مزايا ماكينة القطع بالليزر في معالجة الصفائح المعدنية

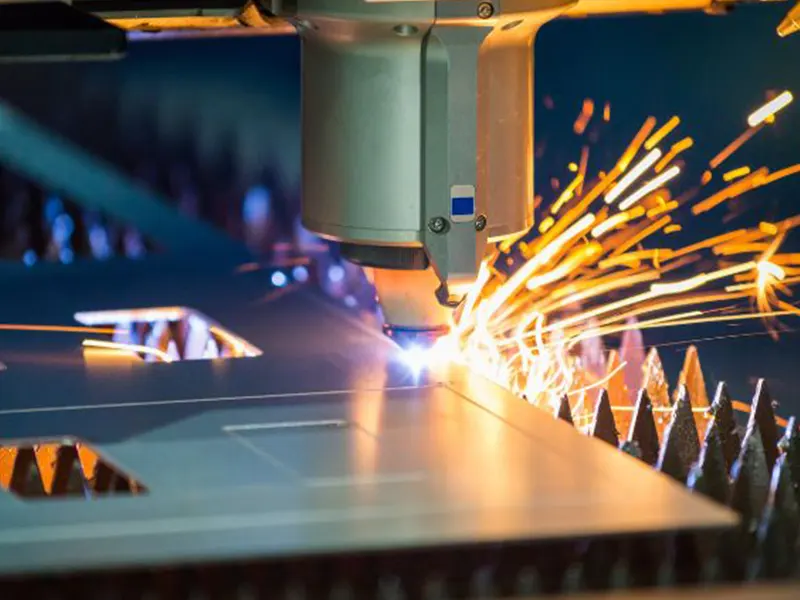

ماكينة القطع بالليزر في معالجة الصفائح المعدنية

ماكينات القطع التقليدية غير فعالة وغير دقيقة، وغير قادرة على معالجة الأجزاء الدقيقة، وتتطلب فنيين ذوي خبرة لتشغيلها. ومع ذلك، فإن آلة القطع بالليزر مختلفة.

يتميز القطع بالليزر بخصائص الدقة العالية، وسرعة القطع السريع، ولا يقتصر على نمط القطع، والتعشيش التلقائي، وتوفير المواد، والقطع السلس، وتكلفة المعالجة المنخفضة.

منطقة القطع بالليزر المتأثرة بالحرارة صغيرة، وتشوه اللوحة صغير، وشق القطع ضيق؛ لا يوجد ضغط ميكانيكي على الشق، ولا يوجد نتوءات قص؛ دقة معالجة عالية، وتكرار جيد، ولا يوجد ضرر على سطح المادة. يمكن للبرمجة بنظام التحكم الرقمي باستخدام الحاسب الآلي معالجة أي برنامج، ويمكن أن تكون بتنسيق كبير لقطع اللوحة بالكامل، ولا حاجة لفتح القالب، مع مزايا اقتصادية وموفرة للوقت.

ما الذي يمكنك تحقيقه باستخدام ماكينة القطع بالليزر؟

سواءً كنت ترغب في صنع خزانات هيكلية أو أواني وأواني ذات حواف ناعمة وأدوات مطبخ وما إلى ذلك، فإن ماكينات الليزر XT LASER ستتيح لك إنتاج منتجات مُرضية.

الهياكل والخزائن

بالنسبة للهياكل والخزانات التي تتطلب دقة أبعاد صارمة، فإن XT LASER قادرة على قطع الألواح بدقة من مختلف الأحجام بحيث يمكن تركيب الهياكل والخزانات معًا بإحكام. يمكن أن تكون الألواح المقطوعة عالية الدقة أكثر ملاءمة لعمليات التثبيت واللحام وغيرها من العمليات، مما يحسن كفاءة التجميع وجودة المنتج.

الأواني والمقالي أدوات المطبخ

يمكن لماكينة القطع بليزر الألياف الليزرية XT LASER أن تصنع الأواني والمقالي وأدوات المائدة بأشكال فريدة وحواف ناعمة. السطح المقطوع أملس ولا يتطلب الكثير من معالجة الطحن اللاحقة، مما يوفر وقت المعالجة والتكلفة ويحسن من متانة أدوات المطبخ.

قطع غيار السيارات

عند معالجة كتلة محرك السيارة وهيكل الهيكل وأجزاء أخرى، تلعب آلة القطع بالليزر دورًا لا يمكن تجاهله. قدرتها على القطع عالي السرعة، ليس فقط لتلبية احتياجات الإنتاج الضخم، ولكن أيضًا لتعزيز الأداء العام وإنتاجية السيارة.

غلاف المعدات الإلكترونية

اتجاه تطوير المعدات الإلكترونية الرقيقة والخفيفة، والتصغير، ومتطلبات دقة المعالجة عالية بشكل متزايد. يمكن لآلة القطع بليزر الألياف الليزرية XT LASER أن تحقق قطعًا دقيقًا، ويمكنها معالجة الألواح المعدنية الرقيقة جدًا.

اتصل بنا

اختر ماكينة قطع بالليزر عالية الجودة وموثوقة لمشروعك لمعالجة الصفائح المعدنية.

عملية القطع

في مجال معالجة الصفائح المعدنية، تعتبر عملية القطع حلقة رئيسية في تحديد جودة المنتج والإنتاجية. استخدام معدات الليزر XT LASER بسيط للغاية، ما عليك سوى اتباع الخطوات الثلاث التالية.

إعداد المعلمات

اضبط معلمات القطع وفقًا لرسومات التصميم.

التموضع والتثبيت

ثبّت الصفيحة بإحكام على الطاولة باستخدام أداة تثبيت.

ابدأ النقش!

ابدأ تشغيل قاطع الليزر وابدأ القطع.

ما هي أفضل ماكينة لقطع الصفائح المعدنية بالليزر؟

مهما كان حجم وسُمك الصفيحة المعدنية التي تعمل بها، ستجد في XT LASER معدات الليزر التي تحتاج إليها.

ماكينة القطع بالليزر XT LASER H-series H-series

منطقة العمل

1500×3000 مم

2000 × 4000 مم

2000 × 6000 مم

الطاقة (وات)

1500 واط/2000 واط

3000 واط/4000 واط

تم تجهيز ماكينات القطع بالليزر من السلسلة H-Series بنظام تحكم بصري ذكي يسمح بضبط طاقة الليزر ونوع الغاز والضغط بسهولة.

ماكينة القطع بالليزر من سلسلة XT LASER GPX

منطقة العمل

1500×3000 مم

الطاقة (وات)

12000W

إذا كان لديك طلب كبير على سرعة القطع والتأثير، فإن سلسلة GPX تستحق الشراء. مجهزة بليزر بقوة 12000 واط وتسارع يصل إلى 2.8 جرام، يمكن لسلسلة GPX تحقيق سرعة قصوى تبلغ 180 متر/دقيقة في حركة واحدة.

ماكينة القطع بالليزر XT LASER W-series W-series

منطقة العمل

3100 × 13000 مم

3200 × 14000 مم

الطاقة (وات)

12000 واط - 60000 واط

نظرًا لحجمها الكبير وقوتها الكبيرة، فإن آلة القطع بالليزر هذه تستخدم على نطاق واسع لقطع الألواح المعدنية السميكة، بما في ذلك الألواح النحاسية السميكة، وألواح الفولاذ الكربوني، وألواح الفولاذ المقاوم للصدأ وما إلى ذلك.

يمكن مطابقة حجم وقوة جميع الموديلات بشكل عشوائي وفقاً لاحتياجاتك.