Qual é o preço da máquina de limpeza a laser? É adequada para si?

No atual cenário de fabrico e manutenção, a eficiência e a precisão são fundamentais. Os métodos de limpeza convencionais envolvem produtos químicos agressivos ou processos manuais que demoram muito tempo. É aqui que uma máquina de limpeza a laser entra em ação, uma vez que realiza a mesma tarefa de uma forma mais rápida, segura e ecológica. Mas com uma gama de modelos e caraterísticas disponíveis, é muito importante compará-los e perceber se esta solução é adequada para si. Este artigo analisa a limpeza a laser, a sua utilização e vantagens e os vários factores que afectam o preço da máquina de limpeza a laser. Examinaremos também as diferentes gamas de preços e ajudá-lo-emos a determinar se o investimento numa máquina de limpeza a laser se adequa às suas necessidades e orçamento.

O que é uma máquina de limpeza a laser?

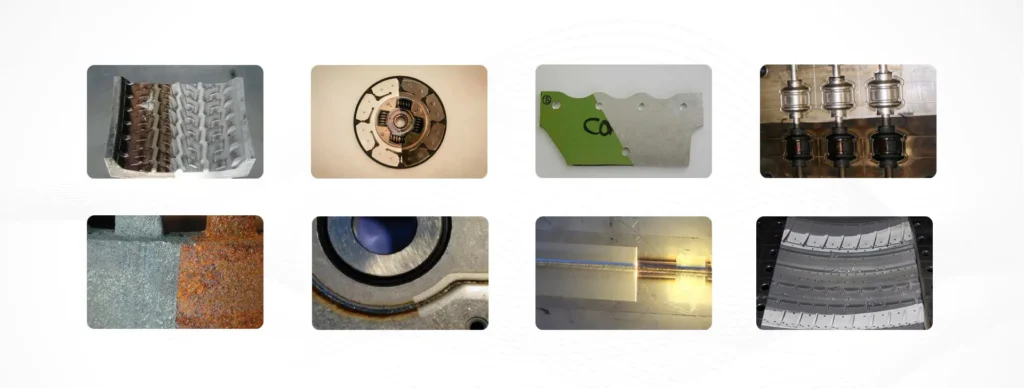

A máquina de limpeza a laser utiliza um raio laser extremamente potente para remover impurezas, películas de óxido e contaminantes em peças metálicas e não metálicas. Durante o processo de limpeza, a energia laser incide diretamente na superfície das peças, fazendo com que a camada indesejada se evapore ou desintegre sem qualquer dano térmico na camada inferior. Este processo é preciso, controlado e altamente eficaz para uma vasta gama de aplicações de limpeza.

XT LASER - Soluções para limpeza a laser Máquina

Para satisfazer os requisitos de vários processos, as máquinas de limpeza a laser estão disponíveis em diferentes configurações. De entre as muitas, há dois tipos que tendem a ser os mais populares:

- Portabilidade: Tal como o nome indica, trata-se de unidades com estruturas compactas e leves e, por conseguinte, fáceis de utilizar em termos de deslocação.

- Flexibilidade: Ideal para as áreas de difícil acesso, geometrias complexas ou nos casos em que apenas uma pequena área tem de ser limpa.

- Aplicações: São muito utilizados na manutenção de veículos, na limpeza de moldes, no restauro de obras de arte e na limpeza industrial em pequena escala.

- Preço: Em comparação com as máquinas robóticas de limpeza a laser, o seu preço tende a ser mais baixo, tornando-se assim acessível a pequenas oficinas e empresas.

- Automação: Estes sistemas combinam uma cabeça de limpeza a laser com um braço robótico, de modo a que as máquinas possam efetuar a limpeza automática sem a intervenção humana.

- Precisão e consistência: Como sabemos, os robots não são pessoas e, por isso, são robots que podem ser programados para seguir trajectos precisos e repetíveis quando se deslocam. Isto pode ser útil quando se tem de limpar grandes áreas ou objectos com superfícies complicadas.

- Eficiência: A máquina robótica de limpeza a laser aumentaria imenso a limpeza, especialmente no caso de tarefas de limpeza repetitivas.

- Segurança: A automatização reduz a exposição humana a ambientes de limpeza potencialmente perigosos.

- Aplicações: Os sistemas robóticos permitem a limpeza em grande escala em indústrias como a automóvel, a aeroespacial e a da construção naval.

- Preço: Devido à complexidade e sofisticação da tecnologia, o preço da máquina de limpeza por laser industrialpara sistemas robóticos é normalmente mais elevado.

Escolher o caminho certo Tipo

Há factores críticos a considerar na decisão de utilizar uma máquina robótica de limpeza a laser ou uma máquina portátil.

- Escala de funcionamento: As unidades portáteis são adequadas para trabalhos mais pequenos e limpeza pontual, enquanto os sistemas robóticos se destacam em aplicações de grande escala e de grande volume.

- Complexidade da tarefa: As máquinas manuais oferecem flexibilidade para formas complexas e áreas de difícil acesso, enquanto os robots são ideais para a limpeza consistente de superfícies grandes e uniformes.

- Orçamento: As unidades portáteis são geralmente mais económicas.

- Nível de automatização necessário: Se as suas operações exigem um elevado rendimento e uma intervenção manual mínima, um sistema robótico pode ser a melhor escolha.

