos, etc., to allow customers to install and learn how to operate the machine in a shorter time.

Top Speed Delivery

XTlaser understands that customers are eagerly awaiting the completion of machine production. Standard laser tube cutting machines can be shipped within 30 days. Non-standard models can be shipped within 45 days.

Applications of Tube Fiber Laser Cutting Machine

Whether it is sports equipment, oil pipelines, or chemical equipment, XTlaser’s laser tube cutting machines play a crucial role in accurately and efficiently manufacturing various components.

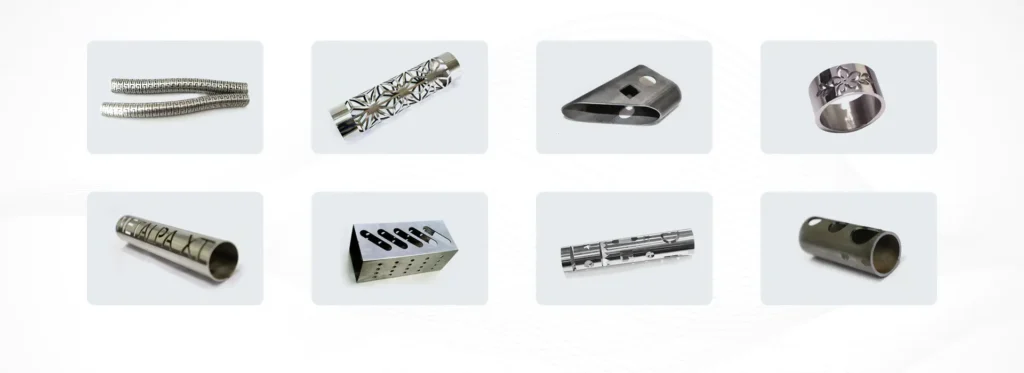

Laser Cutting Machine Samples for Metal

Here are some samples of cuts made by the fiber laser pipe cutting machine.

Frequently Asked Questions

- Improved cutting accuracy and efficiency: Laser tube cutting machines can accurately cut metal tubes, achieve high-precision batch production, and improve production efficiency.

- Compatibility with multiple materials: Laser tube cutting machines can cut various metal materials, including carbon steel, stainless steel, silicon steel, aluminum alloys, etc.

- Complex geometries: Laser tube cutting machines can cut not only single shapes but also complex geometries, creating innovative product designs.

- Cost savings: Compared with traditional cutting methods, laser tube cutting machines have smaller cutting gaps, reducing material waste; high cutting accuracy reduces the cost of secondary processing.

- Enhanced automation and integration as needed: Seamlessly integrate into existing manufacturing systems or add automatic loading and unloading systems to simplify production processes and reduce labor requirements.

XTlaser was established in 2004 and has a history of 20 years so far. As of now, XTlaser's laser cutting machines have covered more than 180 countries and regions. There are multiple after-sales service points overseas, providing emergency after-sales service within 3 hours.

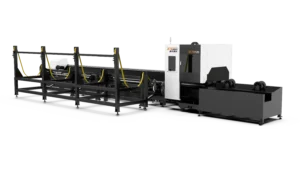

XTlaser produces a variety of models, including the popular high power laser cutting machines and three chucks laser pipe cutting machines. If you need to cut large metal sheets, XTlaser's ultra-large laser cutting machines are the best choice.

In addition, XTlaser also supplies laser marking machines, laser welding machines, and laser cleaning machines. If needed, you can contact us.

XTlaser has laser tube cutting machines that can meet the cutting needs of most customers, as well as three-chuck fiber laser pipe cutting machines with super-processing capabilities and ultra-short tailings.

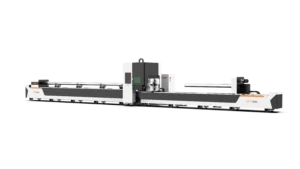

Moreover, if you need to cut both metal sheets and tubes with lasers, the plates and pipes fiber laser cutting machine is the best choice. It can efficiently cut metal tubes and sheets for you.

If you want to know the details of related models, please contact us. XTlaser will arrange for professional consultants to answer your questions.

Related Products

Related products

-

Laser Cutting Machine

HR Series H Beam Laser Cutting Machine

-

Automation Equipment

TK-series Automatic Feeding High-speed Pipe Cutting Machine

-

Automation Equipment

TP-series Three Chucks Fiber Laser Pipes Cutting Machine

-

Tube Laser Cutting Machine

T-series Laser Cutting Machine for Tubes