Mașină de tăiat cu laser pentru tuburi metalice în diferite industrii

Aplicarea pe scară largă a tehnologiei de tăiere a tuburilor cu laser

Tehnologia de tăiere cu laser a evoluat treptat de la tăierea foilor la tăierea țevilor metalice. Nașterea și aplicarea mașinii profesionale de tăiat tuburi cu laser a îmbunătățit considerabil eficiența prelucrării tuburilor metalice.

Profesionale mașină de tăiat tuburi metalice poate înlocui găurirea mecanică, frezarea, tăierea, ștanțarea sau curățarea bavurilor și alte echipamente și unelte dure care necesită un proces diferit de prelucrare a tuburilor metalice, pentru a realiza structura complexă a tubului de subtăiere, șanfrenare, canelare etc., poate fi utilizat pe scară largă în prelucrarea foilor metalice, ustensile de bucătărie, echipamente de fitness, mobilier și corpuri de iluminat, protecția clădirilor și alte industrii.

Ce vă poate ajuta să procesați mașina de tăiere cu laser a tuburilor metalice?

Gradul de practicabilitate al tehnologiei de tăiere cu laser continuă să se îmbunătățească, mașină de tăiat cu laser tuburi metalice este utilizat pe scară largă în diverse industrii.

Industria mobilei

În industria mobilei, multe canapele metalice, mese, paturi, dulapuri etc. necesită mașini de tăiat tuburi cu laser pentru tăiere. Pentru cantități mari de tuburi, mașini de tăiat tuburi cu laser cu încărcare automată poate fi de asemenea utilizat.

Iluminat metalic

Prelucrarea tuburilor metalice de la lampă este, de asemenea, inseparabilă de mașina de tăiat tuburi cu laser. Formele neregulate și golurile pot fi realizate de mașina de tăiat tuburi cu laser XT LASER.

Balustradă

Tăietorul de tuburi cu laser XT LASER poate satisface aplicațiile de balustradă stradală, balustradă peisagistică, balustradă de scară, balustradă de centură verde și așa mai departe. Spațiul dintre găurile pentru stâlpi și tuburile parapetului tăiat cu laser poate fi mai mic de 1 mm, îmbunătățind în mod eficient calitatea și estetica parapetului.

Industria bicicletelor

Cadrele bicicletelor sunt realizate din tuburi, materiale comune, cum ar fi aliajul de aluminiu, aliajul de titan, fibra de carbon etc. În comparație cu prelucrarea tradițională a tuburilor, mașina de tăiat tuburi cu laser nu numai că are mai puține procese și o eficiență mai mare, dar, de asemenea, taie o calitate mai bună a piesei de prelucrat.

Contactați-ne

Alegeți o mașină de tăiat cu laser de calitate fiabilă pentru proiectul dvs. de prelucrare a tablelor metalice.

Procesul de tăiere

În domeniul tăierii tuburilor cu laser, procesul de tăiere este o verigă cheie în determinarea calității și productivității produsului. Utilizarea echipamentului de tăiere cu laser a tuburilor XT LASER este foarte simplă, trebuie doar să urmați cei trei pași de mai jos.

Parametrii de setare

Setați parametrii de tăiere în conformitate cu desenele de proiectare.

Poziționare și prindere

Prindeți bine tuburile pe masă cu un dispozitiv de fixare.

Începeți gravarea!

Porniți tăietorul laser și începeți tăierea.

Care este cea mai bună mașină de tăiat cu laser pentru tuburi metalice?

Indiferent de dimensiunea și grosimea panoului metalic cu care lucrați, la XT LASER veți găsi echipamentul laser de care aveți nevoie.

XT LASER auto-alimentare mașină de tăiat tuburi cu laser

Gama de strângere

φ10-120 mm

φ10-160 mm

Putere (Watt)

1500W/2000W

3000W/4000W

Mașina de tăiat tuburi cu laser din seria TK este echipată cu un sistem automat de încărcare care permite distribuirea și încărcarea pachetelor complete de tuburi metalice și scurtează intervalul de procesare.

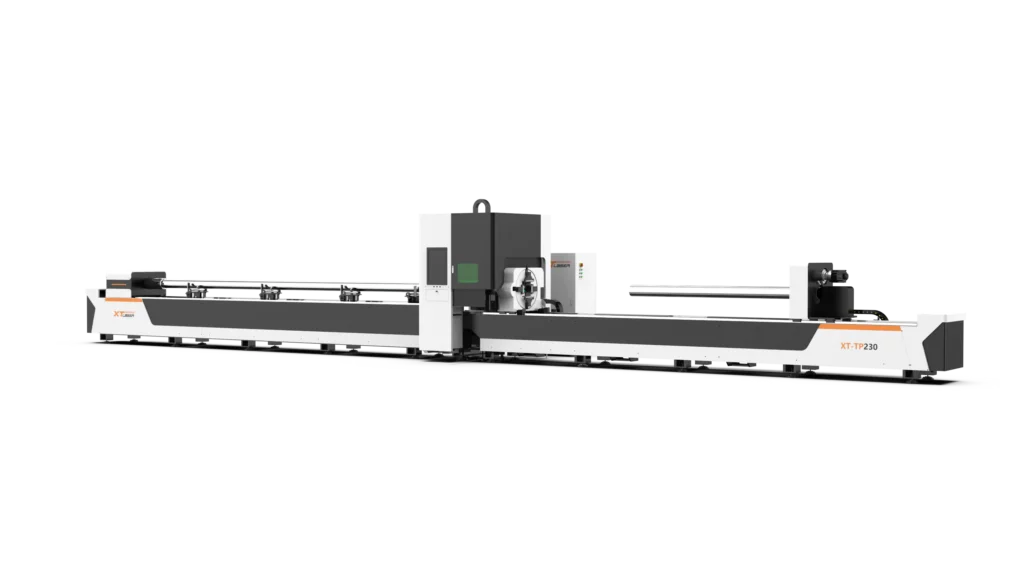

XT LASER TP-serie trei mandrine laser tub de tăiere mașină

Gama de strângere

φ20-240mm

Putere (Watt)

1500W-6000W

XT LASER Mașina de tăiat tuburi cu laser cu trei mandrine este echipată cu trei mandrine rezistente pentru tăierea tuburilor mai grele. După așezarea atentă, risipa de material poate fi redusă și utilizarea materialului poate fi îmbunătățită.

XT LASER Mașină de tăiat cu laser pentru tuburi metalice din seria T

Gama de strângere

φ20-240 mm

φ20-360 mm

Putere (Watt)

1500W-4000W

XT LASER T-series Standard Laser Tube Cuttting Machine este echipat cu un sistem special inteligent CNC pentru a tăia eficient tuburi pătrate, rotunde și ovale.