Ao compreender as diferenças entre estes tipos, pode selecionar a máquina de limpeza a laser que melhor se adapta às suas necessidades e orçamento.

Quais são as vantagens da limpeza a laser?

Há várias formas de a limpeza a laser ser melhor do que os métodos tradicionais:

- Precisão: A limpeza a laser baseia-se num feixe de laser focado para atingir determinados contaminantes, permitindo a limpeza selectiva da superfície de um objeto sem causar danos nos materiais circundantes. É o exemplo perfeito de limpeza de precisão.

- Não abrasivo: Ao contrário de técnicas como o jato de areia, a limpeza a laser não tem contacto, preservando a integridade da superfície.

- Amigo do ambiente: Não são utilizados produtos químicos ou solventes agressivos nas operações, o que significa que a limpeza posterior terá um menor impacto ambiental e minimizará consideravelmente os resíduos.

- Eficiência: Em comparação com os métodos tradicionais, a limpeza a laser é notavelmente mais rápida, melhorando assim consideravelmente a eficiência.

- Versatilidade: É aplicável a uma série de materiais, incluindo metal, madeira, plástico e pedra.

Tipos de máquinas de limpeza a laser: Limpadores a laser contínuos e limpadores a laser pulsado

Limpadores a laser contínuos

As máquinas de limpeza a laser contínuo emitem um feixe de laser contínuo com uma potência de saída constante. A absorção do laser pelo material contaminante provoca o seu aquecimento, vaporização ou mesmo fusão. Na fase operacional, o feixe de limpeza a laser emitido é contínuo e, com o feixe direcionado para o alvo, a área pretendida acumula calor, o que é útil quando é necessário remover revestimentos espessos, ferrugem ou quaisquer contaminantes difíceis.

Aparelhos de limpeza a laser pulsado

Em contraste com os aparelhos de limpeza a laser contínuos, os aparelhos de limpeza a laser pulsados utilizam rajadas de laser curtas e de alta energia, em vez de ondas contínuas para efeitos de limpeza. Todos estes impulsos únicos fornecem uma potência de pico extrema, o que significa que existe uma grande produção de energia num período de tempo extremamente pequeno. Por conseguinte, há uma rápida expansão e aquecimento dos contaminantes na sua superfície quando esta energia é aplicada, forçando a substância a explodir ou a separar-se do substrato, sem que haja danos consideráveis no material da superfície subjacente.

Que factores afectam fibra preço da máquina de limpeza a laser?

Ao considerar o custo de uma máquina de limpeza a laser, é importante notar que há certos factores críticos que entram em jogo, incluindo:

- Potência do laser: Quanto maior a potência (por exemplo, em termos de uma máquina de limpeza a laser de 1000W em oposição a uma máquina de limpeza a laser de 100W), geralmente significa uma limpeza mais rápida e a capacidade de lidar com contaminantes mais difíceis. Devido ao aumento das exigências de potência, o custo médio da máquina de limpeza a laser industrial seria mais elevado.

- Portabilidade: O preço da máquina de limpeza a laser portátil e o preço da máquina de limpeza a laser portátil são mais baixos em comparação com unidades maiores e fixas.

- Caraterísticas: O custo pode aumentar se existirem caraterísticas adicionais, tais como frequência de impulsos ajustável (máquina de limpeza a laser por impulsos), percursos de limpeza automatizados e sistemas de recolha de poeiras incorporados.

- Fonte de laser: O preço da máquina de limpeza a laser de fibra varia, uma vez que é durável e gera menos resíduos.

Quais são as gamas de preços dos diferentes tipos de máquinas de limpeza a laser?

100W - 500W: O limpeza a laserner preço da máquina desta gama está entre os mais económicos e começa em cerca de $2.000. É mais indicado para tarefas ligeiras e aplicações mais pequenas.

500W - 1000W: O preço deste tipo de máquinas varia entre $3.000 e $5.000. Este tipo de máquinas pode ser utilizado para aplicações industriais.

1000W e superior: Os preços podem exceder $50.000 e ir muito além de $100.000 para sistemas de alta potência concebidos para limpeza pesada e aplicações especializadas.

Onde comprar uma máquina de limpeza a laser?

Fabricantes originais: É melhor e mais eficaz comprar aos fabricantes originais, como a XT LASER, para evitar problemas de produtos de qualidade inferior e a recusa de qualquer apoio difícil.

Distribuidores autorizados locais: Os distribuidores autorizados ajudam a considerar quaisquer questões locais e a auxiliar na assistência.

Mercado da Amazon: Embora o preço da máquina de limpeza a laser na Amazon tenha muitas opções de escolha, é prudente fazer uma ampla pesquisa sobre os vendedores e as avaliações dos compradores.

Conclusão

A tecnologia de limpeza a laser oferece uma alternativa atraente aos métodos de limpeza tradicionais, com benefícios que incluem precisão, eficiência e respeito pelo ambiente. Embora laser ferrugem preço da máquina de limpeza é uma consideração importante, compreender os factores que influenciam o custo e explorar as opções disponíveis pode ajudá-lo a tomar uma decisão informada.

Quer esteja à procura de um preço da máquina de limpeza a laser profissional para utilização industrial ou uma solução mais económica para tarefas mais pequenas, avalie cuidadosamente as suas necessidades e orçamento. Considere os benefícios a longo prazo e o potencial retorno do investimento que a limpeza a laser pode trazer às suas operações.